Mounted to the spindle assembly is a ring with equally spaced notches and one additional

notch spaced midway between two of the other notches; this is referred to as the Phase

Lock Ring and is used for sectoring

and

speed control.

In

dual disk models, a fixed disk is mounted to the spindle assembly; it is referred to

as

the lower disk but is not removable

in

the same manner

as

the cartridge. The second

disk is contained within the removable cartridge and is driven by a magnetic clutch which

is located

on

top

of

the spindle assembly. A precision ground cone

on

the

end

of

the

spindle suitably locates the hub

of

the disk which is mounted in the cartridge. Rotary

motion is imparted to both disks simultaneously.

The

blower is rotated while the drive motor is running and the disk is spinning. Air flow

from the blower travels through the disk area and purges the air of any contaminants in

this

area.

Air is drawn

in

at the lower front part of the front

bezel

and passes through a high

efficiency absolute filter located in the lower front portion of the base assembly.

Air is ducted to the squirrel cage blower and thence to the area below the fixed disk.

Suitable vanes

on

the spindle provide additional pumping action to cause air

to

flow into

the

area

of the upper disk. Air is exhausted at the rear

of

the disk drive.

As

a function of

exhausting the air, the electronics package

Is provided with Suitable cooling.

Additional cooling is provided through convection cooling of the heatsink assemblies

mounted at the rear of the base assembly. Power transistors mounted on these heatsink

assemblies are used in the power supply regulators

and

the positioner power amplifiers.

The base assembly provides mounting attachment pOints for the rack mounting slides,

switch brackets, front bezel,

and

the supporting structure for the printed circuit boards

and dust cover.

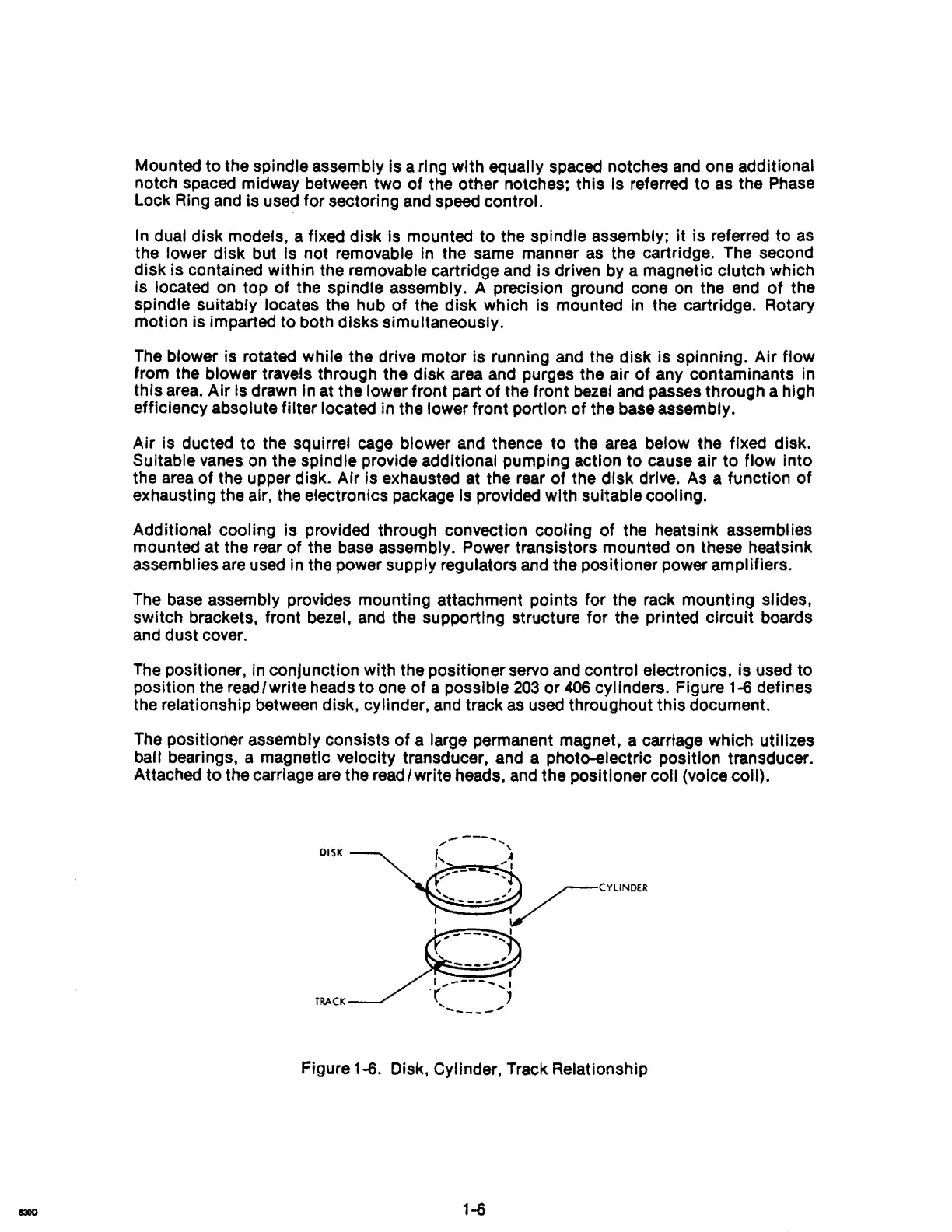

The

pOSitioner, in conjunction with the positioner servo and control electroniCS, is used to

position the read/write heads

to

one of a possible

203

or

406

cylinders. Figure 1-6 defines

the relationship between disk, cylinder, and track

as

used throughout this document.

The positioner assembly consists

of

a large permanent magnet, a carriage which utilizes

ball bearings, a magnetic velocity transducer, and a photo-electric position transducer.

Attached to the carriage

are

the read/write heads,

and

the pOSitioner coil (voice coli).

Figure 1-6. Disk, Cylinder, Track Relationship

1-6

Loading...

Loading...