76 KENR6932

Disassembly a nd Assembly Section

Note: The crankshaft rear seal and the housing are

manufactured a

s one assembly.

Note: Do not lubricate the crankshaft rear seal or

the crankshaf

t flange. The crankshaft rear seal

must be installed dry.

NOTICE

Keep all parts

clean from contaminants.

Contaminants may cause rapid wear and shortened

component lif

e.

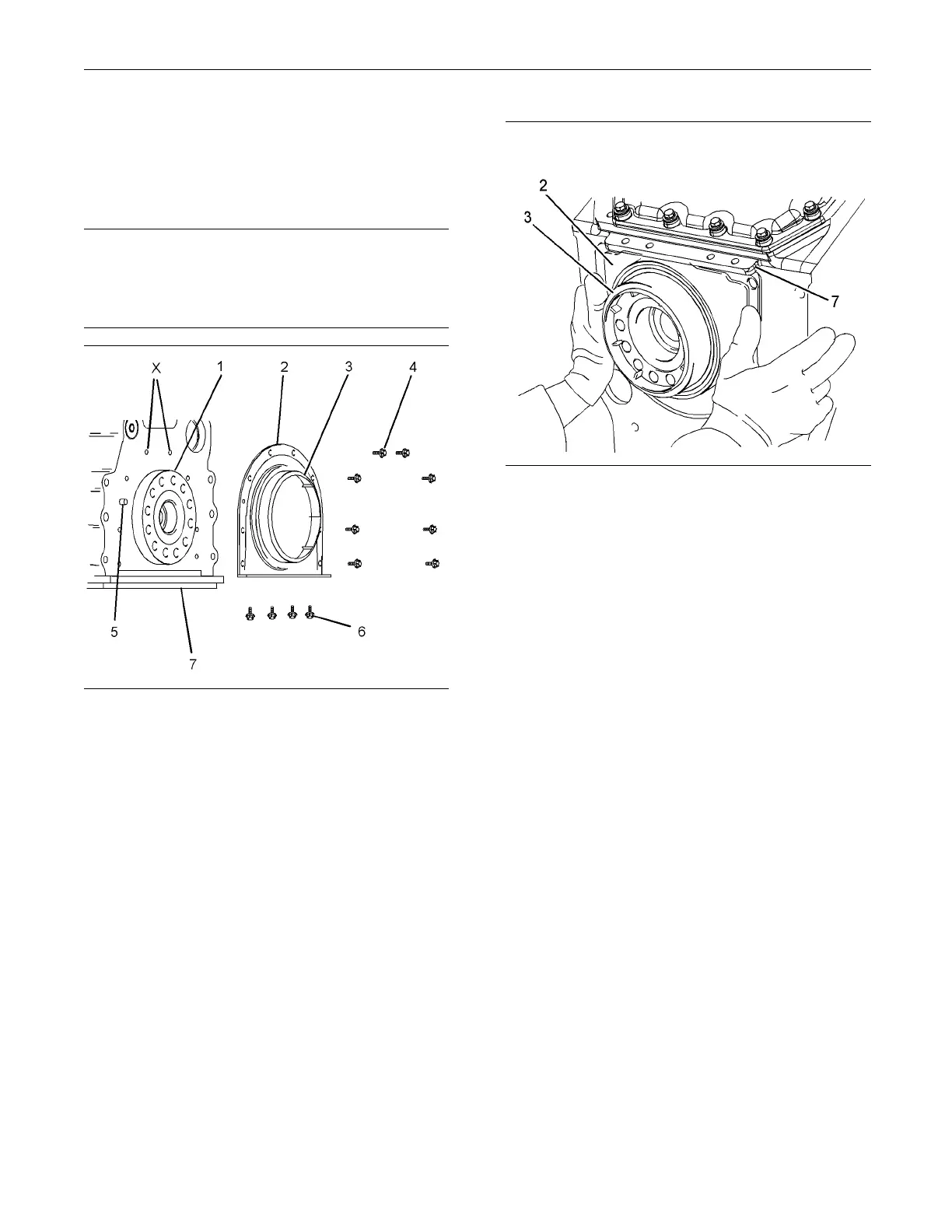

g01337512

Illustration 132

Typical exam p le

1. Ensure that crankshaft flange (1) is clean, dry and

free from damage.

2. Ensure that the mating surface of the cylinder

block is clean and dry. Ensure that the mating

surface of isolating frame (7) is clean and dry.

3. Ensure that plastic sleeve (3) is squarely installed

within new crankshaft rear seal (2).

Note: The plastic sleeve is included in order to

protect the lip of the seal as the crankshaft rear seal

is pushed over crankshaft flange (1). Do not attempt

to install a crankshaft rear seal without the plastic

sleeve.

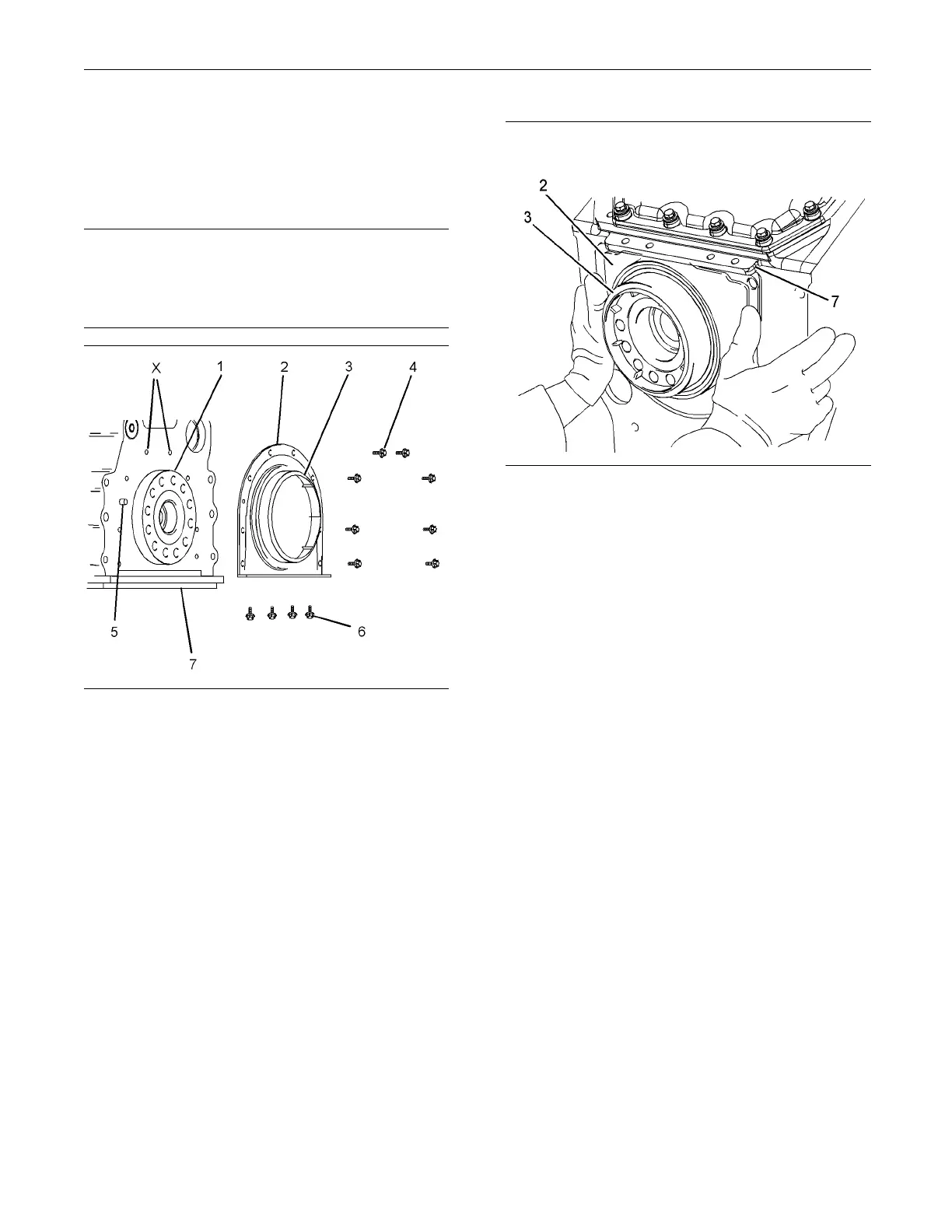

g01337513

Illustration 133

Typical example

4. Place the assembly of the crankshaft rear seal

over crankshaft flange (1). Align dowel (5) with the

slot in crankshaft rear seal (2).

5. Ensure that plastic sleeve (3) is engaged on

crankshaft flange (1). Push crankshaft rear seal

(2) squarely onto the crankshaft. Ensure that the

crankshaft rear seal is seated against the cylinder

block. During this process, plastic sleeve (3) will

be forced out of the crankshaft rear seal. Discard

the plastic sleeve.

Note: Ensure that dowel (5) is engaged in the slot in

the crankshaft rear seal.

6. Use Tooling (A) in order to install two outer Torx

bolts (6) at the base of crankshaft rear seal (2).

TightenTorxbolts(6)toatorqueof15N·m

(11 lb ft).

7. Use Tooling (B) in order to install two Torx bolts (4)

to crankshaft rear seal (2) at position (X). Tighten

Torx bolts (4) to a torque of 22 N·m (16 lb ft).

8. Use Tooling (A) in order to unscrew Torx bolts (6)

by one complete turn.

9. Use Tooling (B) in order to install remaining Torx

bolts (4). Tighten Torx bolts (4) to a torque of

22 N·m (16 lb ft).

10. Use Tooling (A) in order to install remaining Torx

bolts (6). Tighten all Torx bolts (6) to a torque of

22 N·m (16 lb ft).

Loading...

Loading...