04-8

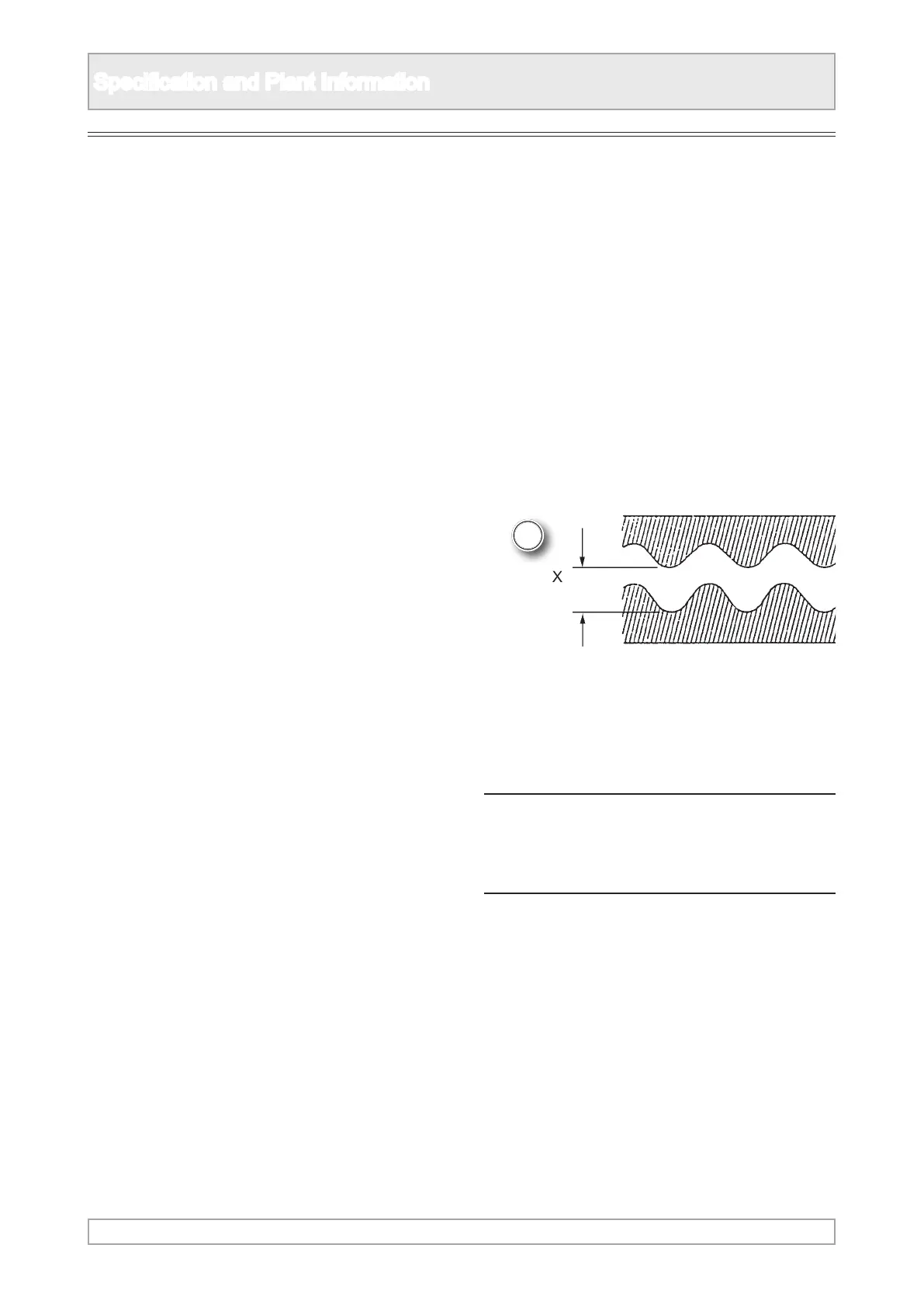

X

4

Specication and Plant Information

4. The crusher must not be operated at a

discharge opening less than shown as ‘X’,

100mm (4in) minimum for quarry applications.

Operating the crusher below this setting may

result in extensive damage.

5. The only exception to this being for crushing

bricks and demolition materials.

1. In order to obtain the optimum output from the

crusher, it’s feed should be continuous and

regulated.

2. All feed should be of a size that will readily enter

the crusher chamber.

3. In order to avoid packing of the discharge

opening and excessive wear of the plant jaws,

under size material should be removed from the

feed prior to entry to the crusher.

NOTICE

DO NOT feed non crushable material

larger than the closed jaw gap setting.

Jaw Crusher

6. The percentage of oversize output from the

crusher, for a given discharge opening, will

depend largely on the quality and character of

the feed material.

7. The crusher has been designed to work with

feed materials having a 10% nes value not

exceeding 390kN (87675 lbf).

Loading...

Loading...