Menu Descriptions

34

5

CONTROL CHART PARAMETERS: A control chart

is a graphical tool which can assist the user in

determining whether or not their process is in

control. Many standard methods will dictate that a

reference sample be measured periodically and the

results plotted on a graph. Limits for acceptable

values are defined and the process is assumed

to be in control as long as the results stay within

these limits. Since results are expected to scat-

ter with a normal distribution within established

limits, systematic trends or patterns in the data

plots may also be an early warning of problems.

CHARTED VALUE: Toggles the charted value

between the HOC Standard (Heat Of Combus-

tion of Standard) and Energy Equivalent.

PROCESS SIGMA: In relation to calorimetry,

sigma is used as the classification of the instru-

ment. The higher the process sigma the higher

the limits for acceptable values for precision

control.

Note: The 6400 is a 0.1 Process Sigma calorimeter.

TEMP. RISE HIGH WARNING: Sets a limit for

the temperature rise during a test. If the tem-

perature rise exceeds the limit the user will be

warned.

TEMP. RISE LOW WARNING: Sets a lower limit

warning for the temperature rise during a test.

If the temperature rise is lower than this setting

the user will be warned.

USE BOMB: Displays the ID of the bomb currently

being used in the Calorimeter and toggles through

the four possible bomb numbers.

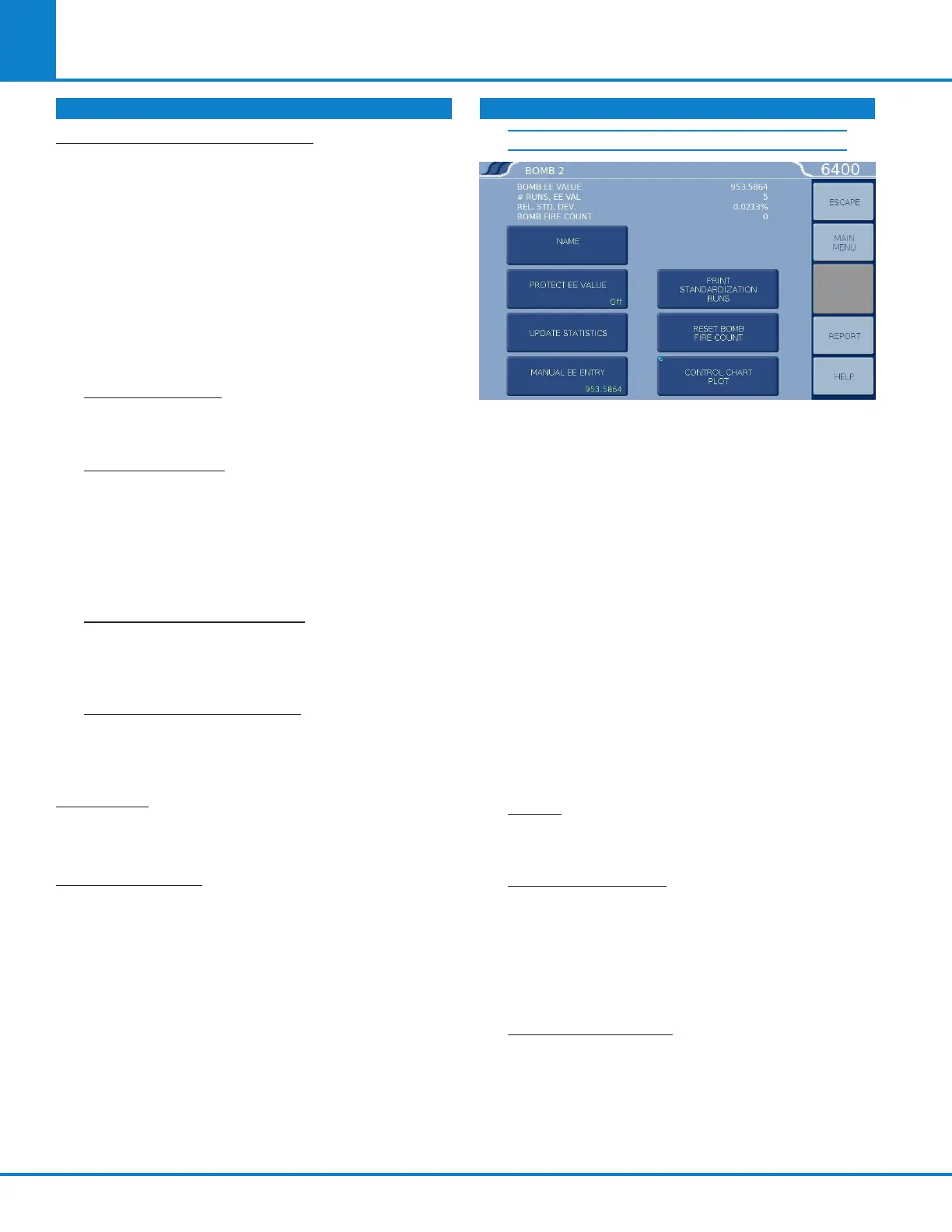

BOMB 1 - BOMB 4: Leads to sub-menu, Bomb 1 -

Bomb 4. Displays standardization information for

bomb and bucket combinations. While only one

bomb and bucket is installed in the calorimeter at

a time, a spare may be used for servicing and for

more rapid turn-around. The respective EE values

for each bomb can be stored in memory.

Note: For rapid turn around between tests, the user

may wish to use an extra head. Each head should

be assigned a bomb ID. On the Data Entry Controls

Menu, set the Prompt for Bomb ID to “ON”.

BOMB 1

The following four values are displayed for the

Bomb # shown in the title on top of the screen.

» BOMB EE VALUE. Displays the calculated

EE value.

» # RUNS, EE VAL. Displays how many runs

have been used to determine the EE value.

» REL. STD. DEV. Displays the relative stan-

dard deviation for the series of tests used to

determine the current EE value in percent

of the EE value.

» BOMB FIRE COUNT. Displays the current

bomb firing count or the number of times

the bomb has been fired since it was last ser-

viced. When this count matches the limit set

by Bomb Service Interval (on the Calibration

Data and Controls screen), the user will be

informed that the bomb is ready for service.

NAME: Enables the operator to assign a

unique alpha-numeric label for the bomb ID.

The ID can be up to 8 characters.

PROTECT EE VALUE: Toggles between OFF

and ON. When set to OFF, the 6400 automati-

cally updates the EE value as new tests are run.

When set to ON, it keeps the EE value protect-

ed, whether it has been revised manually via

the Manual EE Entry key or calculated by the

instrument.

UPDATE STATISTICS: If the Protect EE Value is

set to OFF, pressing this key will cause the EE

Value for this Calorimeter to be updated using

all standardization runs currently in memory to

the limit established in the Calibration Data and

Controls menu. If the Protect EE value is set to

ON, this key is not functional.

CALIBRATION DATA AND CONTROLS (CONTINUED) CALIBRATION DATA AND CONTROLS (CONTINUED)

Loading...

Loading...