83

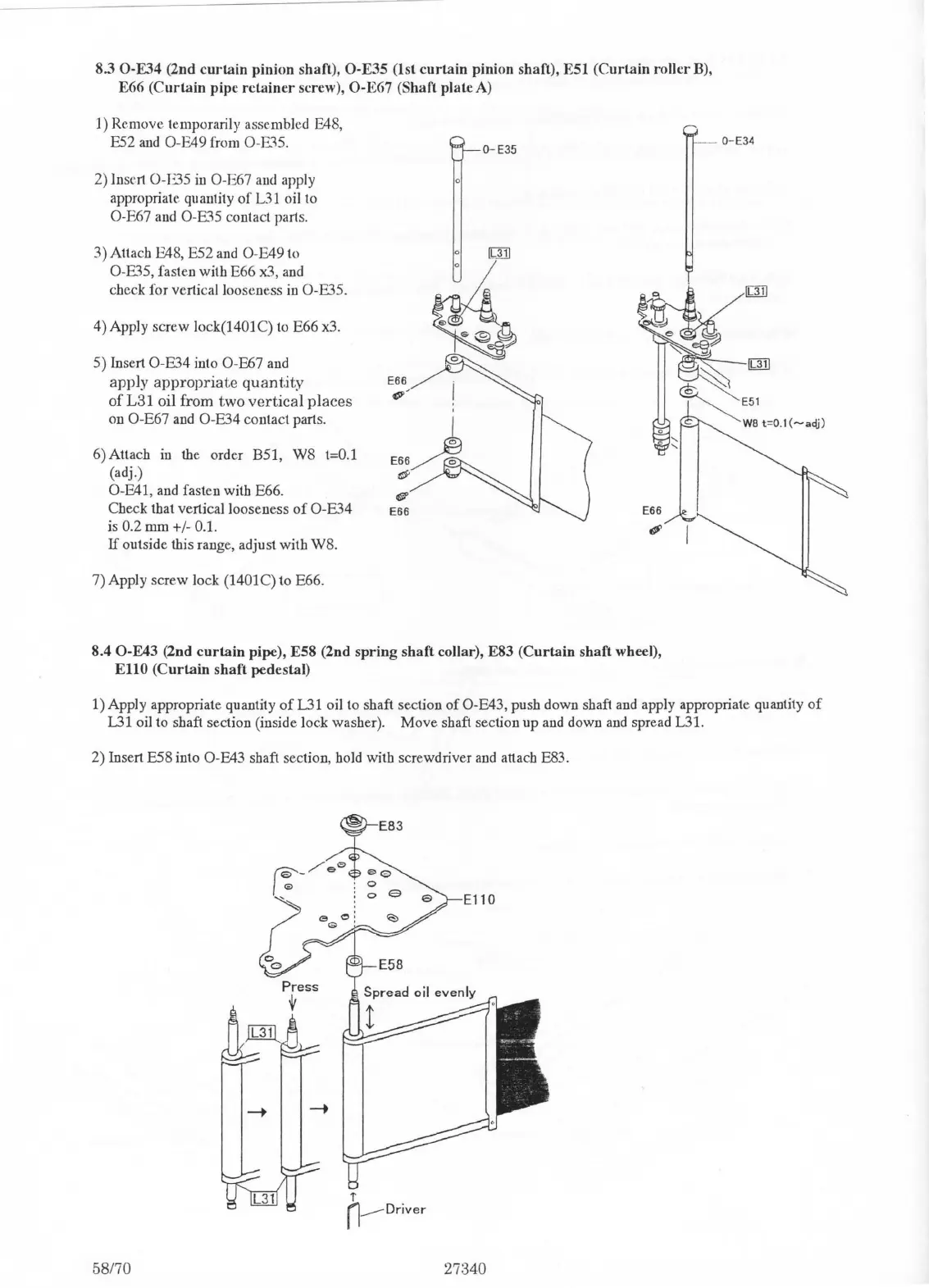

O-E34 (2nd

curtain

pinion shaft), O-E35 (1st

curtain

pinion shaft), E51

(Curtain

roller B),

E66

(Curtain

pipe

retainer

screw), O-E67 (Shaft plate

A)

1) Remove temporarily assembled E48,

E52

and

O-E49 from

O-E.15.

2) lnsert

O-E.35

in

O-E67

and

apply

appropriate quantity

of

L31 oil to

O-E67

and

O-E.15

contact parts.

3) Attach E48, E52

and

O-E49 to

O-E35, fasten with E66 x3,

and

check for vertical looseness in O-E35.

4) Apply screw lock(1401 C)

to

E66

x3

.

5) Insert

O-E34 into O-E67

and

apply appropriate

quantity

of L31 oil from two vertical places

on

O-E67

and

O-E34 contact parts.

6)Attach

in

the order B51, W8 t=0.1

(adj.)

O-E41,

and

fasten with E66.

Check that vertical looseness

of

O-E34

is

0.2

mm+/-

0.1.

If outside this range, adjust with W8.

7) Apply screw lock

(1401C) to E66.

O- E35

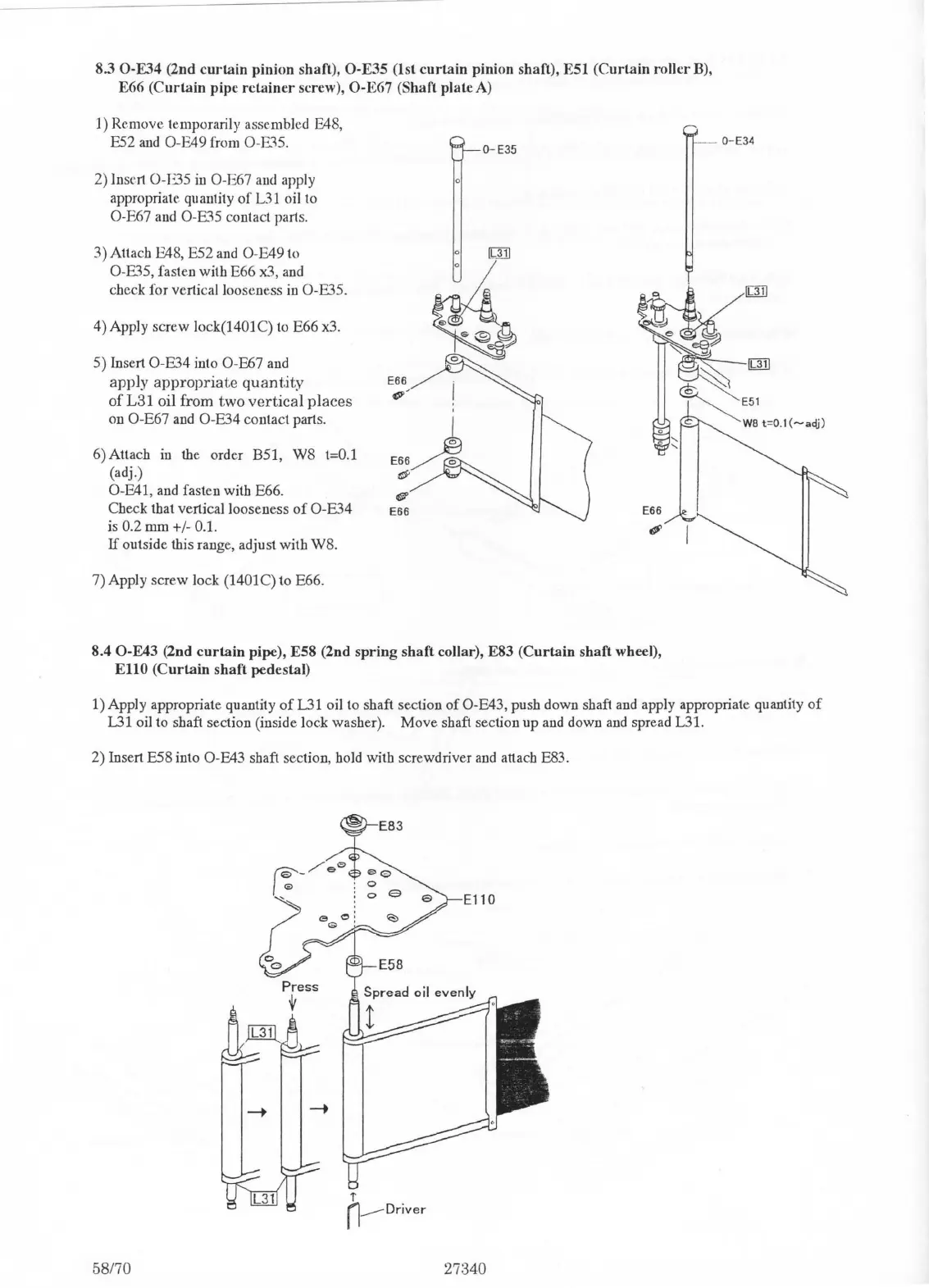

8.4 O-E43 (2nd

curtain

pipe), E58 (2nd

spring

shaft

collar), E83

(Curtain

shaft wheel),

EllO

(Curtain

shaft

pedestal)

-

0-E34

1) Apply appropriate quantity

of

L31 oil to shaft section

of

O-E43, push down shaft

and

apply appropriate quantity

of

L31 oil to shaft section (inside lock washer). Move shaft section up

and

down

and

spread L31.

2) Insert E58 into

O-E43 shaft section, hold with screwdriver

and

attach E83.

58170

<S/-EB3

t

n....---Driver

Loading...

Loading...