3) Adjust: Dislodge the linkage

of

the 0-ESO gears,

or replace

0-ESO

with different gear

and

dowel position

s.

(4

types, same part numbers)_,.

Adjust winding looseness

and

roughness by replacing with typ

es

with different diameters.

- Diameter: O-E80-00A. (no

sign)>

-OOB (one mark-off lin

e)>

-OOC (two marks)

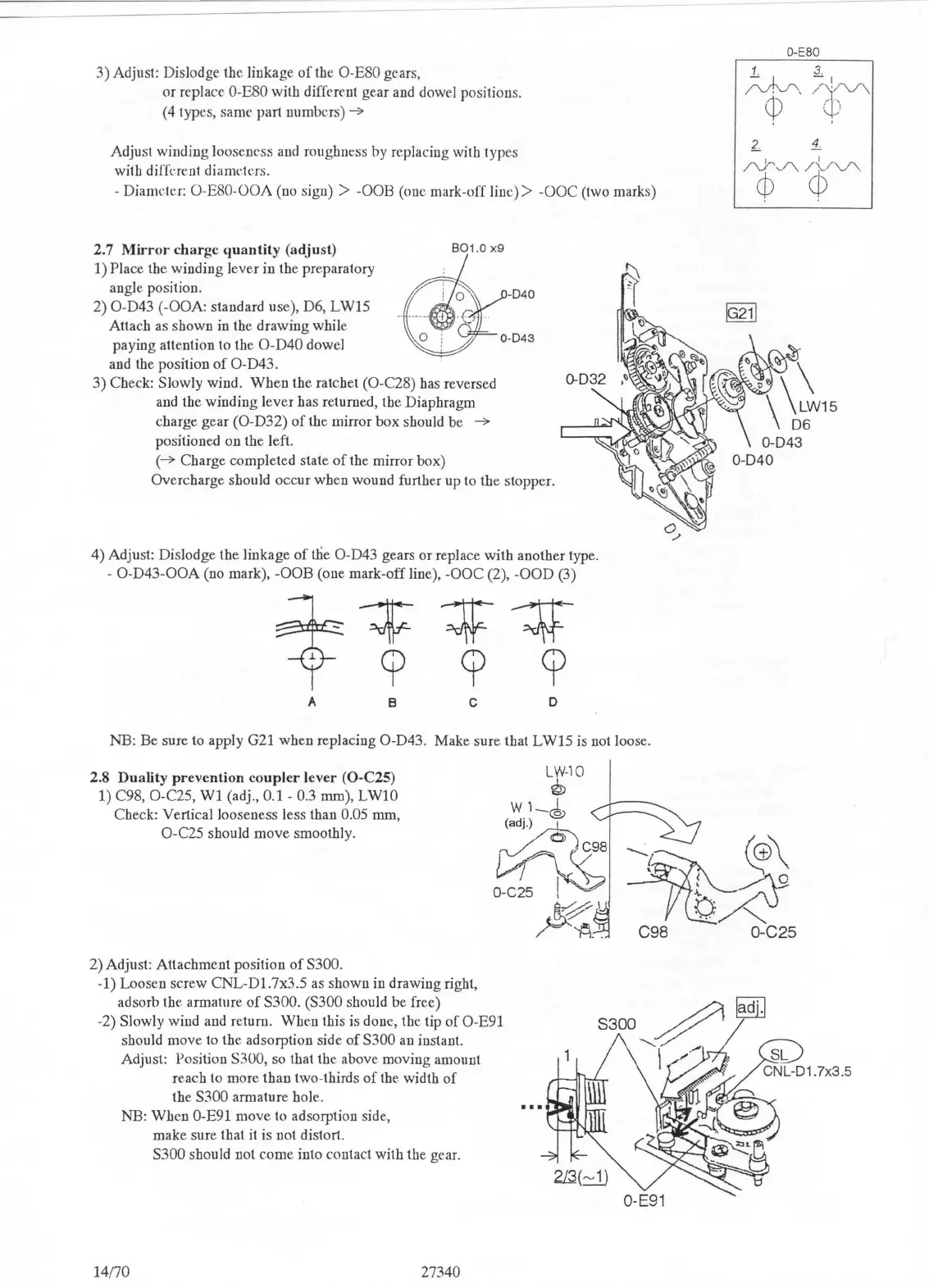

2.7

Mirror

charge

quantity

(adjust)

801.0

x9

1) Place

th

e winding lever in the preparatory

angle position.

2)

O-D43 (-OOA: standard use), D6, LW15

Attach

as

shown

in

the drawing while

paying attention lo the

O-D40 dowel

and

the position

of

O-D43.

3) Check: Slowly wind. When the ratchet (O-C28) bas reversed

and

the winding lever has returned, the Diaphragm

charge gear (O-D32)

of

the mirror box should be _,.

positioned on the left.

(-7 Charge completed state

of

the mirror box)

-040

0-

043

Overcharge should occur when wound further up to the stopper.

4) Adjust:

Di

slodge the linkage oft.lie O-D43 gears or replace with another type.

-

O-D43-00A

(no mark), -OOB (one mark-off line), -OOC (2), -OOD (3)

A

8 c

D

NB: Be sure to apply G21 when replacing O-D43. Make sure that LW15 is not loose.

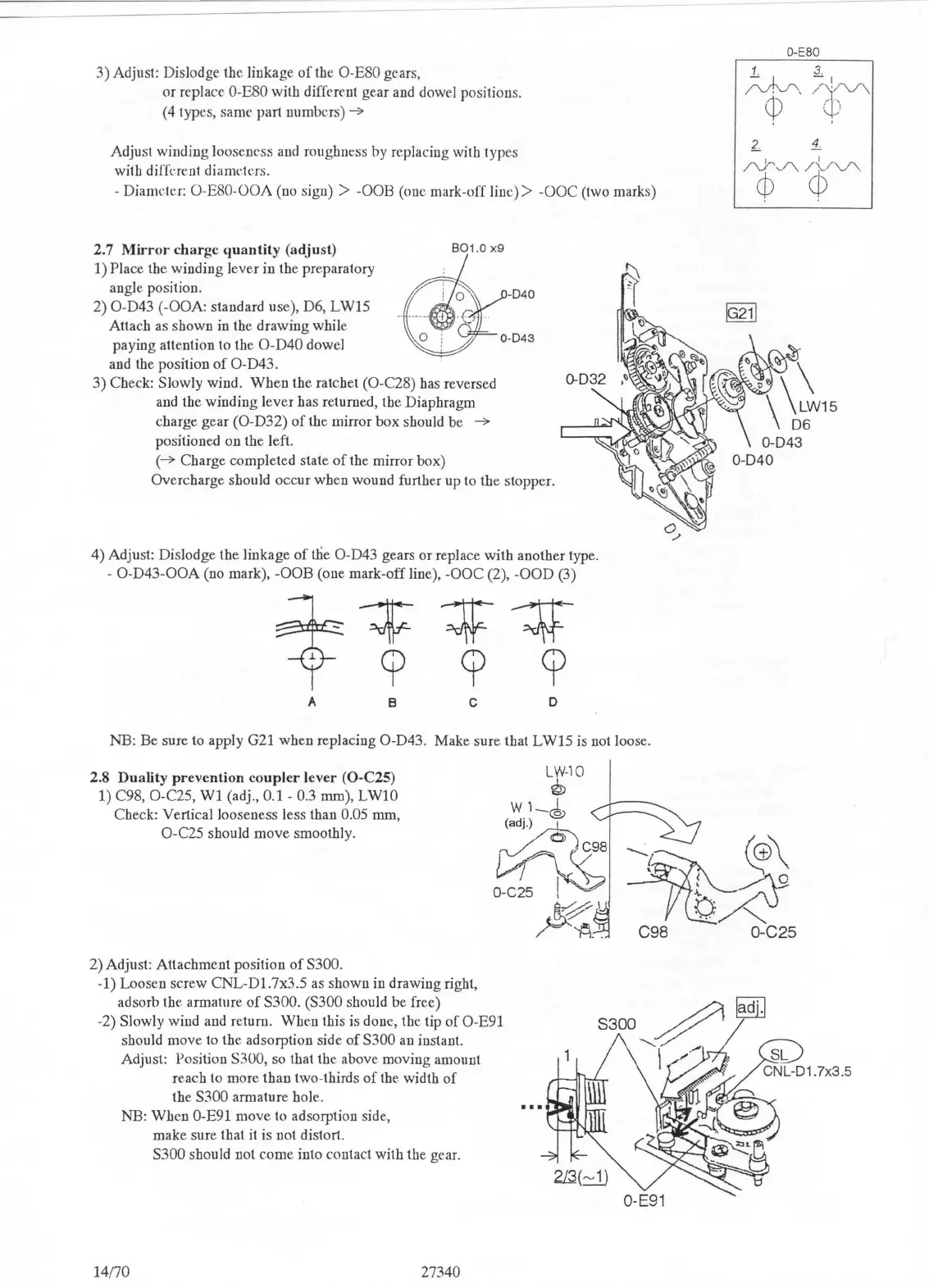

2.8 Duality prevention

coupler

lever (O-C25)

1) C98, O-C25,

Wl

(adj.,

0.1-

0.3 mm), LWlO

Check: Vertical looseness less than

0.05 mm,

O-C25 should move smoothly.

2) Adjust: Attachment position

of

S300.

-1) Loosen screw CNL-Dl.7x3.5

as

shown in drawing right,

adsorb the armature

of

S300. (S300 should be free)

-2) Slowly wind and return. When this is done,

the tip

of

0-E91

should move

to

the adsorption side

of

S300

an

instant.

Adjust: Position

S300, so that the above moving amount

reach to more than two-thirds

of

the width

of

the S300 am1ature bole.

NB: When

O-E91

move

to

adsorption side,

make sure that

it

is

not distort.

S300 should not come into contact with the gear.

14/70 27340

0-EBO

1. 3.

~

'

;~

,"J\

CJ)

ct'

' '

Loading...

Loading...