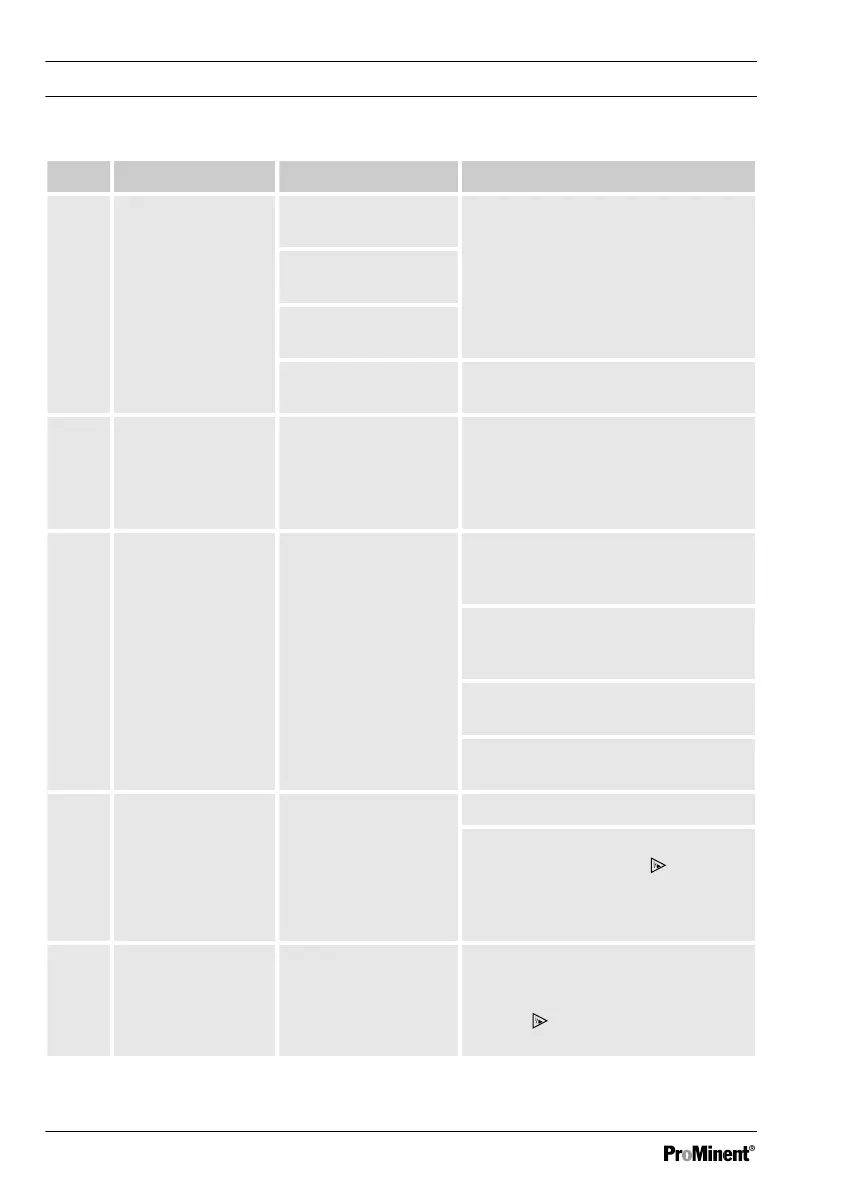

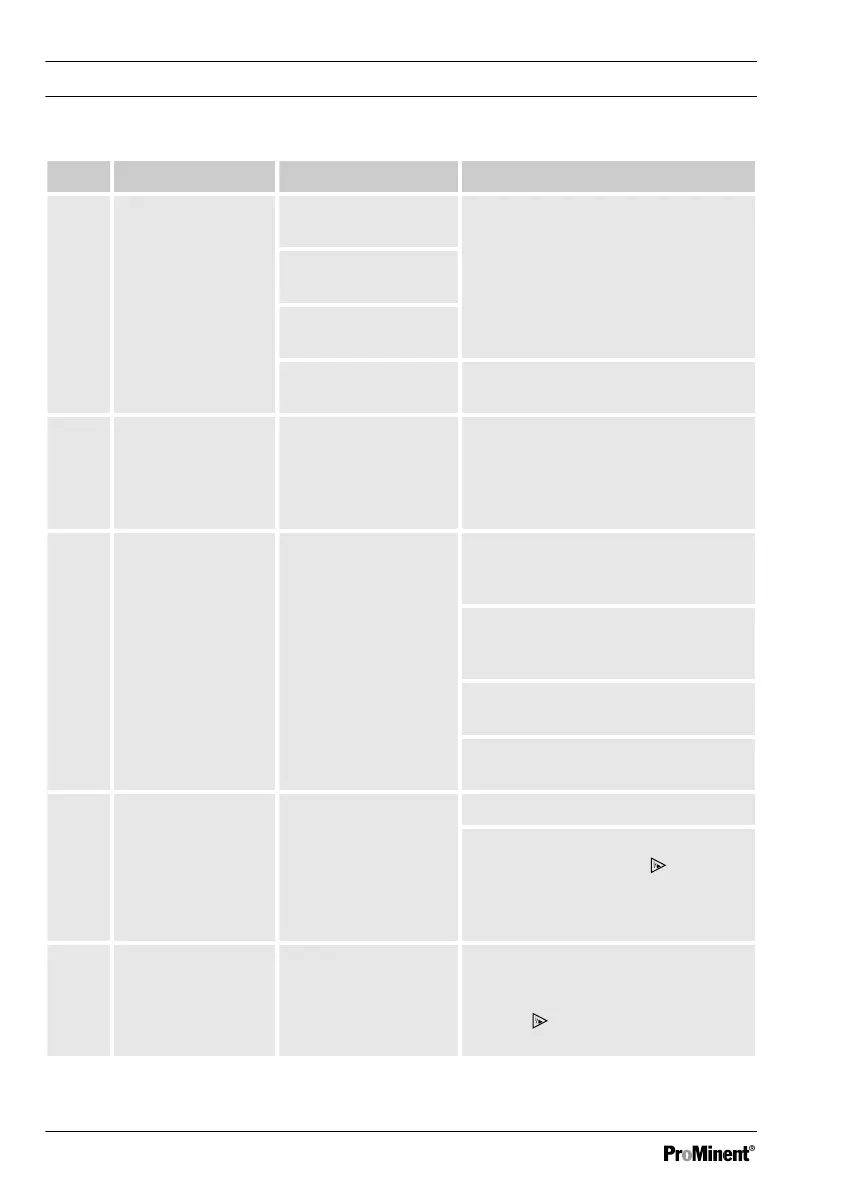

Error Error message text Cause Remedy

06 No sensor detected,

please check the

connection.

Measuring cable con‐

nection disconnected.

Check the correct connection of the

measuring cable connection.

Connect the sensor correctly.

No sensor is con‐

nected.

Cable faulty or not con‐

nected.

Sensor is suspended in

the air.

Install the sensor correctly in the

bypass fitting.

07 Check the mechan‐

ical state of the

sensor. Glass

breakage is pos‐

sible.

Diaphragm glass

broken.

Replace sensor.

Check the reason for the broken glass

e.g. solids, too high a flow velocity.

08 The checkout time

was transgressed.

In the

[Control]

menu,

the set control variable

has exceeded the

threshold for a longer

time than the checkout

time control variable.

The control section needs a longer time

to regulate itself than the selected

checkout time.

The control section needs a greater

control variable threshold to regulate

itself than the selected one.

The metering chemical is empty or has

a too low/high a concentration.

The metering line is disconnected or

the point of injection blocked.

09 The mA input current

is too high.

The current is greater

than the maximum per‐

mitted current of 23

mA.

Check the origin of the current.

Check the raw value in mA in the Infor‐

mation menu by pressing . If the

value is >23 mA, then it is not a correct

sensor signal. Replace the sensor with

a new sensor.

10 The mA input current

is too low.

The power circuit is

disconnected.

Check the 2-wire connection between

the sensor/transmitter and controller

and check the raw value in mA by

pressing . If the value is 0 mA, then

the connection is disconnected.

[Diagnostics]

168

Loading...

Loading...