10 - 17

10 Troubleshooting and Maintenance

OMNUC G5-series (Pulse-train Input Type) AC Servomotors and Servo Drives User’s Manual

10-4 Troubleshooting

10

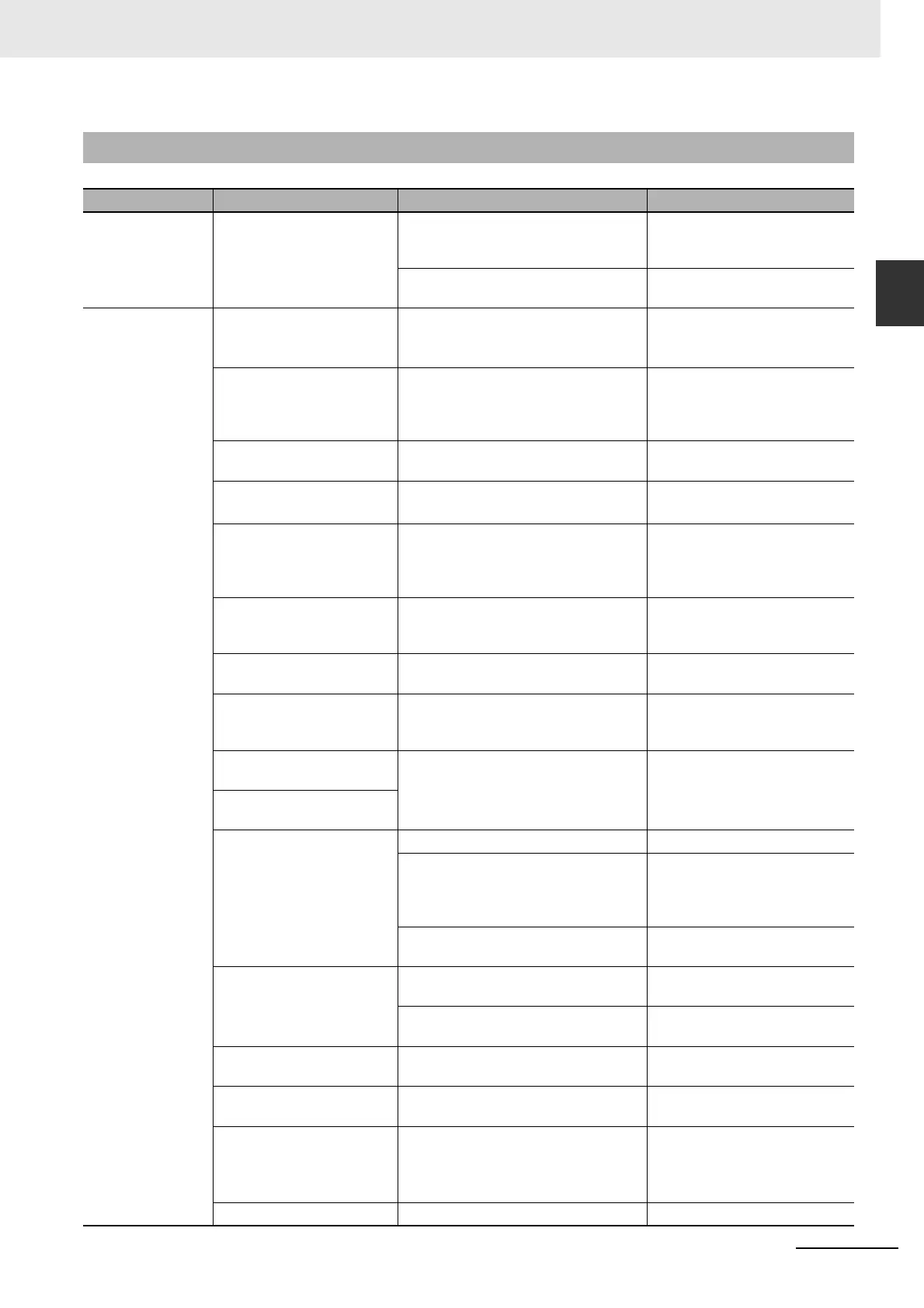

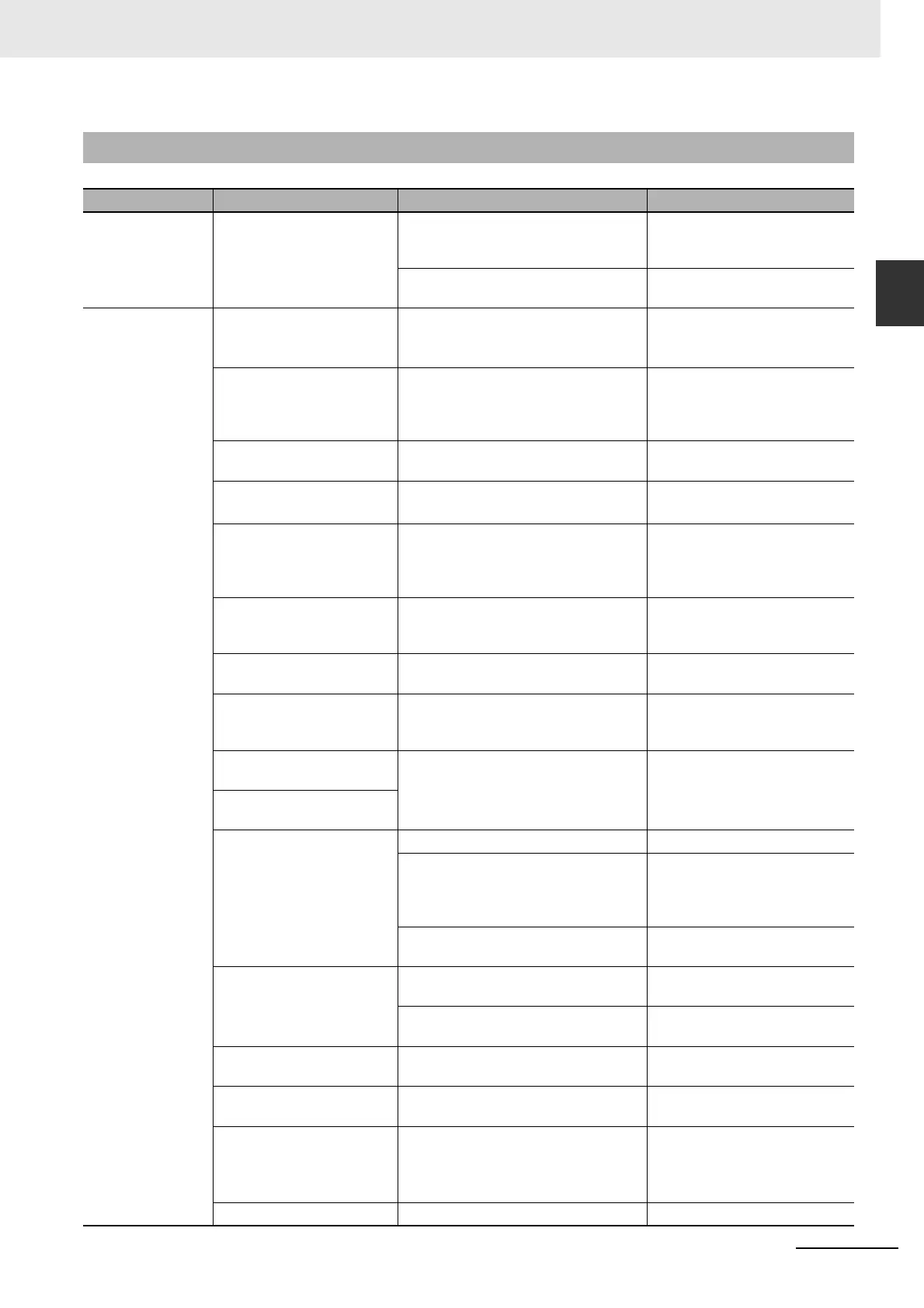

10-4-2 Error Diagnosis Using the Operation State

10-4-2 Error Diagnosis Using the Operation State

Symptom Probable cause Check items Measures

The PWR indicator

does not light

when the Servo

Drive is powered

on.

The power supply wiring is

incorrect.

Check to see if the power supply input

is within the allowed power supply

voltage range.

Supply the correct power

supply voltage.

Check to see if the power supply input

is wired correctly.

Wire correctly.

The Servomotor

does not rotate

when a command

is input from the

controller.

The Operation Command

(RUN) signal is OFF.

Check in the monitor mode if the RUN

signal turns ON/OFF.

• Input the Operation

Command (RUN) signal.

• Wire correctly.

Forward Drive Prohibition

Input (POT) or Reverse

Drive Prohibition Input

(NOT) signal is OFF.

Check in the monitor mode if the POT

and NOT signals turn ON/OFF.

•

Turn ON the POT or NOT signal.

•

Disable the parameter if the

POT or NOT signal is not used.

The control mode does not

conform to the command.

Check the value set in Control Mode

Selection (Pn001).

Set the control mode according

to the command.

The Error Counter Reset

Input (ECRST) signal is ON.

Check in the monitor mode if the

ECRST signal turns ON/OFF.

• Turn OFF the ECRST signal.

• Wire correctly.

The value set in Command

Pulse Mode Selection

(Pn007) is incorrect.

Check the command pulse type of the

controller and that of the Servo Drive.

Set the command pulse type of

the Servo Drive so that it

matches the command pulse

type of the controller.

The Zero Speed

Designation Input (VZERO)

signal is OFF.

Check in the monitor mode if the

VZERO signal turns ON/OFF.

• Turn ON the VZERO signal.

• Wire correctly.

No internally set speeds are

set.

Check the values set in Pn304 to

Pn311.

Set the desired rotation speed.

The values set in No.1 Torque

Limit (Pn013) and No.2

Torque Limit (Pn522) are 0.

Check the values set in Pn013 and

Pn522.

Restore the default set values.

The Servomotor power

cable is wired incorrectly.

Check the wiring. Wire correctly.

The encoder cable is wired

incorrectly.

The control I/O connector

(CN1) is wired incorrectly.

Check the command pulse wiring. Wire correctly.

Check the command pulse type. Set the command pulse type of

the Servo Drive so that it

matches the command pulse

type of the controller.

Check the command pulse voltage. Connect resistors appropriate

for the voltage.

Power is not supplied. Check the power supply and the PWR

indicator.

Turn ON the power supply.

Check the voltage across the power

terminals.

Wire the power-on circuit

correctly.

The speed command is

disabled.

Check to see if the speed command

input method is correct.

• Set the internal speed

correctly.

The torque command is

disabled.

Check to see if the torque command

input method is correct.

Set the torque command

correctly.

Both the CW and CCW

inputs are turned ON

simultaneously.

Check the command pulse wiring. • Input the pulse signal to

either the CW or CCW input.

• Unused input terminals must

be always OFF.

The Servo Drive is faulty. – Replace the Servo Drive.

Loading...

Loading...