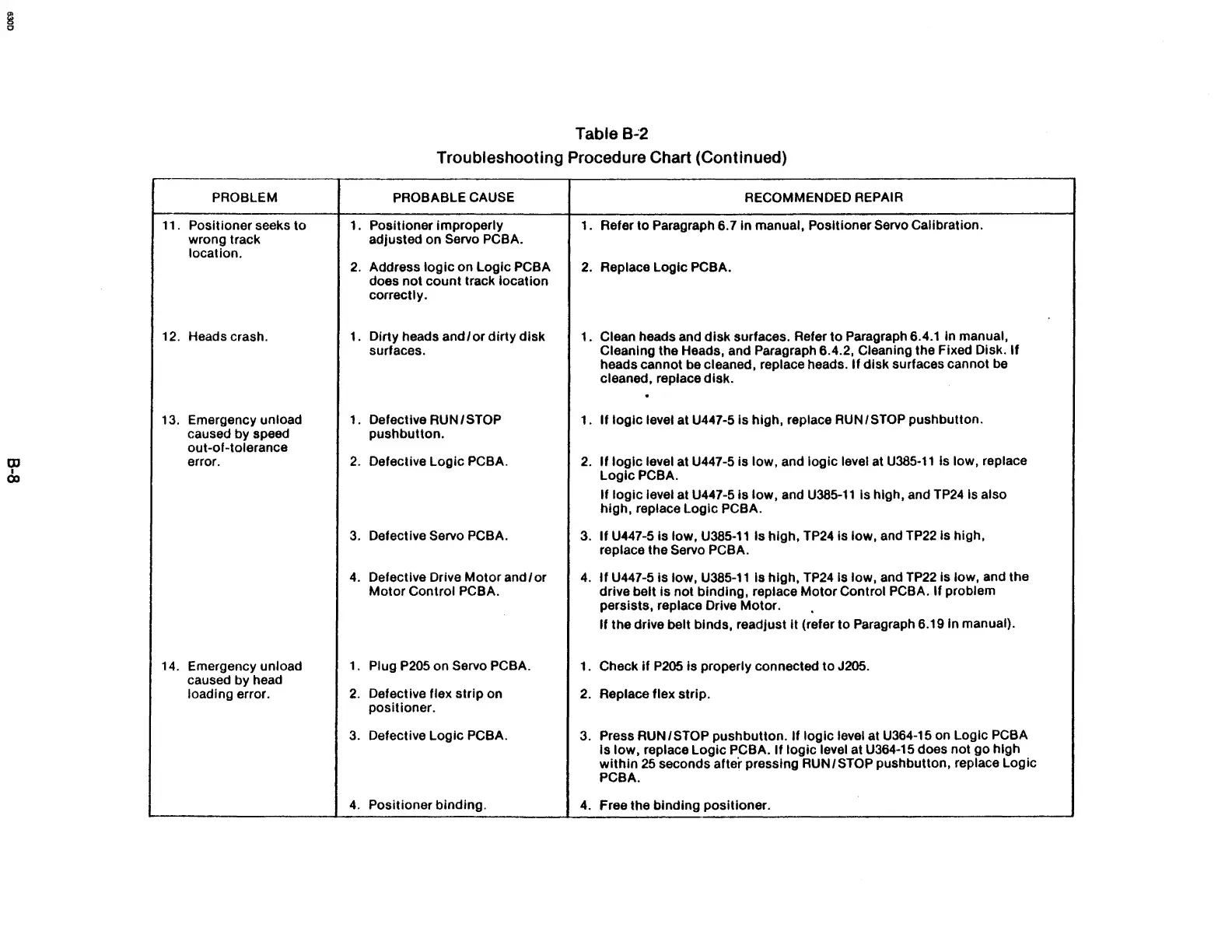

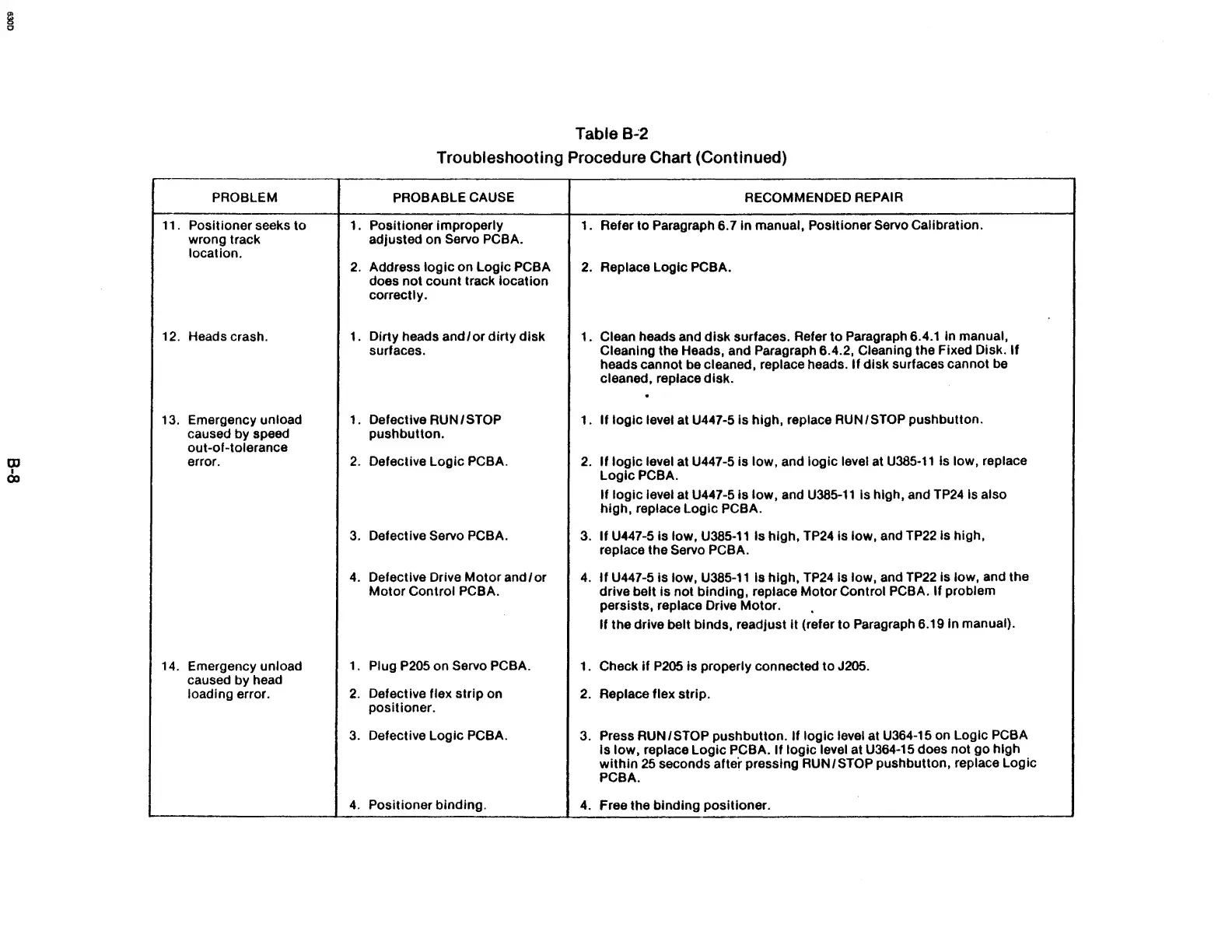

Table

8..:2

Troubleshooting Procedure Chart (Continued)

PROBLEM PROBABLE CAUSE RECOMMENDED REPAIR

11. Positioner seeks to

1.

Positioner improperly

1.

Refer to Paragraph 6.7 In manual, Positioner Servo Calibration.

wrong track adjusted on Servo

PCBA.

location.

2.

Address

logic

on Logic PCBA

2.

Replace Logic PCBA.

does not count track location

correctly.

12. Heads crash. 1. Dirty heads

and/or

dirty

disk

1.

Clean heads and disk surfaces. Refer

to

Paragraph 6.4.1

In

manual,

surfaces. Cleaning the Heads, and

Paragraph 6.4.2, Cleaning the Fixed Disk.

If

heads cannot be cleaned, replace heads.

If

disk surfaces cannot

be

cleaned, replace

disk

.

.

13.

Emergency unload 1.

Defective

RUN

/ STOP

1.

If

logic

level at U447-Sls high, replace RUN/STOP pushbutton.

caused by speed pushbutton.

out-of-tolerance

OJ

error.

2.

Defective Logic PCBA.

2.

If

logic

level at U447-Sls low, and logic level at

U38S-11

Is low, replace

I

00

LoglcPCBA.

If logic level at U447-Sls low, and

U38S-11

Is high, and

TP24

Is

also

high, replace Logic

PCBA.

3.

Defective Servo PCBA.

3.

If

U447-S

Is low,

U38S-11

Is high,

TP24

is low, and TP22 Is high,

replace the Servo

PCBA.

4.

Defective Drive

Motor

and/or

4.

If

U447-S

Is low,

U38S-11

Is high,

TP24

Is low, and

TP22

Is low, and the

Motor

Control PCBA.

drive belt

is

not binding, replace

Motor

Control PCBA.

If

problem

persists, replace Drive Motor.

If the drive belt binds, readjust

it

(refer

to

Paragraph 6.19 In manual).

14.

Emergency unload

1.

Plug P205 on Servo PCBA.

1.

Check

if

P205

Is properly connected to J205.

caused by head

loading error.

2.

Defective flex strip on

2.

Replace flex strip.

positioner.

3.

Defective Logic PCBA.

3.

Press RUN/STOP pushbutton. If logic level at U364-15 on Logic PCBA

Is

low. replace Logic PCBA.

If

logic level at U364-15 does not go high

within

25

seconds afte'r pressing RUN/STOP pushbutton. replace Logic

PCBA.

4.

Positioner binding.

4. Free the binding positioner.

Loading...

Loading...