Parker Hannifin S.p.A. Divisione S.B.C. user’s manual TWIN-N and SPD-N

140

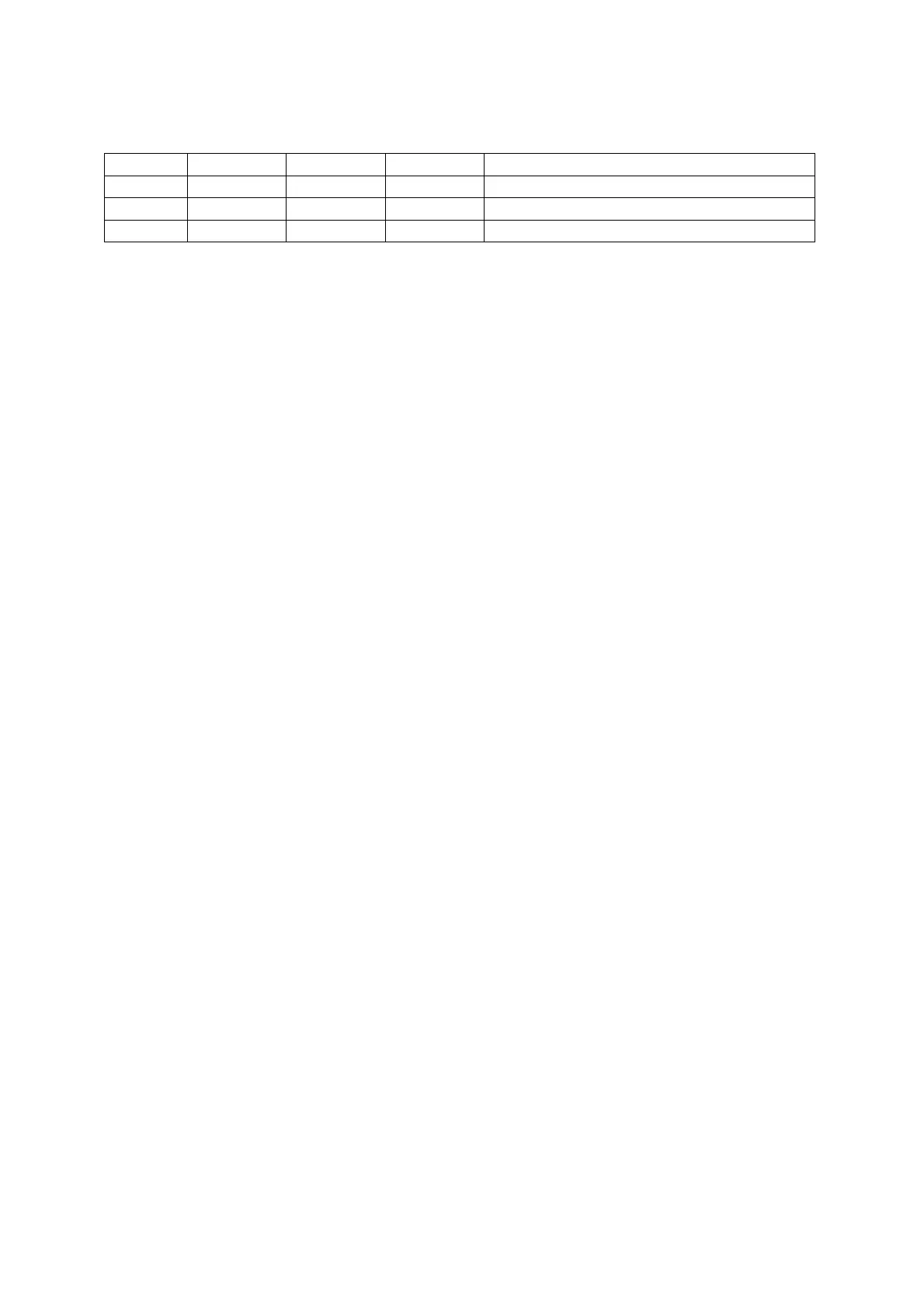

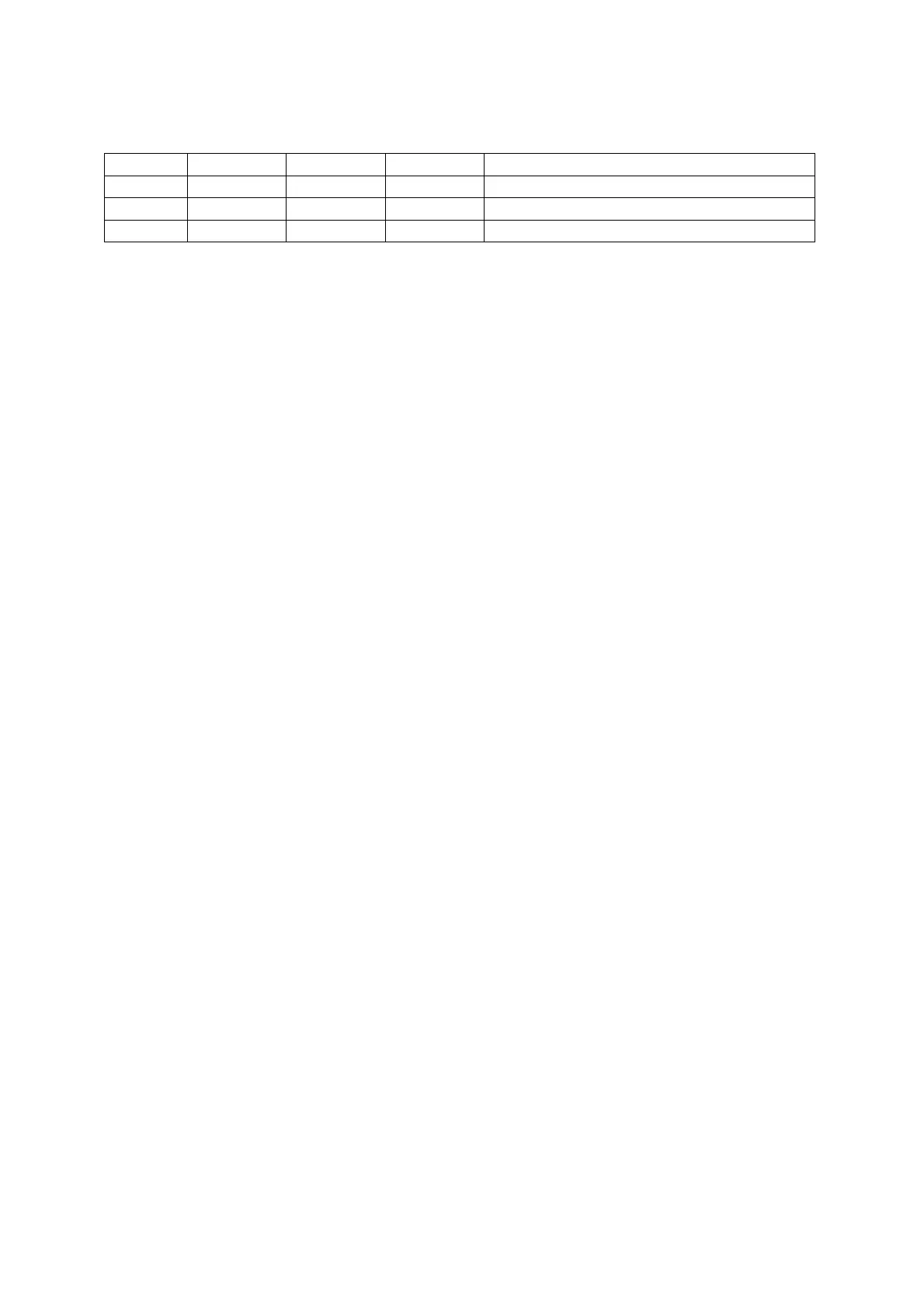

See the next table:

PAR MIN MAX DEF DESCRIPTION

152 -2

31

2

31

CANopen user emgy message

153 -2

31

2

31

CANopen user emgy message

161 -2

31

2

31

CANopen user emgy message

b39.14 CANopen Node Guard watchdog.

Loading...

Loading...