[II

I

(11

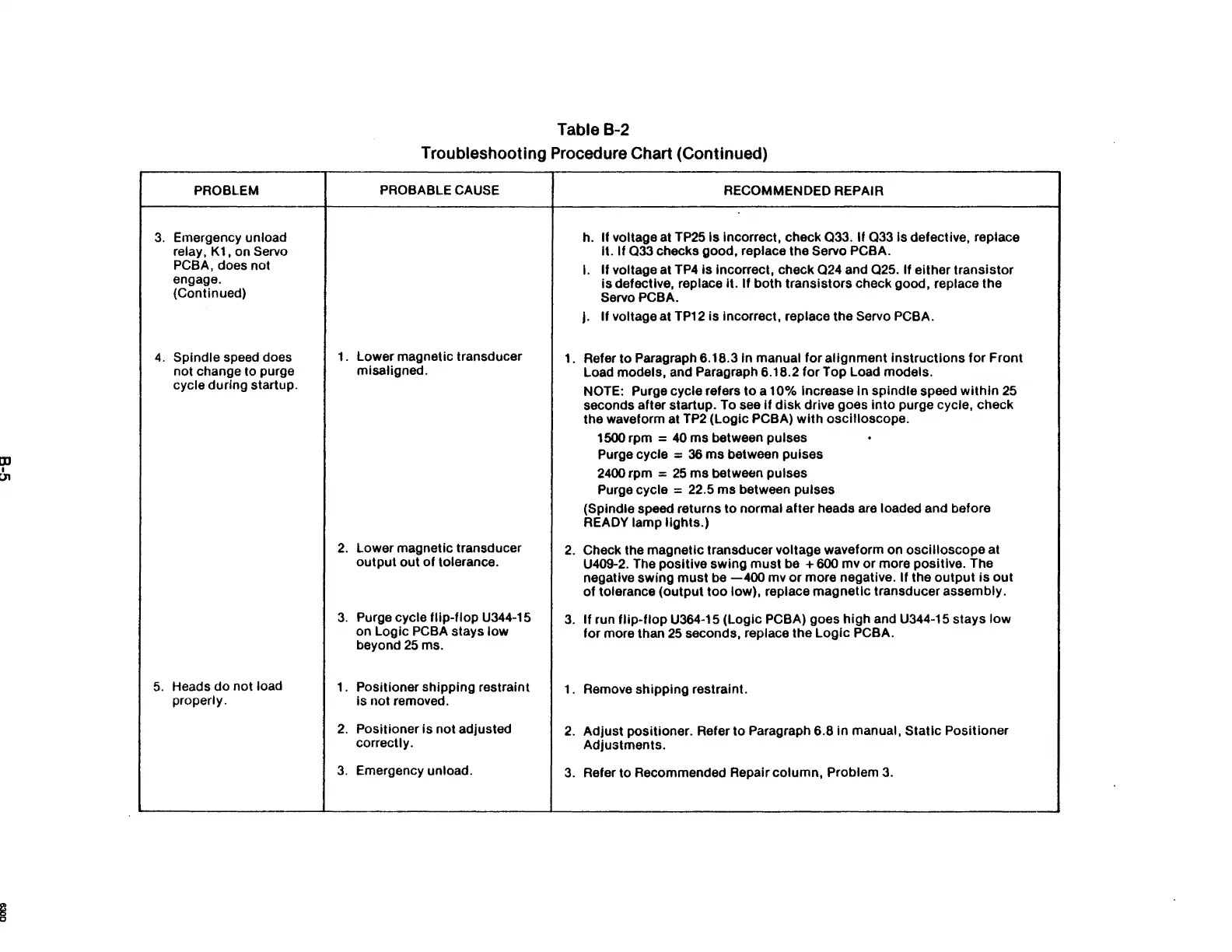

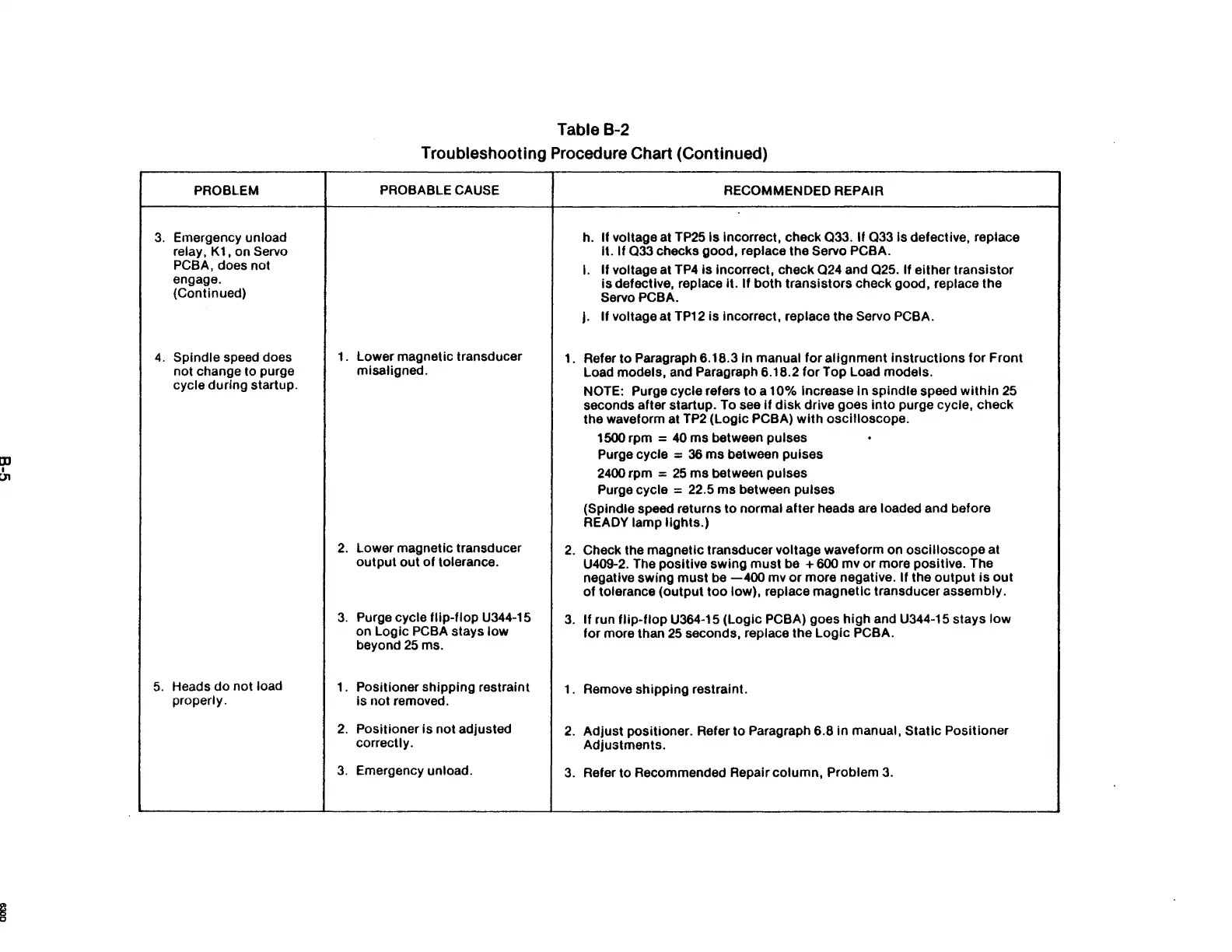

3.

4.

5.

PROBLEM

Emergency unload

relay,

K1, on Servo

PCBA,

does not

engage.

(Continued)

Spindle speed does

not change to purge

cycle during startup.

Heads

do

not load

properly.

1.

2.

3.

1.

2.

3.

Table B-2

Troubleshooting Procedure Chart (Continued)

PROBABLE CAUSE

RECOMMENDED REPAIR

h.

If voltage at TP25 Is incorrect, check

033.

If Q33 is defective, replace

It. If

033

checks good, replace the Servo PCBA.

I.

If

voltage at

TP4

is

incorrect, check

024

and

025.

If either transistor

is

defective, replace it. If both transistors check good, replace the

ServoPCBA.

j.

If

voltage at TP12 is incorrect, replace the Servo PCBA.

Lower magnetic transducer

1.

Refer

to

Paragraph 6.18.3 In manual

for

alignment

instructions

for

Front

misaligned.

Load models, and Paragraph 6.18.2

for

Top Load models.

NOTE: Purge cycle refers

to

a 10% Increase In spindle speed

within

25

seconds after startup. To see

if

disk

drive goes

into

purge cycle, check

the waveform at

TP2

(Logic PCBA)

with

oscilloscope.

1500 rpm

=

40

ms between pulses

.

Purge cycle =

36

ms

between pulses

2400 rpm =

25

ms

between pulses

Purge cycle

= 22.5 ms between pulses

(Spindle speed returns

to

normal after heads are loaded and before

READY lamp

lights.)

Lower magnetic transducer

2.

Check the magnetic transducer voltage waveform on oscilloscope at

output

out

of

tolerance.

U409-2. The positive swing

must

be + 600 mv or more positive. The

negative swing

must

be

-400

mv

or

more negative.

If

the

output

is

out

of

tolerance (output

too

low), replace

magnetic

transducer assembly.

Purge cycle

flip-flop

U344-15

3.

If

run

flip-flop

U364-15 (Logic PCBA) goes

high

and U344-15 stays

low

on Logic PCBA stays

low

for more than

25

seconds, replace the

Logic

PCBA.

beyond

25

ms.

Positioner shipping restraint

1. Remove shipping restraint.

is not removed.

Positioner

is

not

adjusted

2.

Adjust

positioner. Refer

to

Paragraph 6.8

in

manual, Static Positioner

correctly.

Adjustments.

Emergency unload.

3.

Refer to Recommended Repair column, Problem

3.

Loading...

Loading...