07-02-12-02-EN-V1215.doc / Type: 638

11

1 General Information

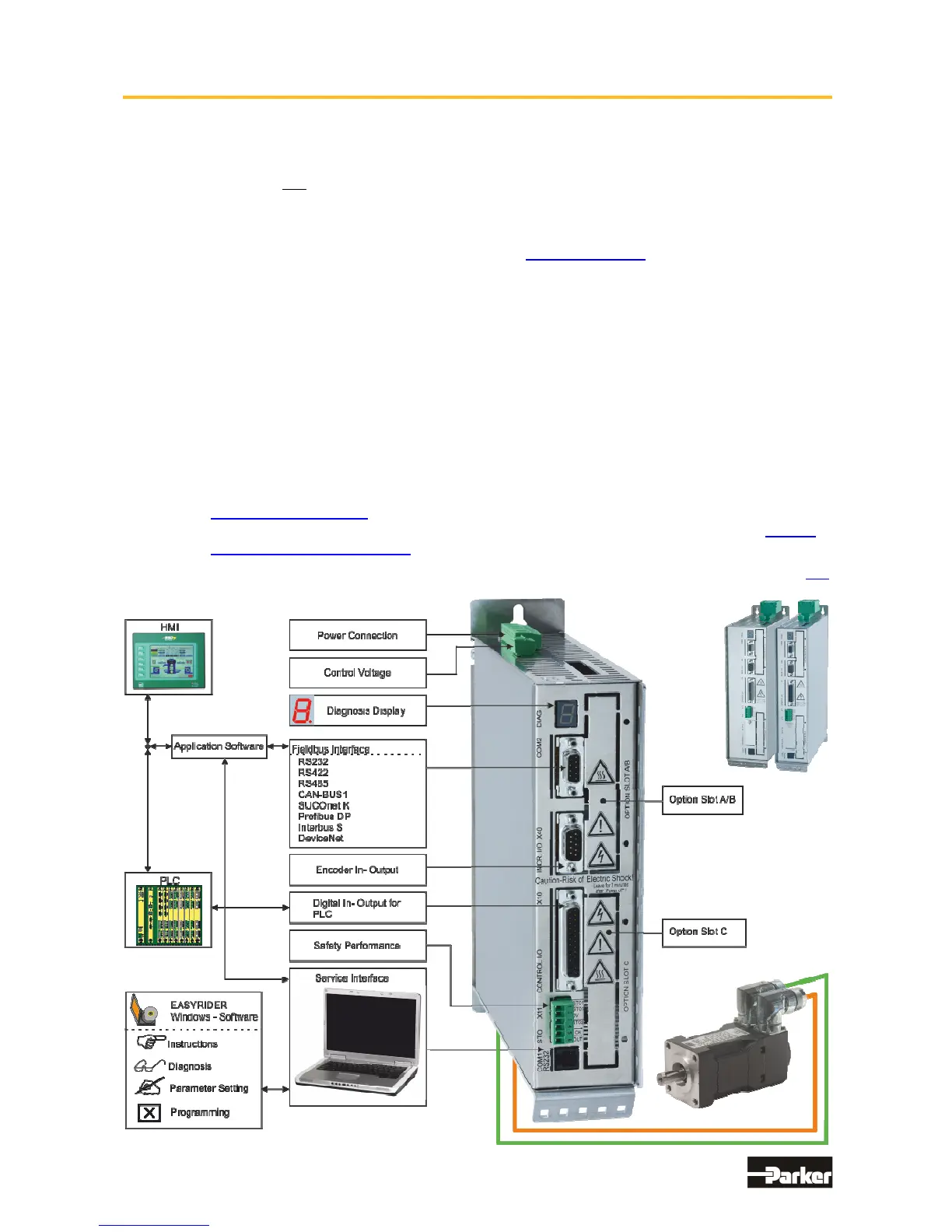

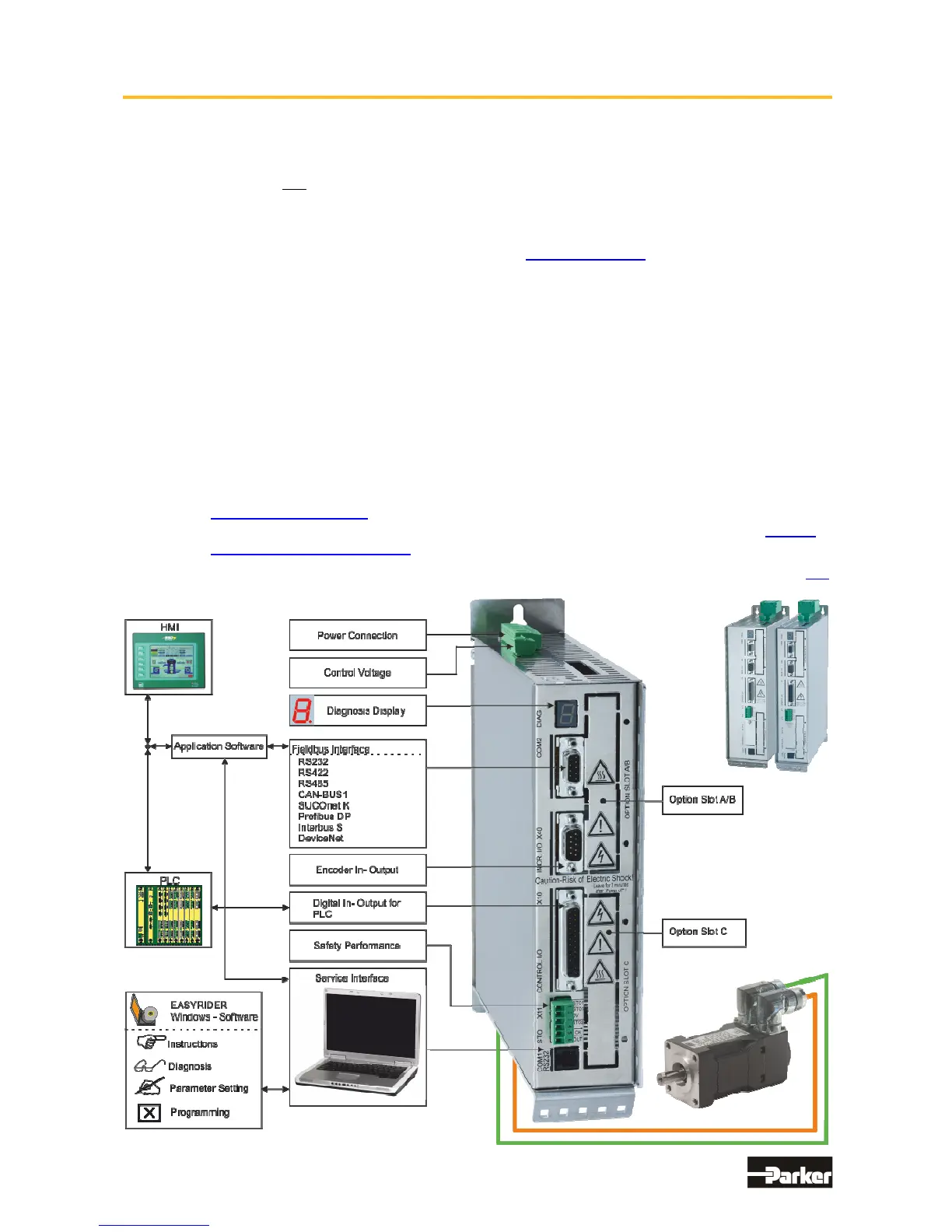

1.1 System Description

● Special Features of the 638 Servo Drive

• The digital 638 servo drive provides for the electrical connection, rotational speed and position

control of the AC servo motor.

• All of the functions and system controls are digitally regulated, employing a

sampling rate of 105µs.

• The 638 servo drive supports the safety function ”Safe Torque Off“, STO, providing for a

definitive system shut-down, for protection against an unanticipated start-up, in accordance with

the requirements as stated in EN 13489-1, Category 3, Performance Level d and EN1037.

• The feedback generated from the braking energy is dissipated through the employment of

internal ballast resistance and when required through the employment of additional external

ballast resistance.

• The AC supply voltage can be directly connected or it can be connected through a transformer,

as required. (Important: only operated on networks which are grounded at the centre point

(TN networks)

• The servo drive additionally requires a 24 V DC control supply voltage connection.

• The built-in internal EMC filter corresponds to the requirements regarding susceptibility to

interference for industrial systems as described in EN50081-1.

• By employing various option modules, through 2 additional plug-in receptacles, it is possible

to increase the potential connections to the field bus system and/or the input/output terminals.

• Various motor feedback loop systems can be supported by employing the flexible

feedback module X300.

• Through the employment of additional 638 drives it is optionally possible to couple the DC link.

• Minimal Housing Dimension is provided through the intelligent compact design of the unit.

● Overview of Standard Digital Communication

Loading...

Loading...