45-9

Servicing Vee Belts

EN

a. Use a spring balance to pull the belt down at

the centre of the span.

b. When the belt has been pulled down

[measure using a rule] by the deection

calculated in step 4, read o the force from

the spring balance.

Belt Tensioning Measurements

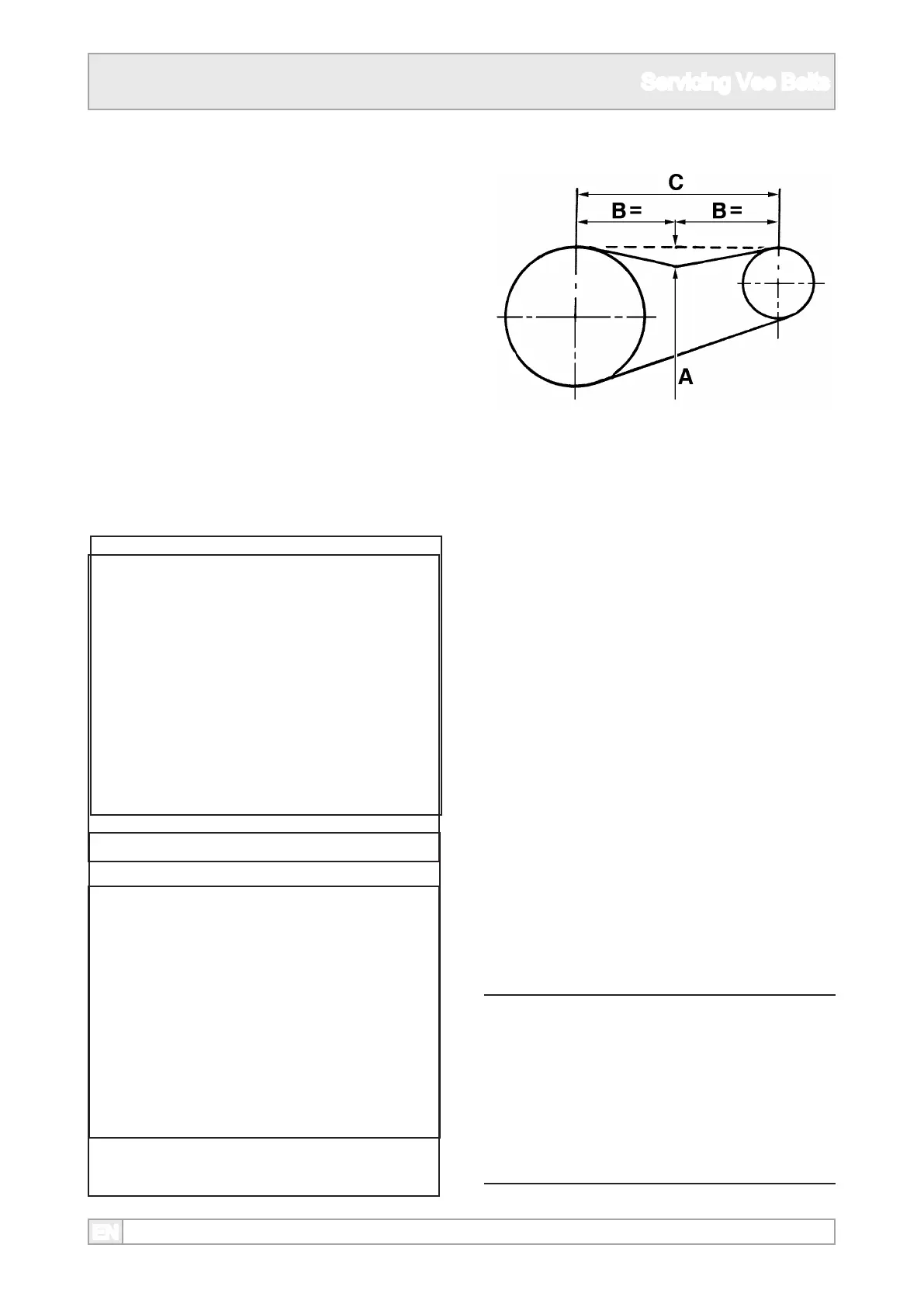

A - 16mm deection per metre (0.6in per 3ft).

B - Belt tension indicator applied to mid-span.

C - Centre to centre distance.

NOTICE

After the drive has been running for 15 to

20 minutes, the plant should be stopped

and the tension checked. If necessary, re-

adjusted to the basic setting force value by

repeating the above procedure from step

1.

[x1] BASIC SETTING FORCES

SPB BELT SECTION

Small Pulley Diameter:

112 to 160mm (4.4 to 6.3in) · · · · 4.0kgf (8.8lbf)

170 to 224mm (6.7 to 8.8in) · · · 5.1kgf (11.2lbf)

236 to 355mm (9.3 to 14.0in) · · 6.3kgf (13.9lbf)

Over 355mm (14in)· · · · · · · · 6.6kgf (14.6lbf)

SPC BELT SECTION

Small Pulley Diameter:

224 to 250mm (8.8 to 9.8in) · · · 7.1kgf (15.7lbf)

265 to 355mm (10.4 to 14in) · · · 9.4kgf (20.7lbf)

Over 375mm (14.8in)· · · · · · · 12kgf (26.5lbf)

[x1.25] BASIC SETTING FORCES

If recommended for new belts

SPB BELT SECTION

Small Pulley Diameter:

112 to 160mm (4.4 to 6.3in) · · · 5.1kgf (11.2lbf)

170 to 224mm (6.7 to 8.8in) · · · 6.3kgf (13.9lbf)

236 to 355mm (9.3 to 14.0in) · · 7.9kgf (17.4lbf)

Over 355mm (14in)· · · · · · · · 8.3kgf (18.3lbf)

SPC BELT SECTION

Small Pulley Diameter:

224 to 250mm (8.8 to 9.8in) · · · 8.9kgf (19.6lbf)

265 to 355mm (10.4 to 14in) · · · 11.8kgf (26lbf)

Over 375mm (14.8in)· · · · · · · 15kgf (33.1lbf)

6. If a belt tension indicator is not available:

7. If the measured force falls within the values

given, the drive should be satisfactory.

A measured force below the lower value

indicates under-tensioning. Some new drive

belts are tensioned to the x1.25 Setting Force

value to allow for the normal drop in tension

during the running-in period. This is not

recommended for all belts.

8. Replace all guards before start-up.

Loading...

Loading...