Appendices

A - 12

OMNUC G5-series (Pulse-train Input Type) AC Servomotors and Servo Drives User’s Manual

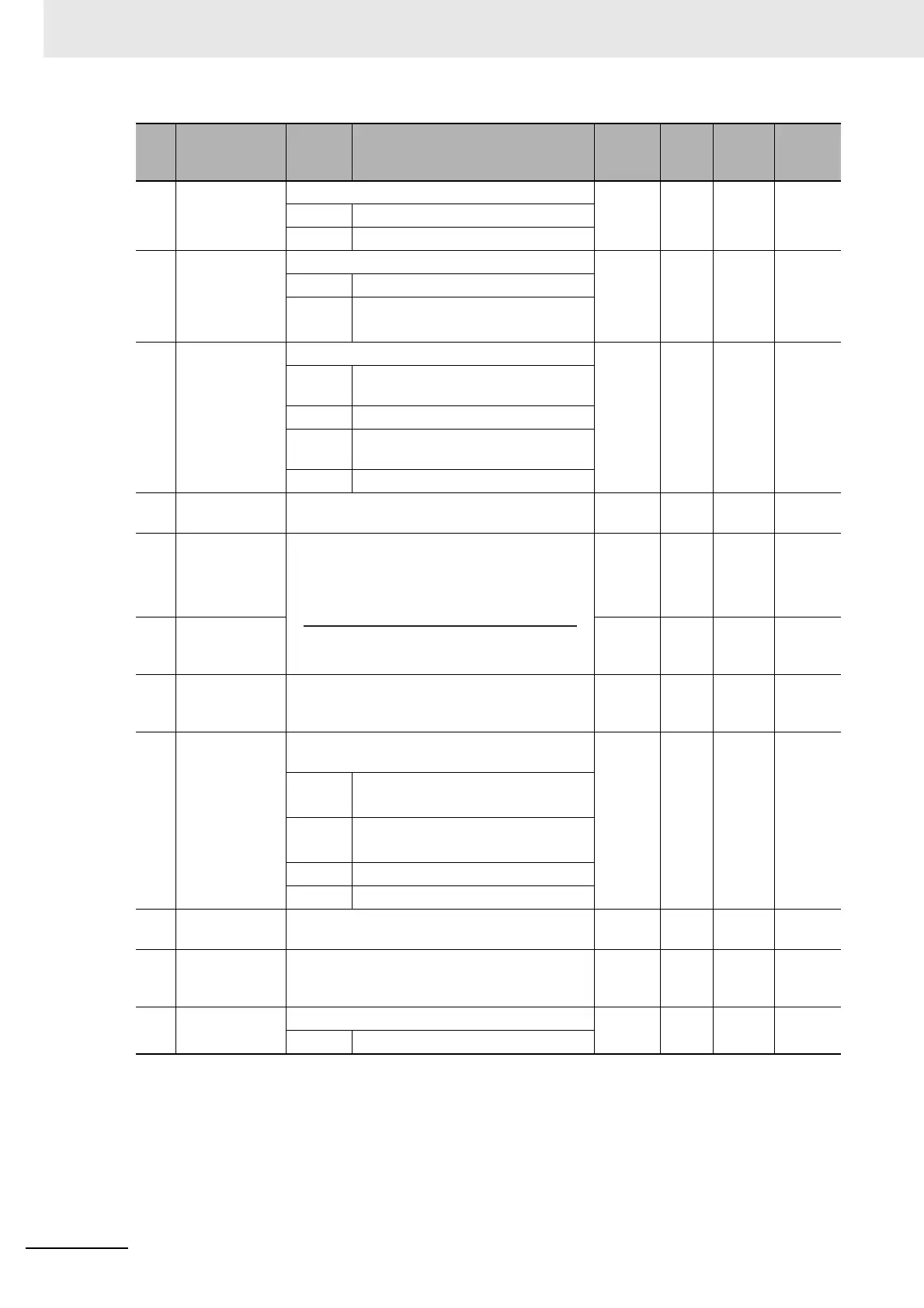

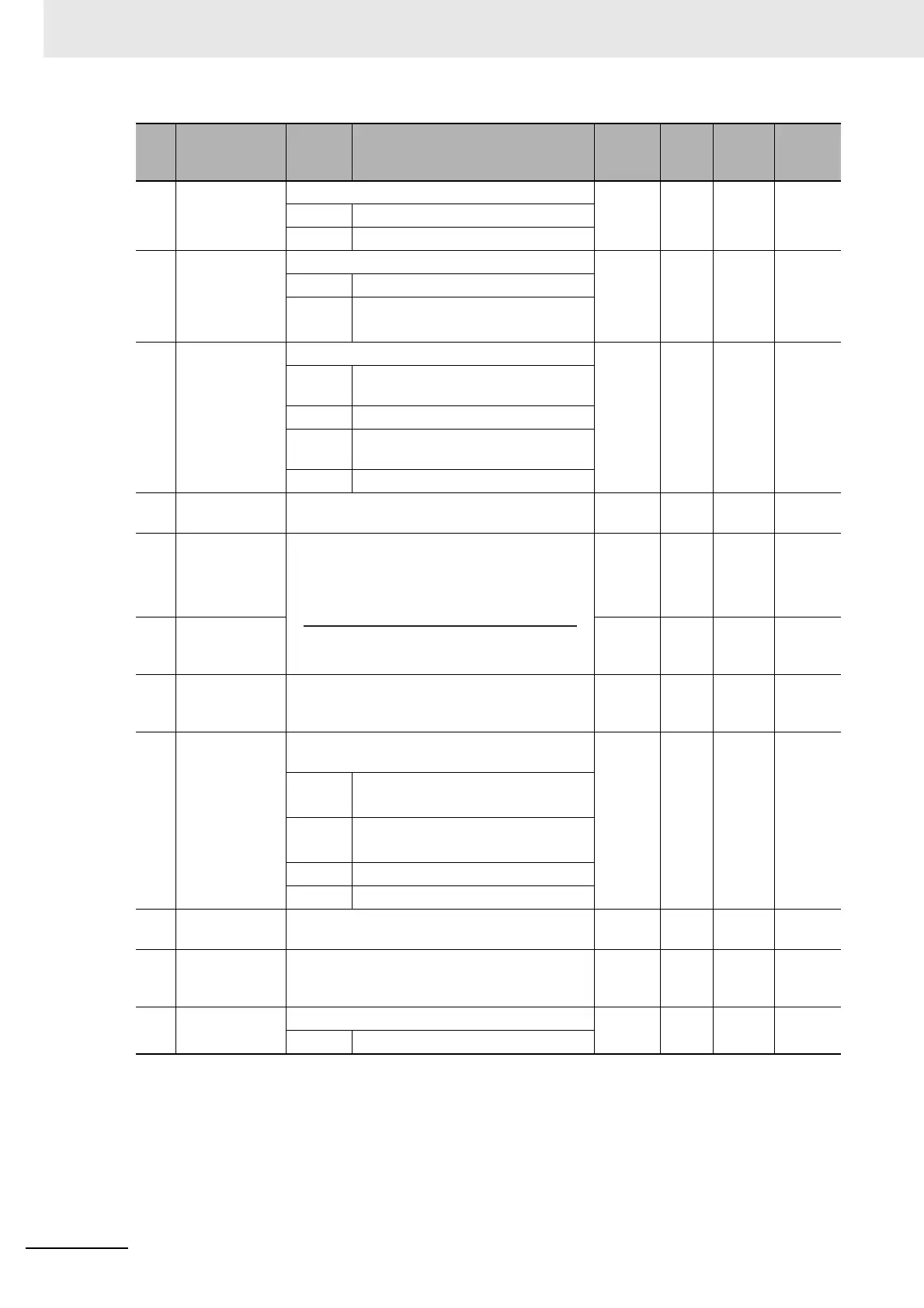

005

Command Pulse

Input Selection

Select the command pulse input mode. 0 – 0 to 1

Required

0 Photocoupler input

1 Input for line driver only

006 Command

Pulse Rotation

Direction

Switching

Selection

Select the command pulse count direction. 0 – 0 to 1

Required

0 Forward direction

1 Reverse direction

007 Command

Pulse Mode

Selection

Set the command pulse mode. 1 – 0 to 3

Required

0 90° phase difference (A/B) signal

input

1 Forward pulse/Reverse pulse

2 90° phase difference (A/B) signal

input

3 Feed pulse/Forward or reverse signal

008 Electronic Gear

Integer Setting

Set the number of command pulses per motor

rotation.

10,000

Pulse

0 to 2

20

Required

009 Electronic Gear

Ratio

Numerator 1

Set the electronic gear ratio.

If Pn009 = 0, the encoder resolution is set in the

numerator.

0–

0 to 2

30

–

010 Electronic Gear

Ratio

Denominator

10,000 –

1 to 2

30

–

011 Encoder

Dividing

Numerator

Set the number of output pulses per motor

rotation for phases A and B.

2,500 P/r 1 to

262,144

Required

012 Encoder Output

Direction

Switching

Selection

Select the combination of the phase-B logic and

the output source for pulse regeneration output.

0 – 0 to 1

Required

0 Phase-B logic: Not reversed

Output source: Encoder

1 Phase-B logic: Reversed

Output source: Encoder

2 Reserved (Do not set.)

3 Reserved (Do not set.)

013 No. 1 Torque

Limit

Set the first output torque limit of the

Servomotor.

500 % 0 to

500

–

014 Error Counter

Overflow Level

Set the range of the error counter overflow level.

Detection of error counter overflow level error is

disabled if the set value is 0.

10,0000

Command

unit

0 to 2

27

–

015 Reserved Do not set. 1 – 1 –

1 Use as incremental encoder.

Pn

No.

Name Setting Description

Default

setting

Unit

Setting

range

Cycle the

power

supply

Electronic Gear Ratio Denominator (Pn010)

Electronic Gear Ratio Numerator 1 (Pn009)

Loading...

Loading...