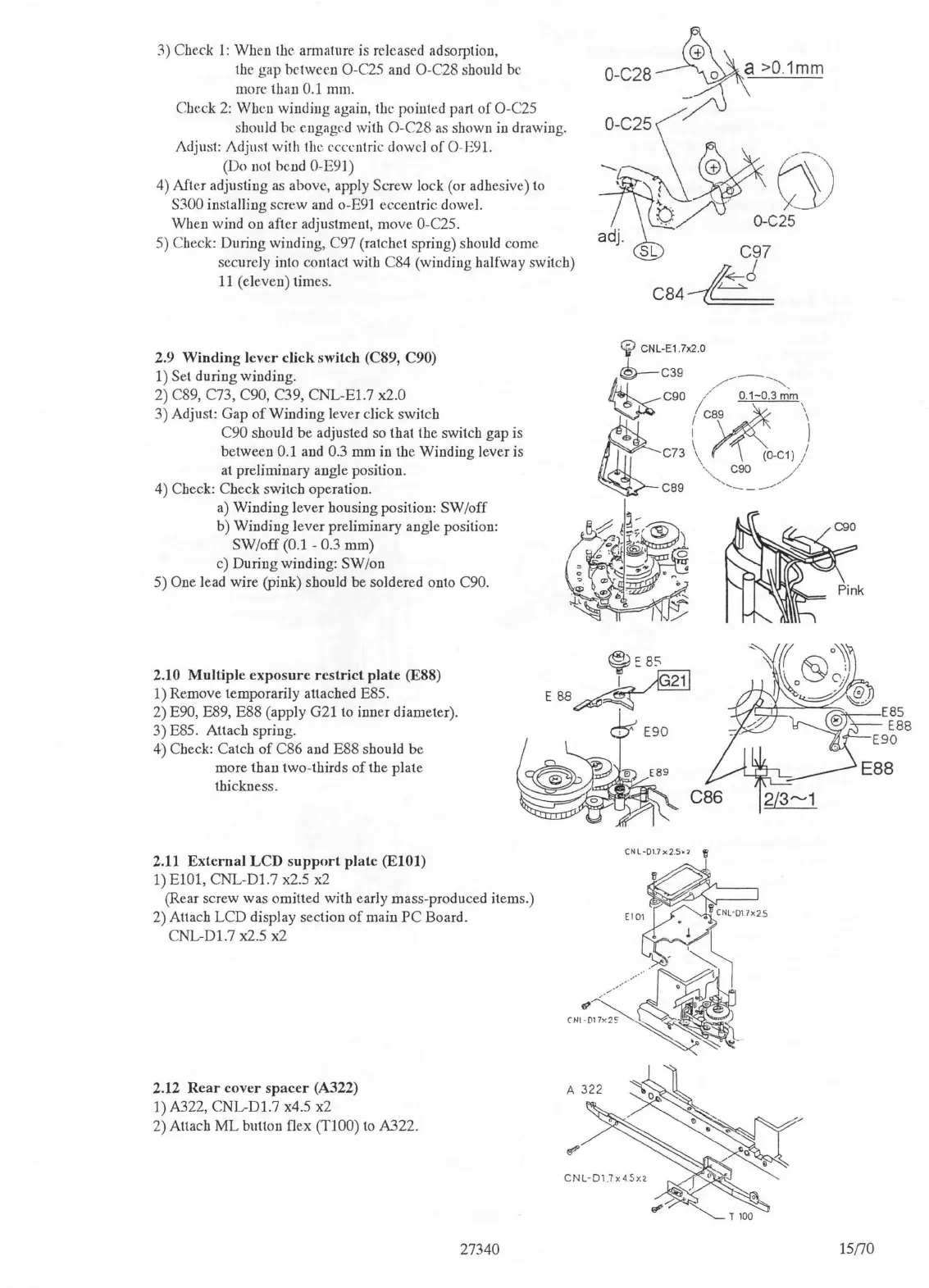

3) Check l : When the armature

is

released adsorption,

the gap

between O-C25

and

O-C28 should be

more

t.han

0.1 mm.

Check

2:

When winding again, the pointed part of O-C25

should he engaged with O-C28

as

shown

in

drawing.

Adjust: Adjust with the eccentric dowel

of

O-E91.

(Do not bend

O-E9

l)

4) After adjusting

as

above, apply Screw lock (or adhesive) to

S300 installing screw

and

o-E91 eccentric dowe

l.

When wind on after adjustment, move

O-C25.

5) Check: During winding, C97 (ratchet spring) should come

securely into contact with C84 (winding halfway switch)

11

(eleven) times.

2.9 Winding lever click switch (C89, C90)

1) Set during winding.

2) C89, C73,

C90, C39, CNL-El.7 x2.0

3) Adjust: Gap

of

Winding lever click switch

C90 should be adjusted so that the switch gap is

between

0.1 and

0.3

mm

in the Winding lever is

at preliminary angle position.

4)

Check: Check switch operation.

a)

Winding lever housing position: SW

/o

ff

b) Winding lever preliminary angle position:

SW/off (0.1 - 0.3 mm)

c) During winding: SW/on

5) One lead wire (pink) should be soldered onto C90.

~\c

O-C28

/~

>0.

1mm

~~~c

~

adj.

~

CNL-E1 .7x2.0

®--c39

__

_

,/

-,,

C90

/~

0

.

1-0

.3

mm

,

I C89 \

t

C73

\,

~

(O-C1))

\,"'- C90

/'

CB9

'-

---/

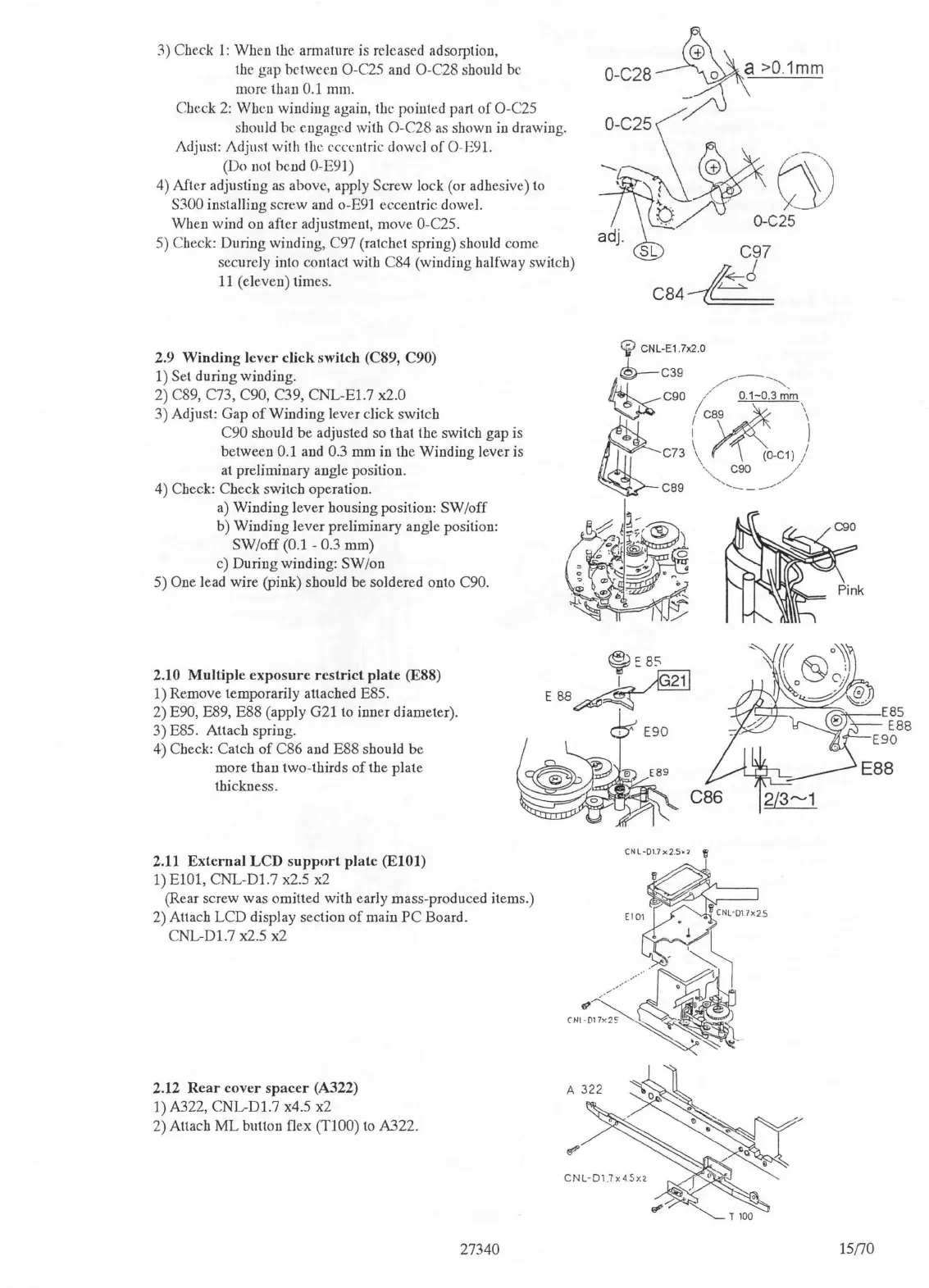

2.10 Multiple

exposure

restrict

plate (E88)

1) Remove temporarily attached E85.

2)

E90, E89, E88 (apply G21 to inner diameter).

~:ss

L~

EBB~~

-

3) E85. Attach spring.

4) Check: Catch

of

C86 and E88 should be

more than two-thirds

of

the plate

thickness.

2.11

External

LCD

support

plate

(ElOl)

1) ElOl, CNL-D1.7 x2.5 x2

(Rear screw was omitted with early mass-produced items.)

2) Attach LCD display section

of

main

PC

Board.

CNL-Dl.7 x2.5 x2

2.12

Rear

cover

spacer

(A322)

1) A322,

CNL-Dl.7

x4.5 x2

2) Attach

ML

button flex

(TlOO)

to

A322.

27340

CNL-Dl.7x2.5.,

~

f?

CNl·01

7

x2~

CNL-Dl.7x4

.

Sn

15170

Loading...

Loading...