21-2

04

31

4

X

Crusher Operation

2. Refer to specication and plant information for

setting range.

Measuring Discharge Opening

1. Stop the plant, refer to preparing to nish

crushing.

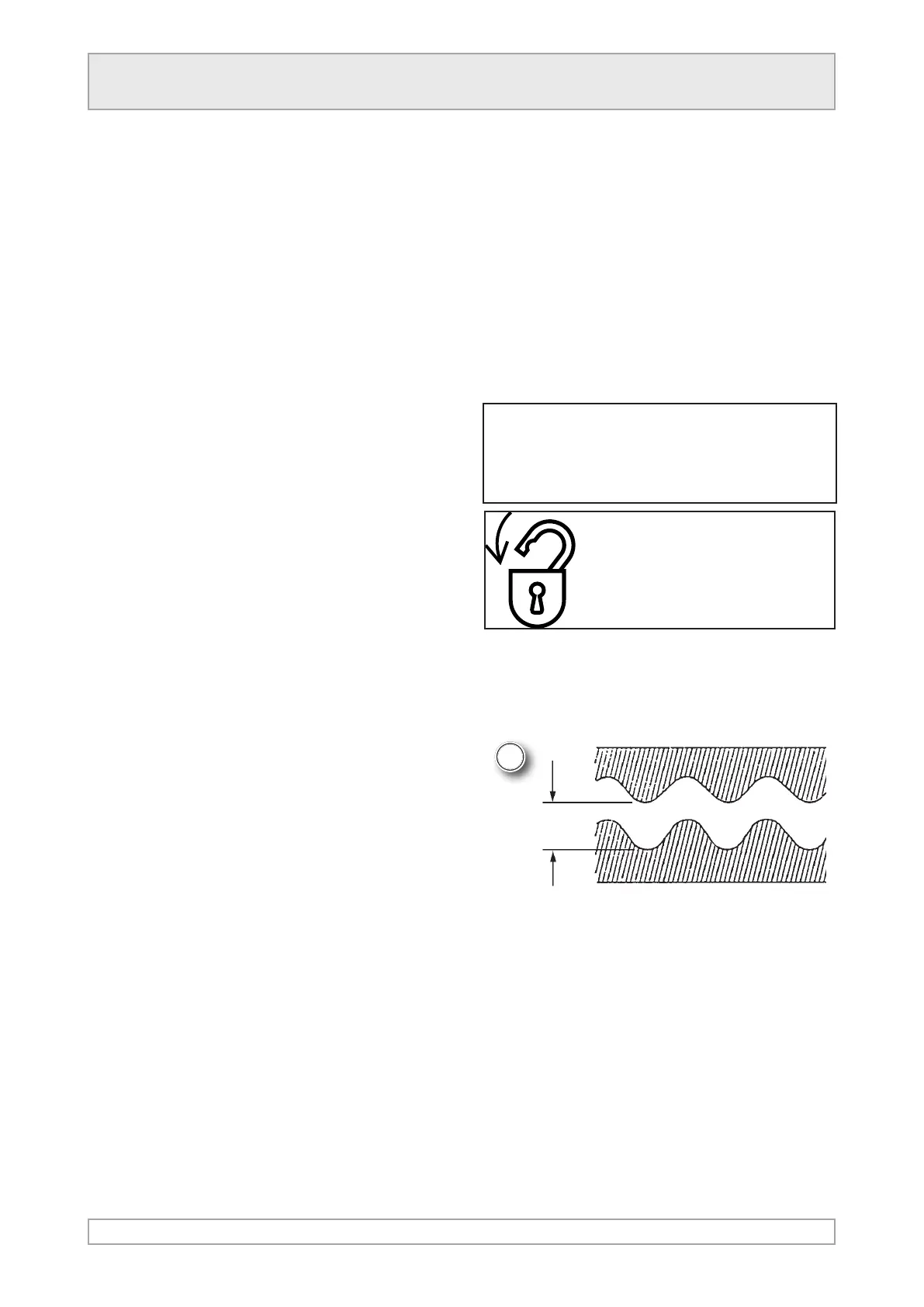

3. The discharge opening is the distance between

the xed and moving jaw plates at the bottom of

the crushing chamber and regulates the size of

the product material.

n WARNING

Refer to Safety Notices Section for relevant

warning and procedure

LOCKOUT PLANT

4. The discharge opening ‘X‘ is measured from

the top of the tooth on one jaw plate to the

corresponding root between two teeth on the

other jaw plate.

5. The opening should ideally be measured when

the jaw is closed, at a point of shortest distance

between the two jaw plates. This is when the

eccentric shaft is at its highest point but the

crusher will not stop naturally at this point.

6. The crusher normally stops with the jaw plates

open, therefore the measured distance is 40mm

(1.5in) above the discharge opening.

7. Measure the distance with the crusher stopped

and subtract 40mm (1.5in) to give the actual

discharge opening.

8. The crusher must be stationary to make

measurements.

Loading...

Loading...