A - 11

Appendices

OMNUC G5-series (Pulse-train Input Type) AC Servomotors and Servo Drives User’s Manual

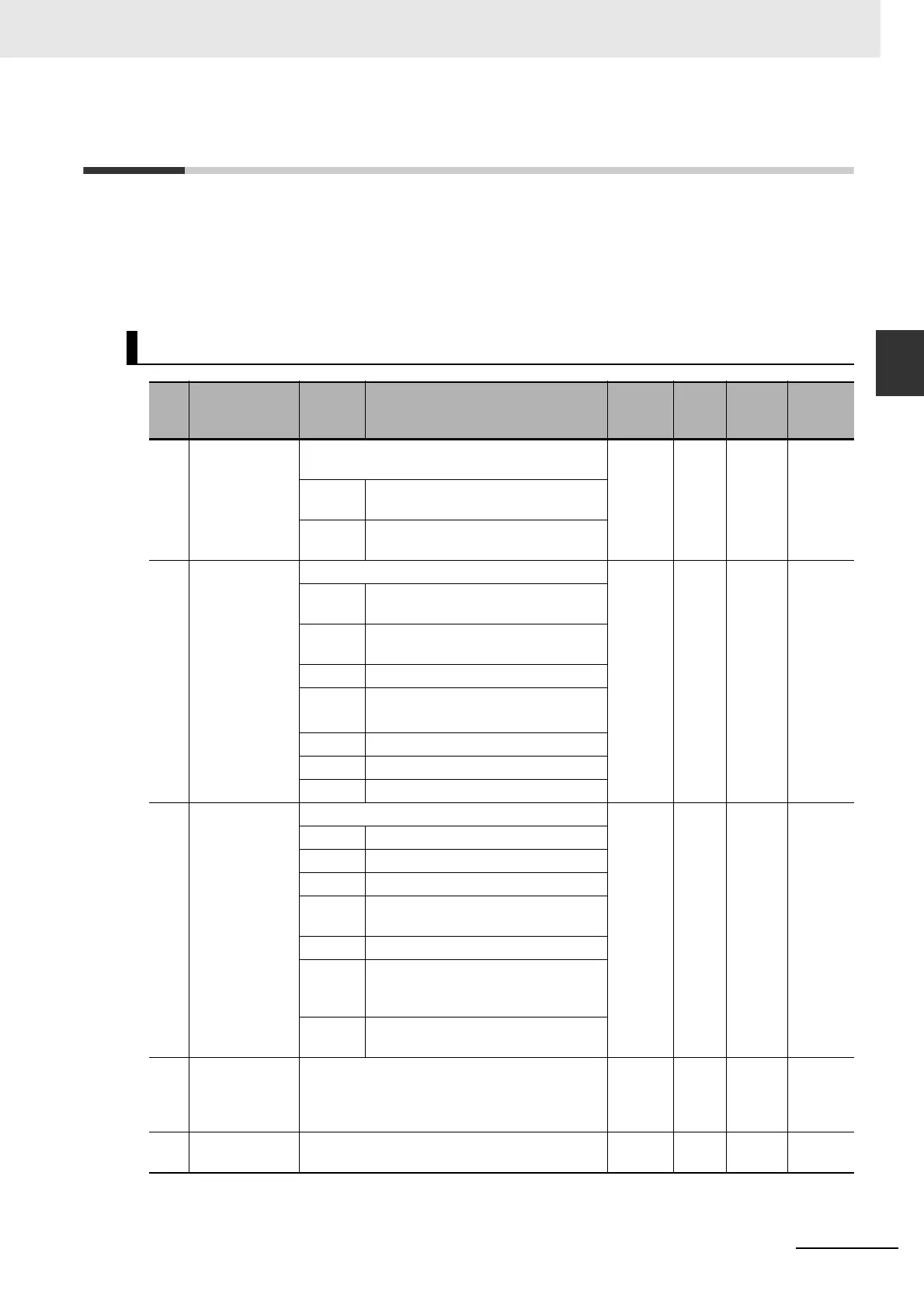

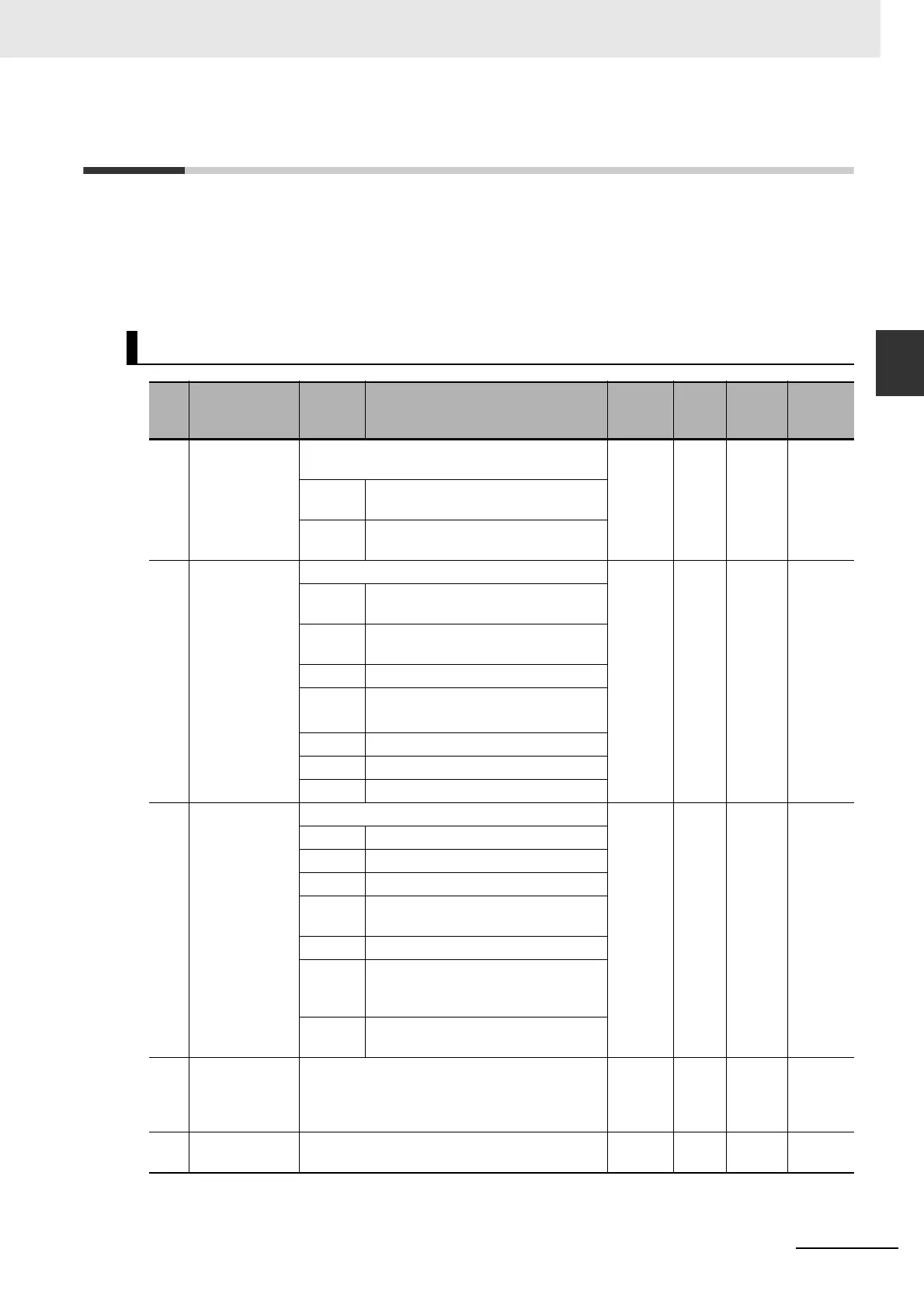

A-2 Parameter List

A

A-2 Parameter List

• Some parameters are enabled by cycling the power supply (shown in the tables below). After

changing these parameters, turn OFF the power supply, confirm that the power supply indicator is not

lit, and then turn ON the power supply again to restart the system.

• Do not change the parameters marked “Reserved.”

Do not change the set values marked “Not used” or “Reserved”.

Basic Setting Parameters

Pn

No.

Name Setting Description

Default

setting

Unit

Setting

range

Cycle the

power

supply

000 Rotation

Direction

Setting

Set the relation between the command direction

and the motor rotation direction.

1 – 0 to 1

Required

0 Forward (CW) when viewed from

shaft end for positive (+) commands

1 Reverse (CCW) when viewed from

shaft end for positive (+) commands

001 Control Mode

Selection

Select the control mode of the Servo Drive. 0 – 0 to 3

Required

0 Position control (Pulse-train

command)

1 Speed control (Internally set speed

control)

2 Reserved (Do not set.)

3 Mode 1: Position control

Mode 2: Speed control

4 Reserved (Do not set.)

5 Reserved (Do not set.)

6 Reserved (Do not set.)

002 Realtime

Autotuning

Mode Selection

Set the realtime autotuning operation mode. 1 – 0 to 6 –

0 Disabled

1 Focus on stability

2 Focus on position control

3 Used when an unbalanced load is

present on a vertical axis etc.

4 Used when friction is large

5 Used when an unbalanced load is

present on a vertical axis etc. and

friction is large

6 Used when customizing the realtime

autotuning function

003 Realtime

Autotuning

Machine

Rigidity Setting

Set the machine rigidity when realtime

autotuning is enabled.

13

*1

– 0 to 31 –

004 Inertia Ratio Set the load inertia as a percentage of the

motor rotor inertia.

250 % 0 to

10,000

–

Loading...

Loading...