45-8

Servicing Vee Belts

1. Observe all safety warnings.

2. Close down the machine and implement the

Lockout Procedure.

3. Remove the guards from around the belt.

4. Calculate the deection distance in mm (or

inches) on a basis of 16mm (0.6in) deection

per 1 metre (1 yard) of belt span.

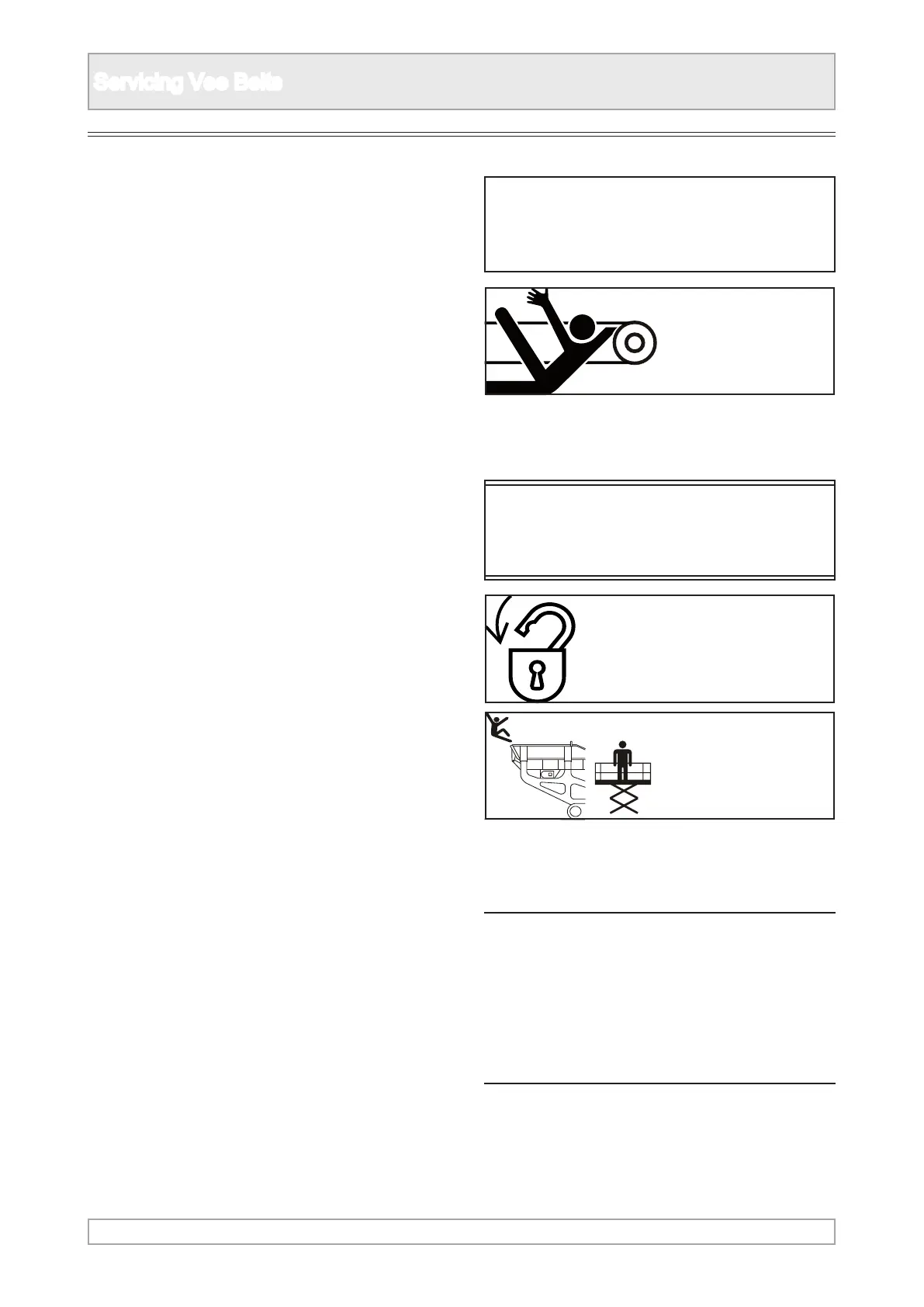

n DANGER

Under no circumstances should any

check on the belt tension be made whilst

the machine is running. There is an

entanglement hazard and risk of trapping

parts of the body.

ENTANGLEMENT

HAZARD

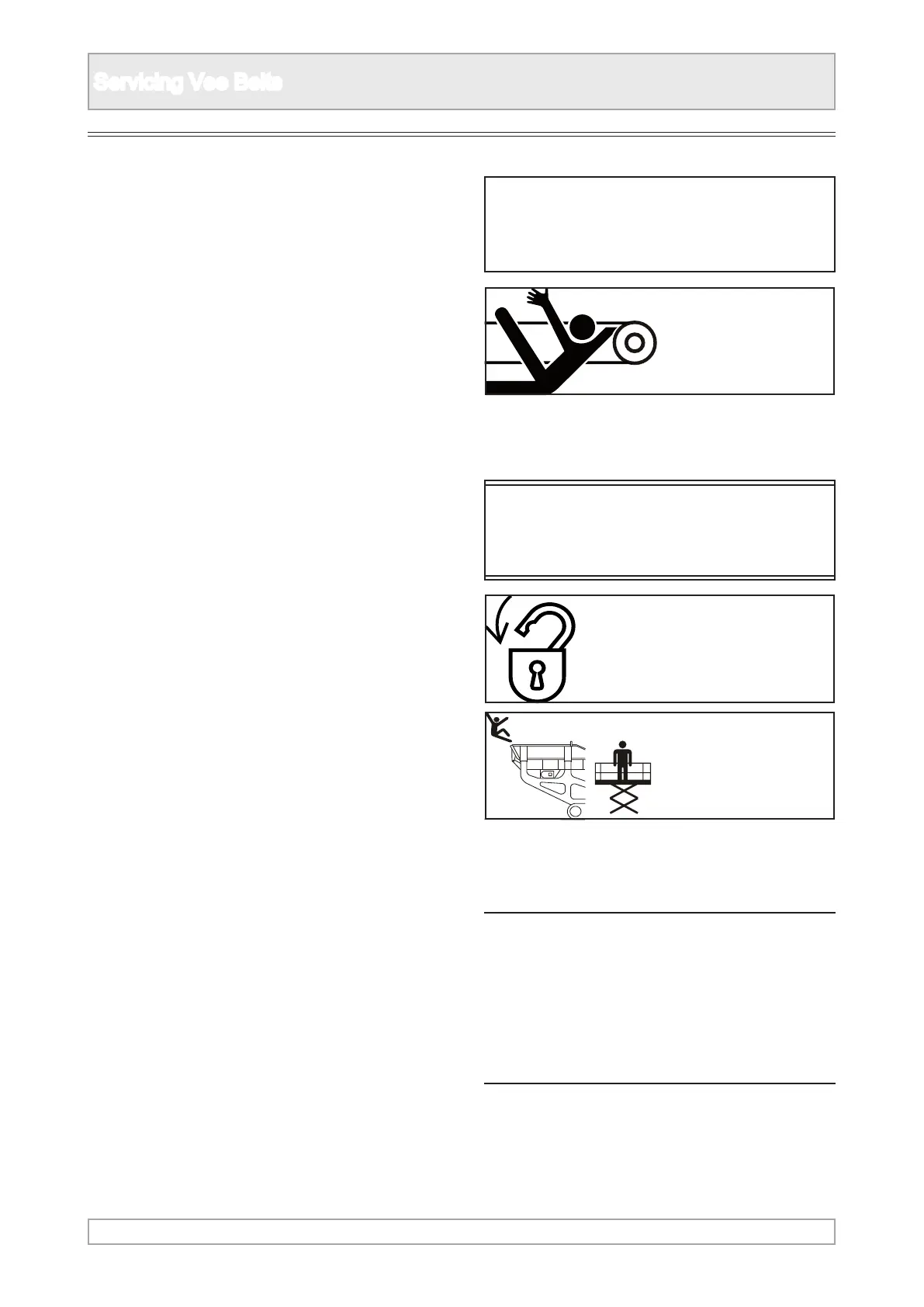

n DANGER

Refer to Safety Notices Section for relevant

warning and procedure

n WARNING

Refer to Safety Notices Section for relevant

warning and procedure

LOCKOUT

PLANT

FALLING

HAZARD

Drive Belt Tension

5. If a belt tension indicator is available:

METRIC: Centre to Centre Distance in metres

x 16 = Deection in mm.

a. Set the lower marker ring at the deection

distance required on the lower scale.

b. Set the upper marker ring against the bottom

edge of the top tube.

c. Place the belt tension indicator on top of the

belt at the centre of the belt span, and apply

a force at right angles to the belt deecting

it to the point where the lower marker ring is

level with the top of the adjacent belt.

d. Read o the setting force value indicated by

the top edge of the upper marker ring.

e. Compare this value to the value shown in the

table.

Loading...

Loading...