6 - 5

6 Applied Functions

OMNUC G5-series (Pulse-train Input Type) AC Servomotors and Servo Drives User’s Manual

6-1 Damping Control

6

6-1-2 Parameters Requiring Settings

3

Make the damping filter settings.

Make damping filter settings (1: Pn215, 2: Pn217, 3: Pn219, 4: Pn221).

First, set to 0.

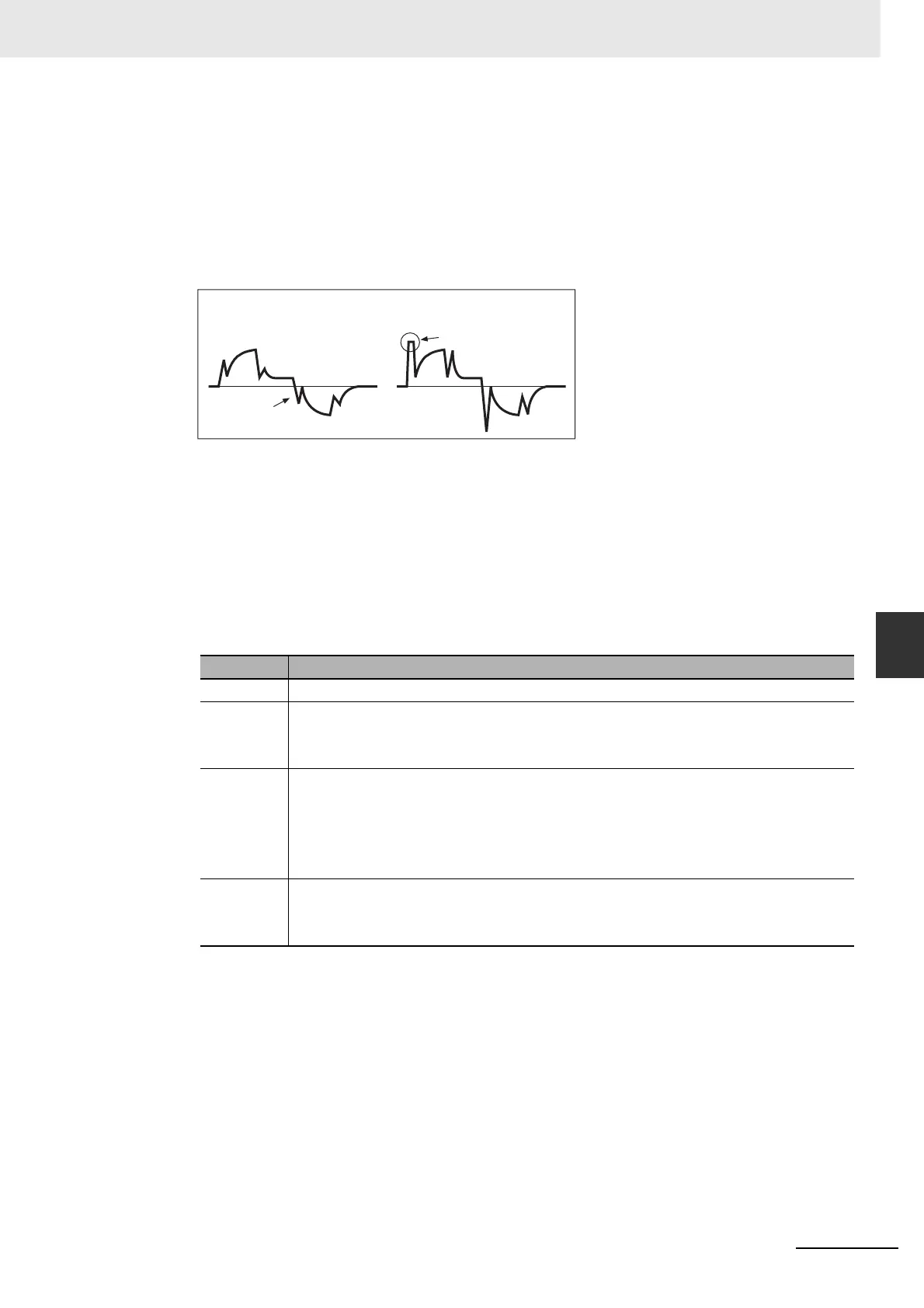

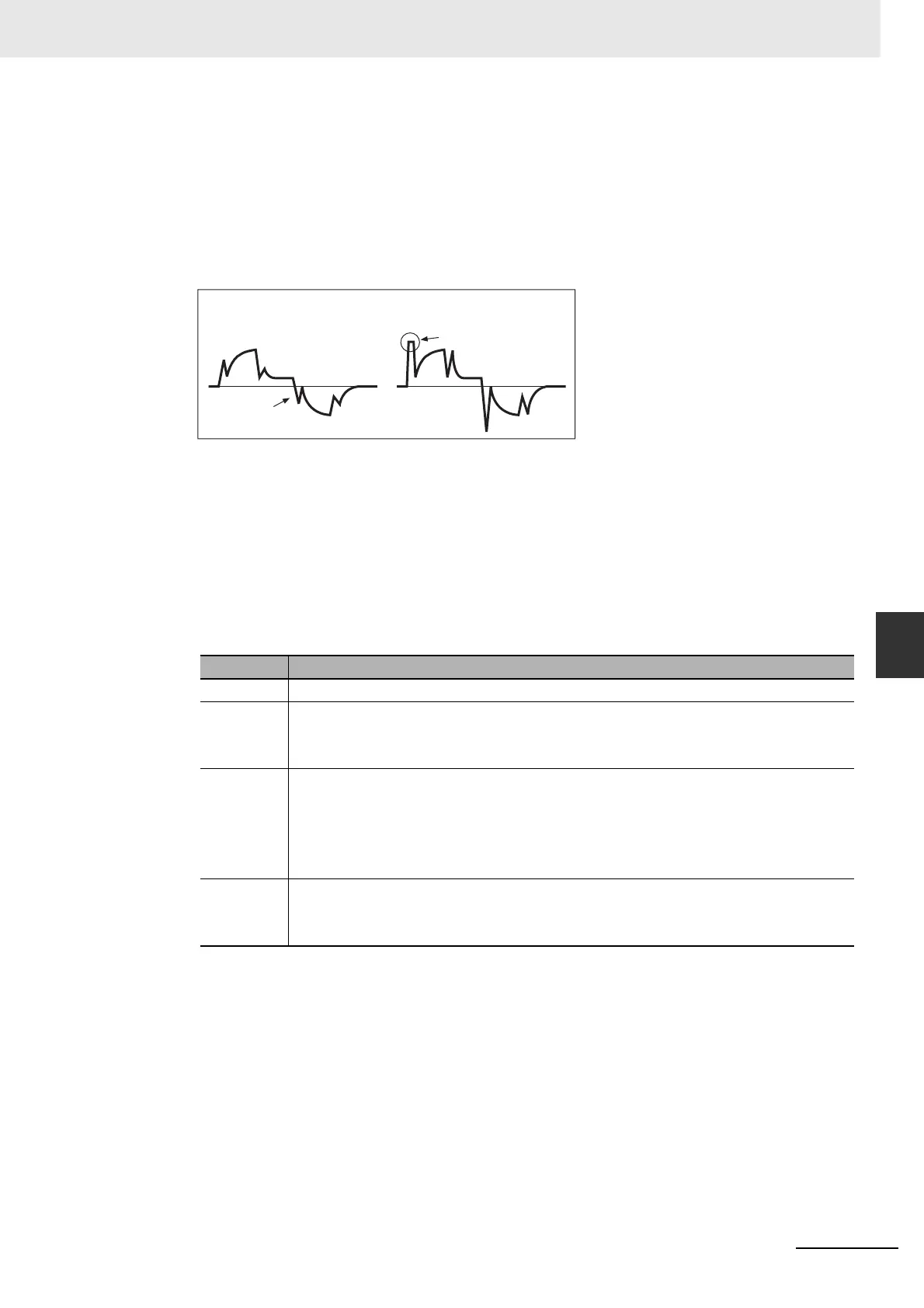

The stabilization time can be reduced by setting a large value; however, torque ripple will

increase at the command change point as shown in the following figure. Set a range that will not

cause torque saturation under actual operation conditions. The effects of vibration suppression

will be lost if torque saturation occurs.

When Damping Frequency 1 (Pn214) is set, reduce this setting if torque saturation occurs or

increase this setting to improve the operation speed. Normally 0 is set.

When Damping Filter 1 is enabled, the setting range is as follows:

Setting range: 100 ≤ Pn214 + Pn215 ≤ Pn214 x 2 or 2,000

Note When Damping Filter 1 is disabled in Damping Filter Selection (Pn213), this parameter is also

disabled.

4

Set the Damping Filter Selection (Pn213).

Damping Filter 1 to 4 can be switched according to the conditions of the machine vibration.

Set value Switching mode

0 Damping Filter 1 and 2 enabled

1 Switching via external input (DFSEL1)

When DFSEL1 is open: Damping Filter 1 and 3 enabled

When DFSEL1 is shorted: Damping Filter 2 and 4 enabled

2 Switching via external input (DFSEL1, DFSEL2)

When DFSEL1 and DFSEL2 are open: Damping Filter 1 enabled

When DFSEL1 is shorted and DFSEL2 is open: Damping Filter 2 enabled

When DFSEL1 is open and DFSEL2 is shorted: Damping Filter 3 enabled

When DFSEL1 and DFSEL2 are shorted: Damping Filter 4 enabled

3 Switching based on the command direction

During forward rotation: Damping Filter 1 and 3 enabled

During reverse rotation: Damping Filter 2 and 4 enabled

Torque

command

Torque saturation

Damping filter setting is

too large.

Damping filter setting

is appropriate.

Loading...

Loading...