1 - 55

Chapter 1 Troubleshooting

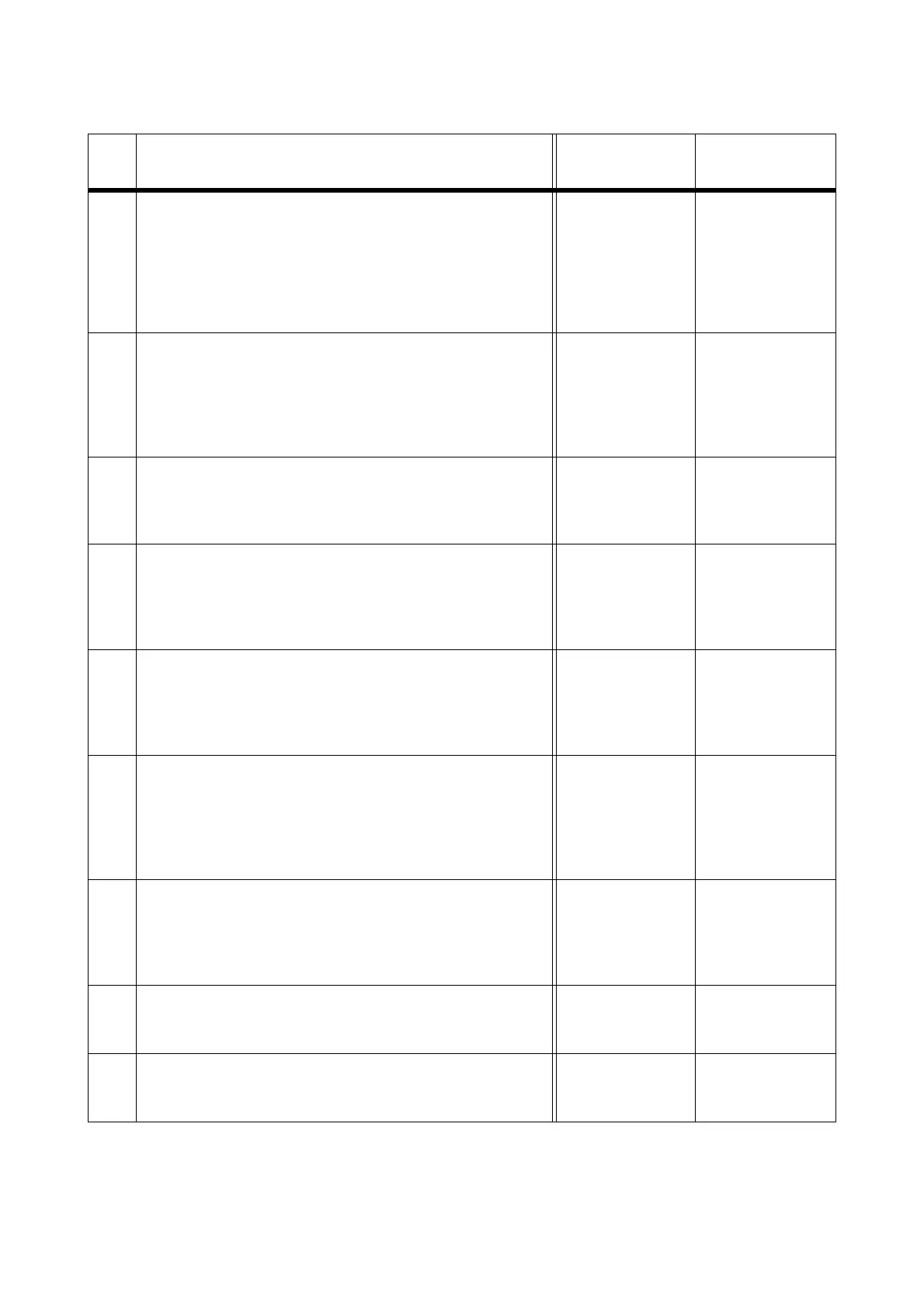

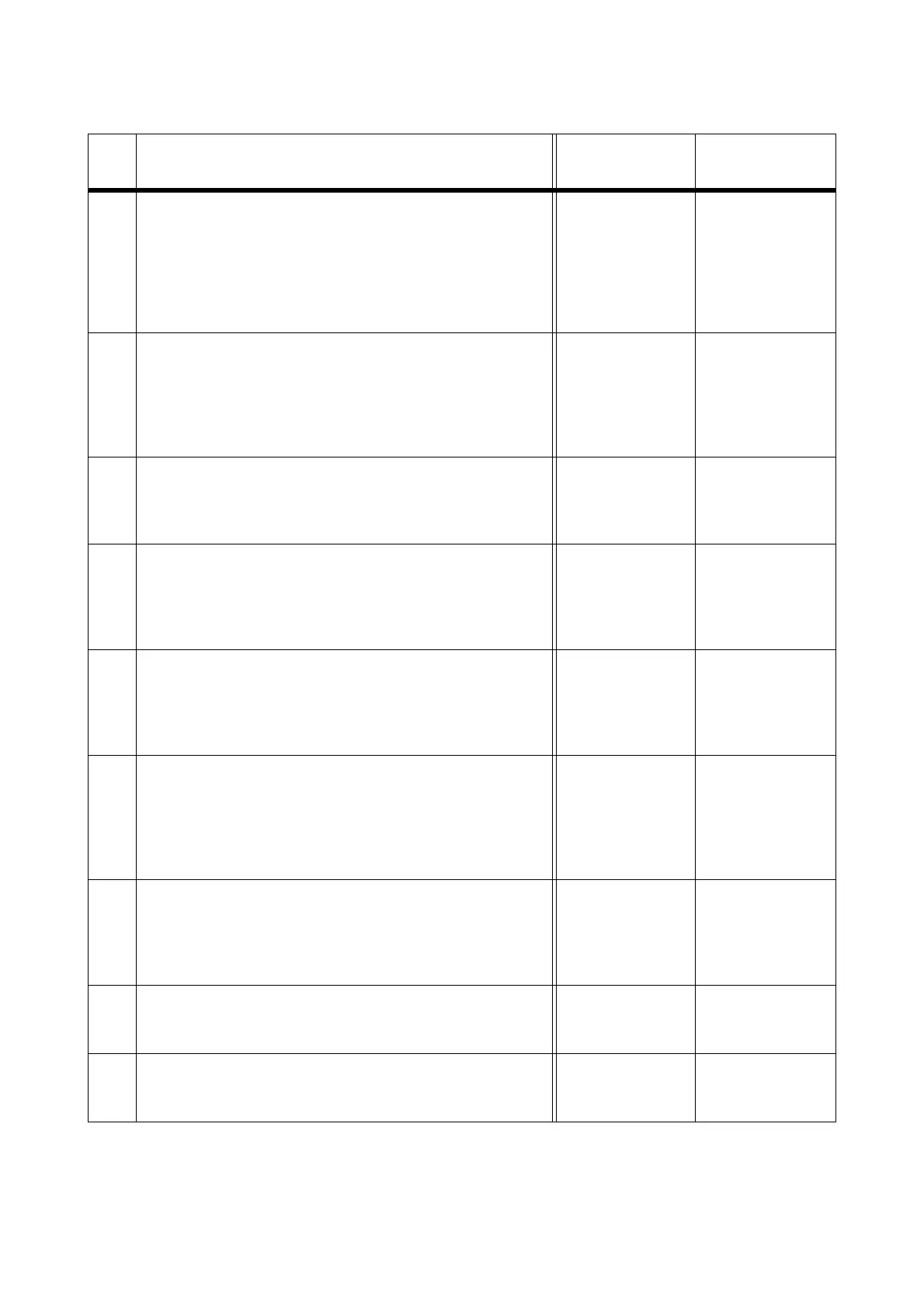

FIP2.3 ROS ASSY (PL8.1.1)

Step

Check Yes No

Possible causative parts:

ROS ASSY (PL8.1.1)

HARNESS ASSY ROS (PL8.1.2)

INTERLOCK S/W 5V (PL8.1.12)

HARNESS ASSY LVPS (PL12.1.1)

HVPS/MCU (PL12.1.19)

LVPS (PL12.1.5)

1

Checking the power to Laser Diode of ROS ASSY

Remove COVER TOP ASSY (PL1.1.7). (RRP1.4)

Disconnect P/J140 from ROS ASSY.

Install EP CARTRIDGE.

Close COVER OPEN (PL1.1.2).

Is the voltage across J140-8 <=> J140-7, 5 VDC?

Go to step 8. Go to step 2.

2

Checking INTERLOCK S/W 5V

Remove INTERLOCK S/W 5V.

Is it continuous between P/J142-1 <=> P/J142-3, when

INTERLOCK S/W 5V is pushed, and is not when released?

Go to step 3.

Replace

INTERLOCK S/W

5V. (RRP8.5)

3

Checking SWITCH I/L ASSY 5V

Remove SWITCH I/L ASSY 5V.

Is it continuous between P/J144-1 <=> P/J144-3, when

SWITCH I/L ASSY 5 V is pushed, and is not when

released?

Go to step 4.

Replace SWITCH

I/L ASSY 5V.

(RRP1.6)

4

Checking HARNESS ASSY LVPS

Disconnect P/J141 of HARNESS ASSY LVPS.

Is it conductive between P/J141-1 <=> P/J141-3 when

INTERLOCK S/W 5V and SWITCH I/L ASSY 5V are

pushed simultaneously, and is not when released?

Go to step 5.

Replace

HARNESS ASSY

LVPS.

5

Checking HARNESS ASSY ROS

Disconnect P/J14 from HVPS/MCU.

Disconnect P/J140 fcrom ROS ASSY.

Is it continuous between P/J14-1 <=> P/J140-8, when

INTERLOCK S/W 5V and SWITCH I/L ASSY 5V are

pushed simultaneously, and is not when released?

Go to step 6.

Replace

HARNESS ASSY

ROS.

6

Checking power to HVPS/MCU

Remove SHIELD PLATE LVPS. (RRP12.1)

Install EP CARTRIDGE.

Disconnect P/J41 from LVPS.

Is the voltage across P/J41-4 <=> P/J41-3, 5 VDC?

Replace LVPS.

(RRP12.3).

Go to step 7.

7

Checking HVPS/MCU for continuity

Disconnect P/J14 and P/J11 from HVPS/MCU.

Is P/J14-1 <=> P/J11-13 continuous normally?

Go to step 8.

Replace

HVPS/MCU.

(RRP12.10).

8

Checking HARNESS ASSY LVPS for continuity

Disconnect P/J11 from HVPS/MCU.

Is P/J11-13 <=> P/J41-4 continuous normally?

Go to step 9.

Replace

HARNESS ASSY

LVPS.

Loading...

Loading...