6.29

ES

magnet

adjustment

1)

Put shutter curtain and mirror base plate

(0

-

Dl)

in

wound up state.

2)

Loosen

1st curtain

Mg

installing screw, lightly push

down

core adsorption surfact·

in

parallel on armature.

adsorption surfac('. aud fasten screw.

Whrn

pushing down the loose par! (approx.

0.1

mm)

of

armature shaft,

the

gaps on the two shoulders of

th('.

armature should be the same.

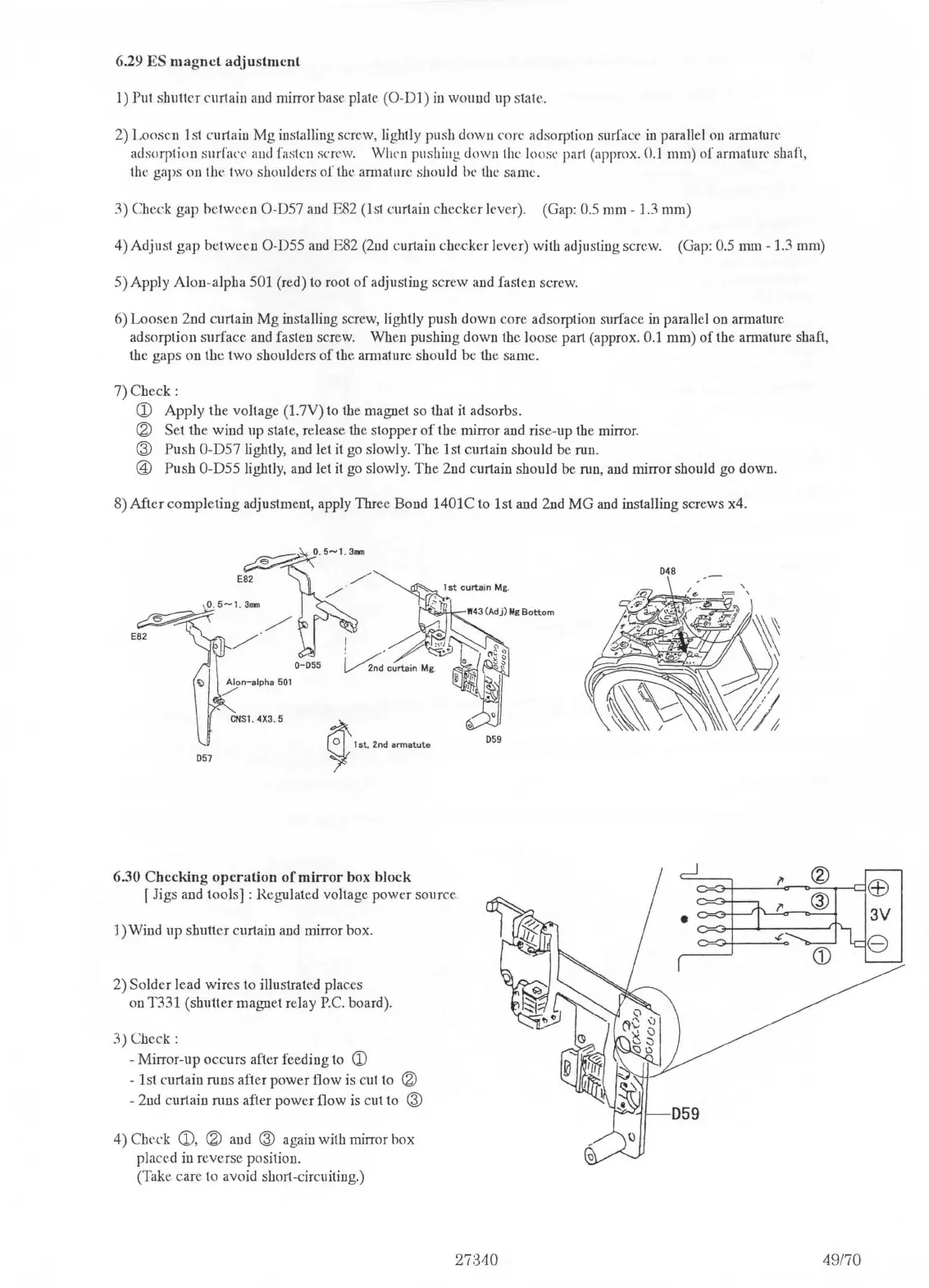

3)

Check gap

between

O-D57 and E82 (1st curtain

checker

lever). (Gap: 0.5 mm - ]

.3

mm)

4)

Adjust

gap

between

O-D55 and E82 (2nd curtain

checker

lever) with adjusting screw. (Gap: 0.5 mm - 1.3 mm)

5)

Apply

Alon-alpha

501 (red) to root

of

adjusting screw and fasten screw.

6)

Loosen

2nd curtain

Mg

installing screw, lightly push

down

core adsorption surface

in

parallel on am1ature

adsorption

surface

and fasten screw. When pushing

down

the loose part (approx. 0.1

mm)

of

the

an11ature

shaft,

the

gaps

on

the

two

shoulders

of

the amiature should

be

the same.

?)Check:

CD

Apply

the

voltage

(l.7V)

to the magnet so that it adsorbs.

® Set

the

wind up state, release the stopper

of

the

mirror and rise-up the mirror.

@

Push

O-D57 lightly, and

Jet

it go slowly.

The

1st curtain should be run.

@)

Push

O-D55 lightly, and let

it

go slowly.

The

2nd curtain should be run, and mirror should go down.

8)

After

completing

adjustment, apply Three Bond 1401C to 1st and 2nd

MG

and

installing screws x4.

059

057

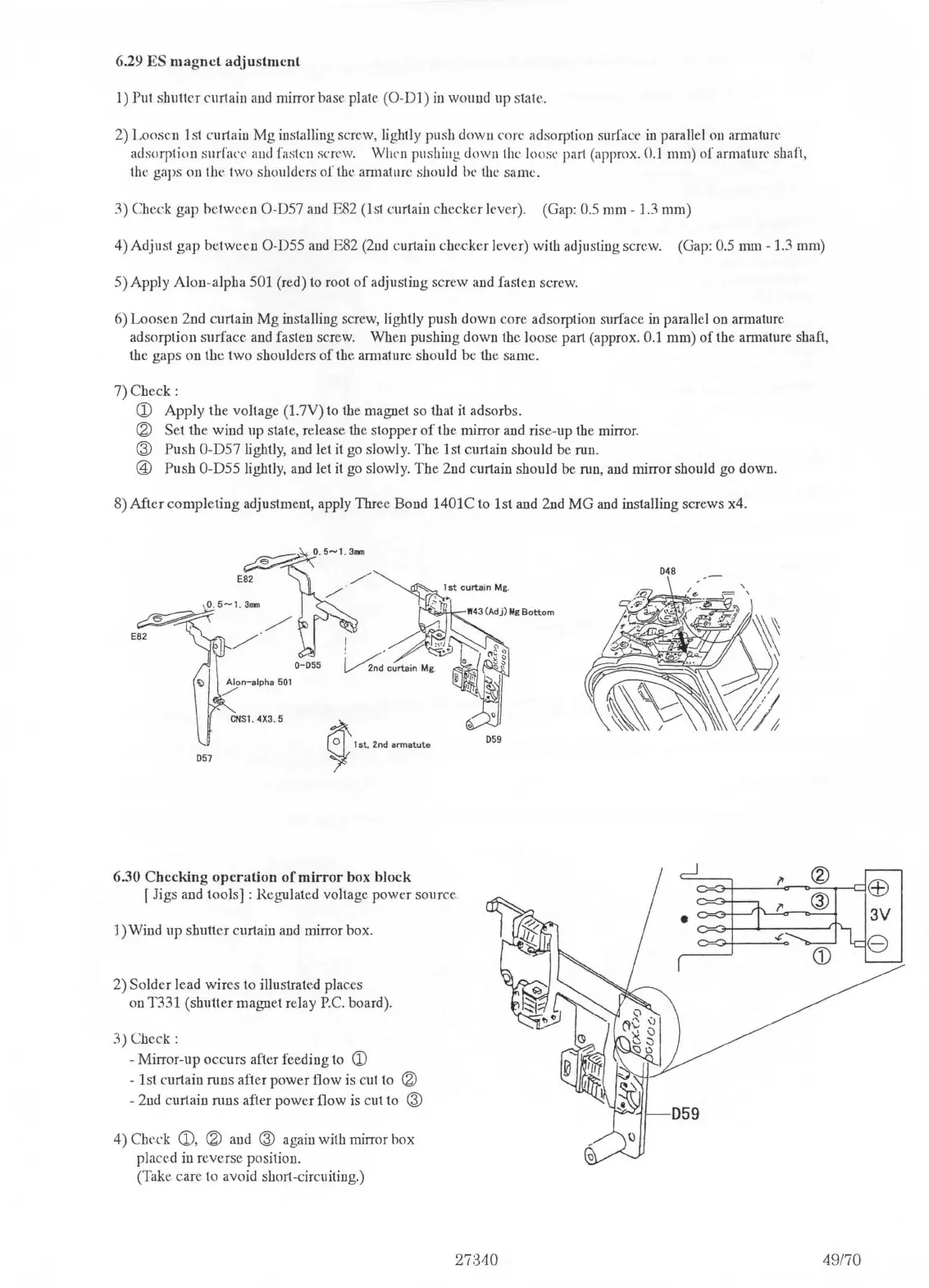

6.30

Checking

operation

of

mirror

box

block

f Jigs and tools] : Rei,rulated voltage

power

source.

1) Wind

up

shutter

curtain and mirror box.

2)

Solder

lead

wires

to illustrated places

on T331 (shutter magnet relay

P.C.

board).

3)Chcck:

- Mirror-up

occurs

after feeding to

CD

-

ls!

curtain runs after

power

flow is cut to ®

- 2nd curtain

nms

after

power

Oow is cut to @

4)

Check

CD,

® and @ again with mirror

box

placed in reverse position.

(Take

care

to avoid shm1-circuiting.)

27:340

048

49170

Loading...

Loading...