Troubleshooting (continued)

Mechanical or Material Output Problems

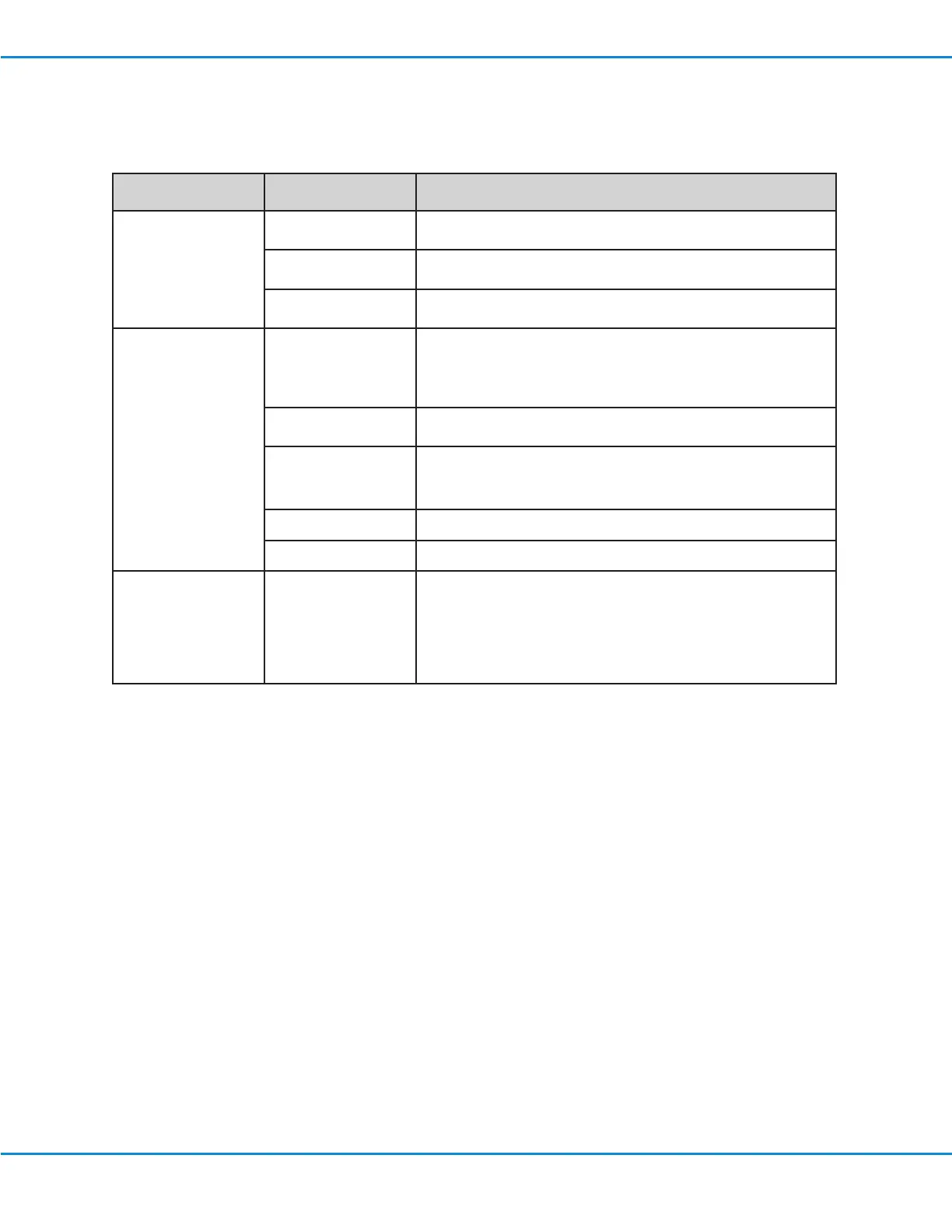

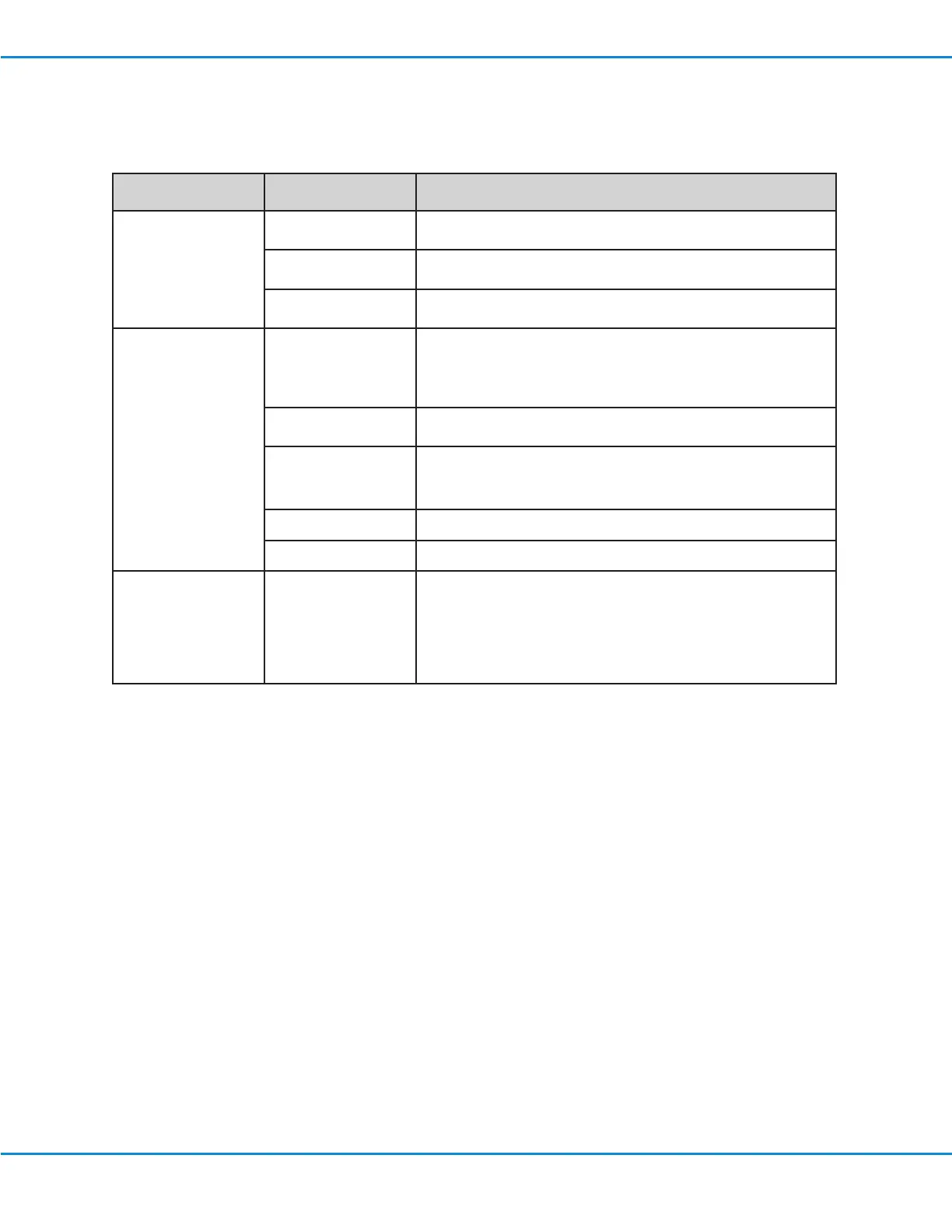

Problem Possible Cause Corrective Action

No fluid being

dispensed

Pressure too low If dispensing thicker materials, try increasing output air pressure

slightly.

Vacuum too high Reduce the vacuum setting.

Safety clip closed Ensure that the barrel adapter safety clip is not clamped shut.

Inconsistent output Dispensing tip or

barrel clogged, or

material contaminated

Check the dispensing tip, barrel, and material for possible

contamination or clogs.

NOTE: Dispensing system components are disposable. Do not

attempt to reuse.

Fluctuating factory air

supply

Check the factory air supply for pressure fluctuations and correct

as necessary.

Trapped air in the

fluid path

Air bubbles in the fluid path and entrapped air within the fluid can

cause inconsistency. For the best dispensing results, remove all

entrapped air before dispensing by purging the tip.

Vacuum too high Reduce the vacuum setting.

Safety clip closed Ensure that the barrel adapter safety clip is not clamped shut.

Material suck-back Dispensing without a

piston

Always use an appropriate piston to prevent material from being

drawn back into the dispenser. For thick- to medium-viscosity

fluids, use EFD SmoothFlow pistons. For thin, low-viscosity

fluids, use EFD LVBarrier pistons.

Another option is to use a syringe barrel adapter with a filter trap.

Refer to “Quicksilver Adapter Assembly” on page48.

UltimusPlus Series Dispensers

52 www.nordsonefd.com info@nordsonefd.com +1-401-431-7000 Sales and service of Nordson EFD dispensing systems are available worldwide.

Loading...

Loading...