ENGINE

3.43

INTAKE VALVE

CLEARANCE

ADJUSTMENT

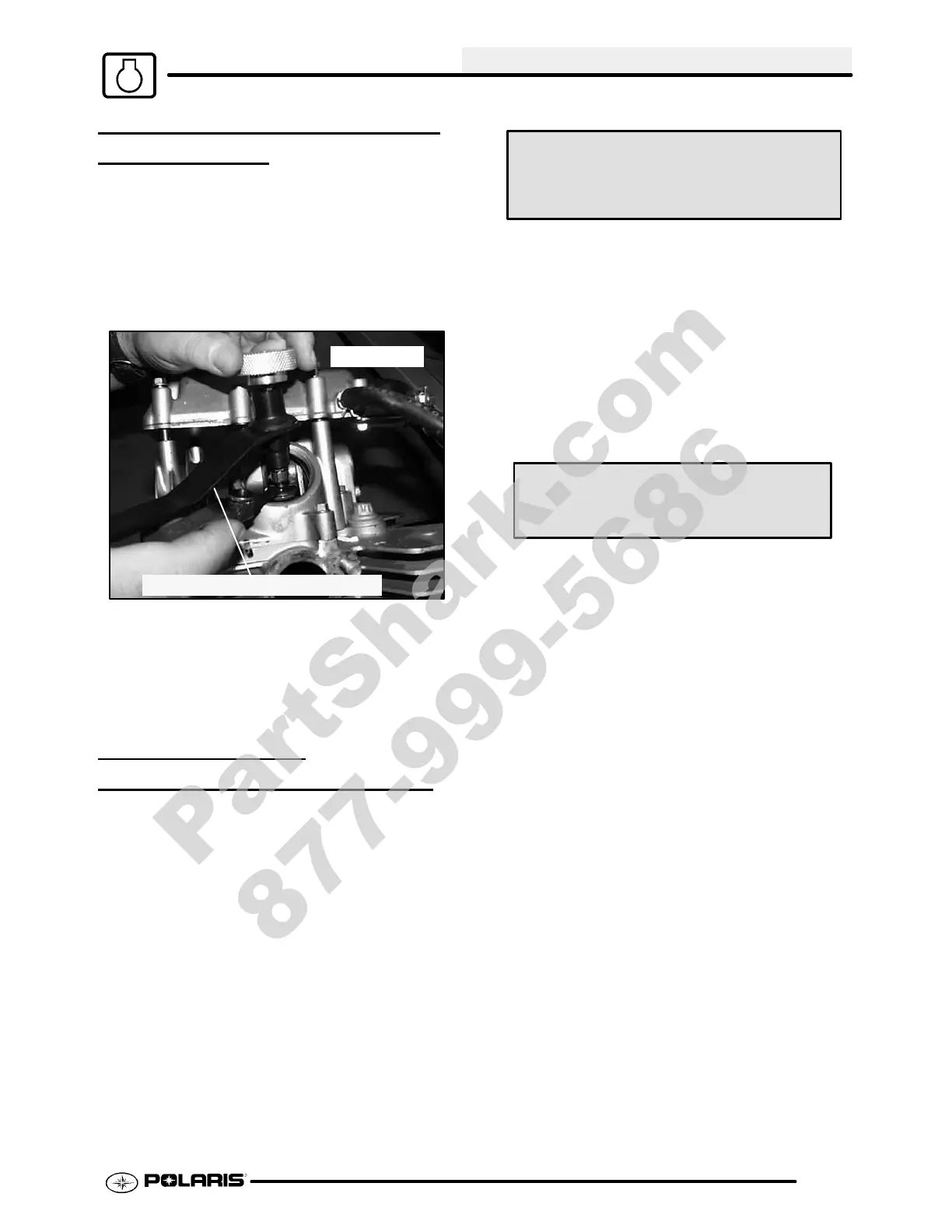

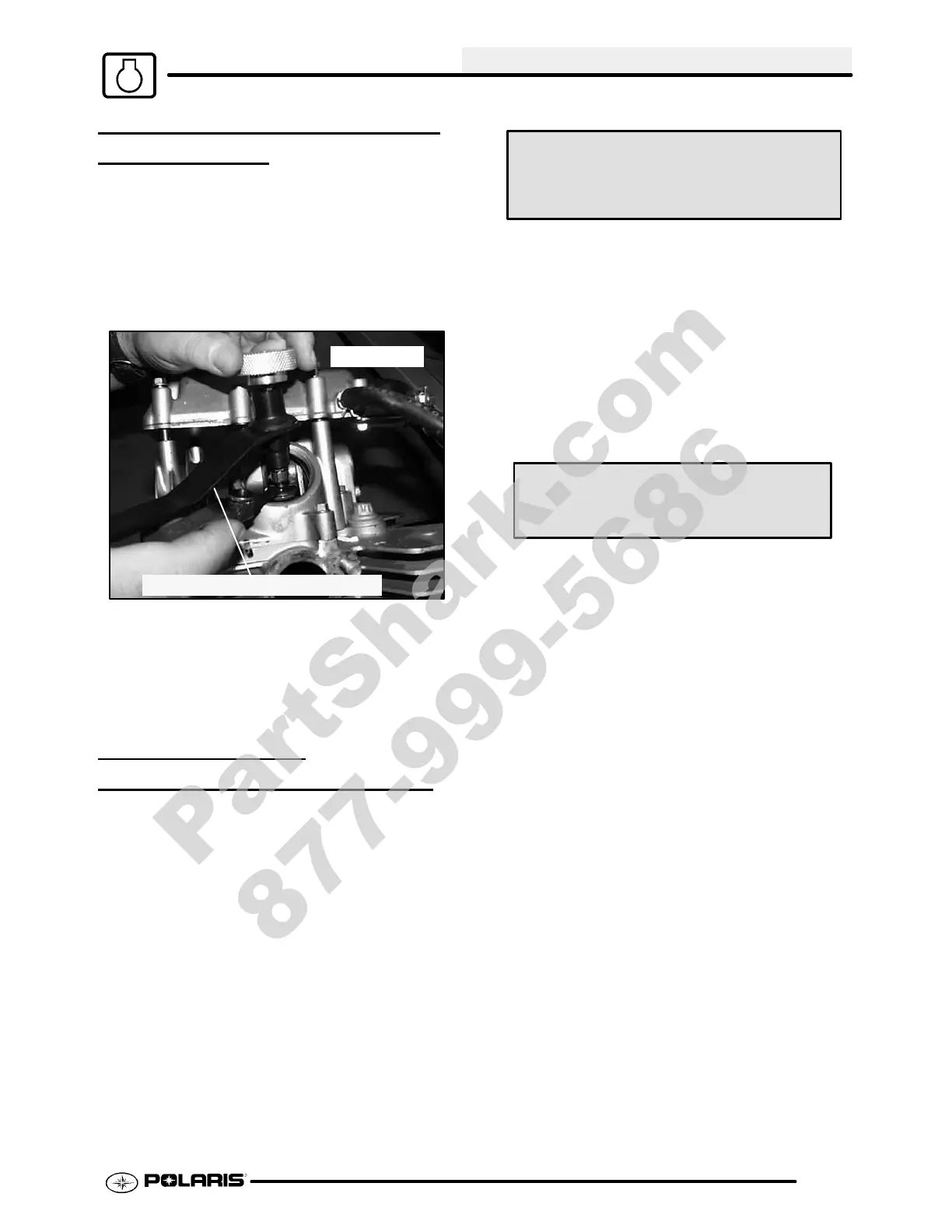

1. Insert a .006″ (.15mm) feeler gauge betweenend

of intake valve stem and clearance adjuster

screw.

2. Using Valve/Clutch Adjuster Tool (PN

PA--44689), loosen adjuster lock nut and turn

adjusting knob until there is a slight drag on the

feeler gauge.

330 Engine

Valve Adjuster Tool: PA--44689

3. Hold adjuster screw and tighten adjuster lock nut

securely.

4. Re-check the valve clearance.

5. Repeat adjustment procedure if necessary until

clearance is correct with locknut secured.

EXHAUST VALVE

CLEARANCE

ADJUSTMENT

1. Insert .006″ feeler gauge(s) between end of

exhaust valve stem and adjuster screw(s).

2. Loosenlocknut(s)andturnadjusterscrew(s) until

there is a slight drag on feeler gauge(s).

NOTE: The 330 exhaust valve is adjusted the same

as the intake valve. The Valve/Clutch Adjuster Tool

(PNPA--44689) canbeusedtoadjustthe330engines

valves.

3. When clearance is correct, hold adjuster screw

and tighten locknut securely

4. Re-check the valve clearance.

5. Repeat adjustment procedure if necessary until

clearance is correct with locknut secured.

330 Engines

.006″ (.15 mm)

VALVE CLEARANCE

6. 330: Inspect o-rings on the plastic valve plugs,

replace if damaged. Securelyfasten valveplugs.

7. Scrape gasket surfaces to remove all traces of

the old gasket.

8. Remove the shop towel from the spark plug

cavity.

9. Install the spark plug. Torque to 14 ft. lbs. (19

Nm).

10. Install the spark plug high tension lead.

11. Install parts removed for access.

330 Engine

Spark Plug Torque: 14 ft. lbs. (19 Nm)

PartShark.com

877-999-5686

Loading...

Loading...