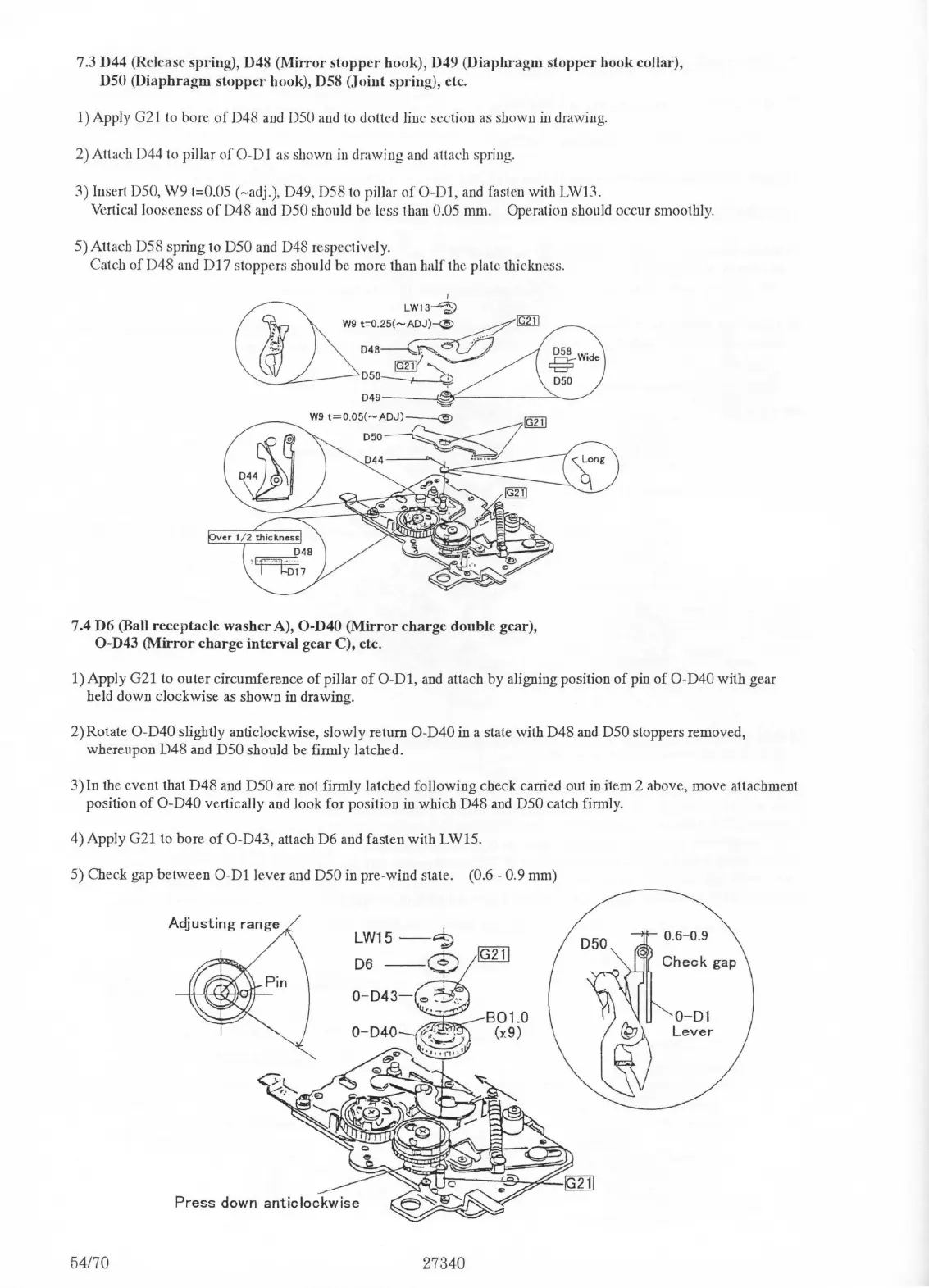

7.3 D44 (Release spring), D48 (MiJTor

stopper

hook),

049

(Diaphragm

stopper

hook collar),

DSO

(Diaphragm

stopper

hook), D58

(Joint

spring), etc.

1)

Apply

G2

J

to

bore

of

D48

and

D50

and

to

dotted line section as shown

in

drawing.

2)

Attach D44

to

pillar

of

0-D

J as shown

in

drawing

and

attach spriug.

3) Insert D50,

W9

t=0.05 (-adj.), D49, D58

to

pillar

of

0 -

Dl,

and

fasten with

LWH

Vertical looseness

of

D48

and

D50 should be less than 0.05 mm. Operation should occur smoothly.

5) Attach D58 spring to

D50

and

D48 respectively.

Catch

of

D48 and

DI

7 stoppers should be more than half

th

e plate thiclmess.

I

LW13~

W9

t

=

0

.

25(-A~[gliJ

048~

-

~"'

058~

049~~~~"§-'2(-~~~~

~-'>...~/

W9

t=0

.

05(-AOJ)--©

[gliJ

:::~

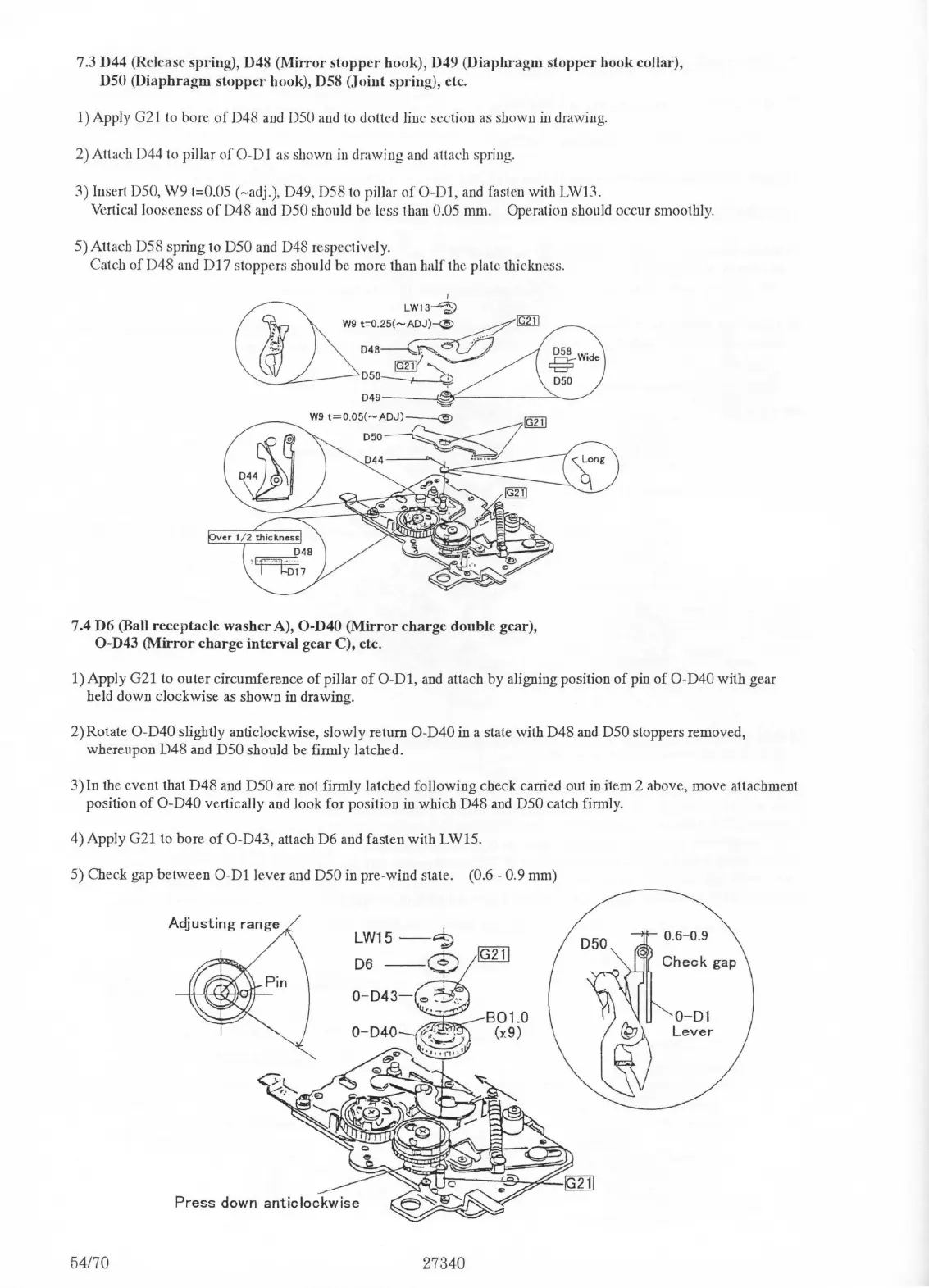

7.4 D6 (Ball receptacle

washer

A), O-D40

(Mirror

charge

double

gear),

O-D43

(Mirror

charge

interval

gear

C), etc.

1) Apply G21 to outer circumference

of

pillar

of

0-Dl,

and

attach by aligning position

of

pin

of

O-D40 with gear

held down cJockwise as shown in drawing.

2)Rotate

O-D40 slightly anticJockwise, slowly return O-D40

in

a state with D48

and

D50 stoppers removed,

whereupon D48 and

D50 should be firmly latched.

3)ln

the.

event that

D48

and

D50 are not firmly latched following check carried out

in

item 2 above,

move.

attachment

position

of

O-D40 vertically and look for position

in

which D48

and

D50 catch firmly.

4) Apply G21 to bore

of

O-D43, attach D6

and

fasten with LW15.

5) Check gap between

0-Dl

lever

and

D50

in

pre-wind state. (0

.6

- 0.9 mm)

54170

LW15

-1;

D6--$

0-Dl

Lever

Loading...

Loading...