The positioner servo electronics comprise a major functional block. As the disk rotates

at

a fixed speed, and the recording heads are flown over the disk surface, the positioner is

controlled

In

both the velocity and position modes. The positioner moves

to

the correct

address under control

of

the pOSitioner servo control electronics. Data are then written on

the desired surface by selecting the corresponding

head

through the

head

select network.

The

read

/write electronics are subdivided into three functional blocks consisting of the

head

select network, the write electronics, and the read channel. Write data causes write

current to

be

switched according to the pulse train on the

WRITE

DATA SIGNAL line.

The

storage

surfac~

will then

be

magnetized accordingly.

During retrieval

of

the stored data, the corresponding head

is

again selected by the

head

select network and the signal obtained from the read/write head Is processed

by

the

read

channel Into separate

READ

DATA and

READ

CLOCK Signals for transmission via the

interface. The particular segment

of

the disk which Is pasSing under the read/write

head

is

specified by the sector pulse and sector count lines from the sector electronics.

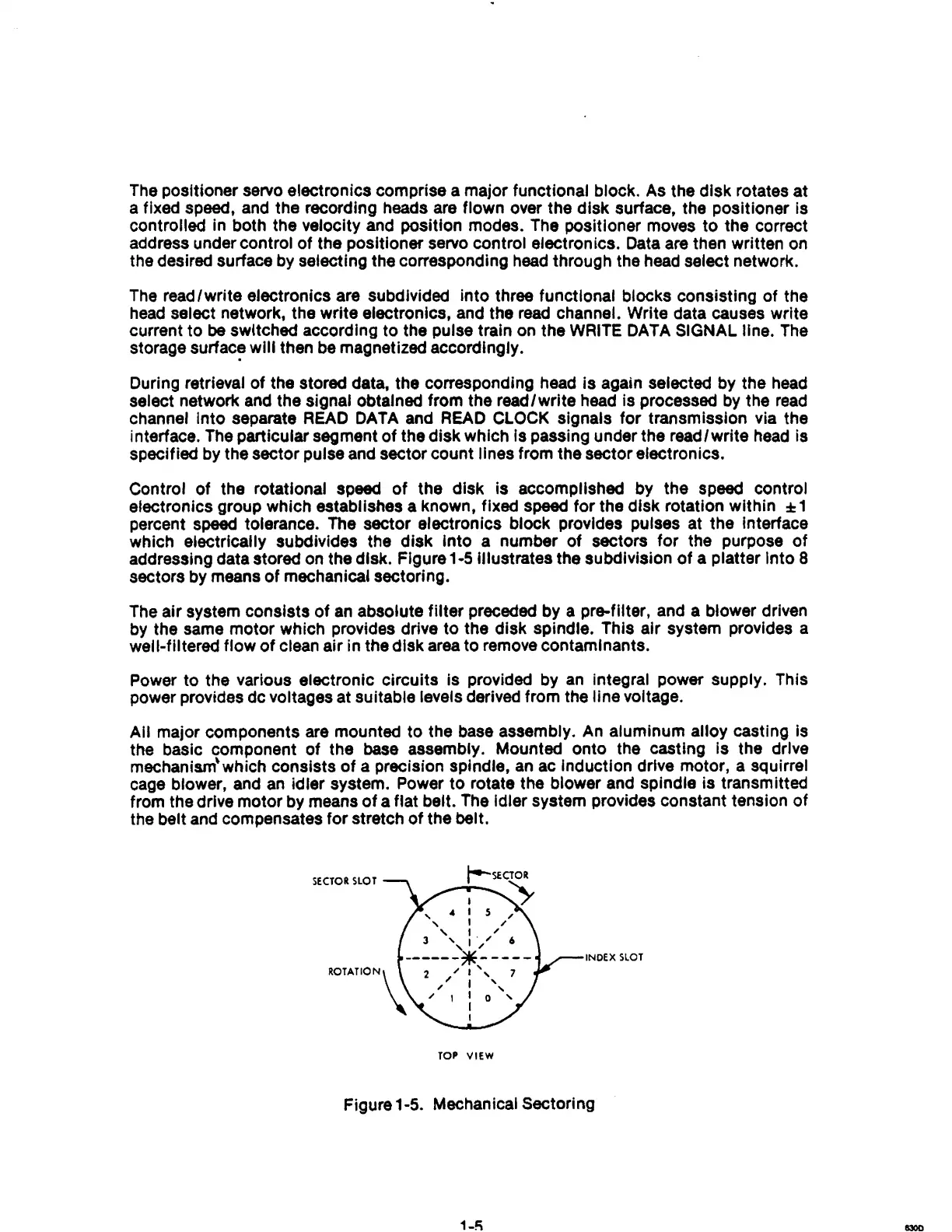

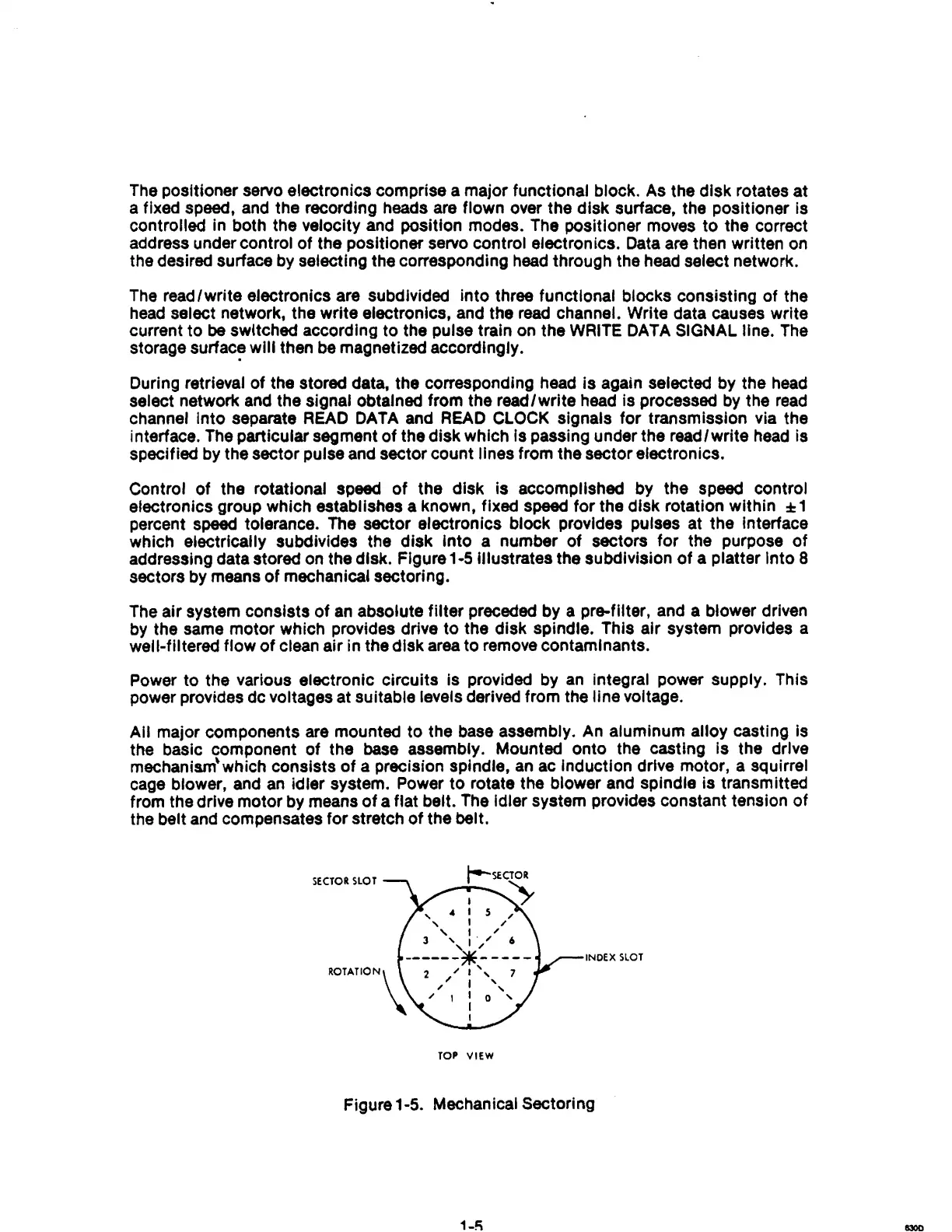

Control of the rotational speed

of

the disk is accomplished by the speed control

electronics group which establishes a known, fixed speed

for

the disk rotation within ± 1

percent

speed

tolerance. The sector electronics block provides pulses at the Interface

which electrically subdivides the disk

Into a number

of

sectors for the purpose

of

addressing data stored on the disk. Figure 1·5 Illustrates the subdiviSion

of

a platter Into 8

sectors by means

of

mechanical sectoring.

The air system consists

of

an

absolute filter preceded by a pre.fllter, and a blower driven

by the same motor which provides drive

to

the disk spindle. This air system provides a

well-filtered flow

of

clean air in the disk area to remove contaminants.

Power to the various electronic circuits

Is provided by

an

integral power supply. This

power provides dc voltages at suitable levels derived from the

line voltage.

All major components are mounted to the base assembly. An aluminum alloy casting

Is

the basic component of the base assembly. Mounted onto the casting is the drive

mechanism'which consists

of

a precision spindle,

an

ac Induction drive motor, a squirrel

cage blower, and

an

idler system. Power

to

rotate the blower and spindle

is

transmitted

from the drive motor by means

of

a flat belt. The Idler system provides constant tension

of

the belt and compensates for stretch

of

the belt.

SECTOR

SLOT

INDEX

SLOT

TOP

VIEW

Figure 1-5. Mechanical Sectoring

1-~

Loading...

Loading...