7–12 Schematics

Publication 1336 IMPACT-6.8 – November, 2002

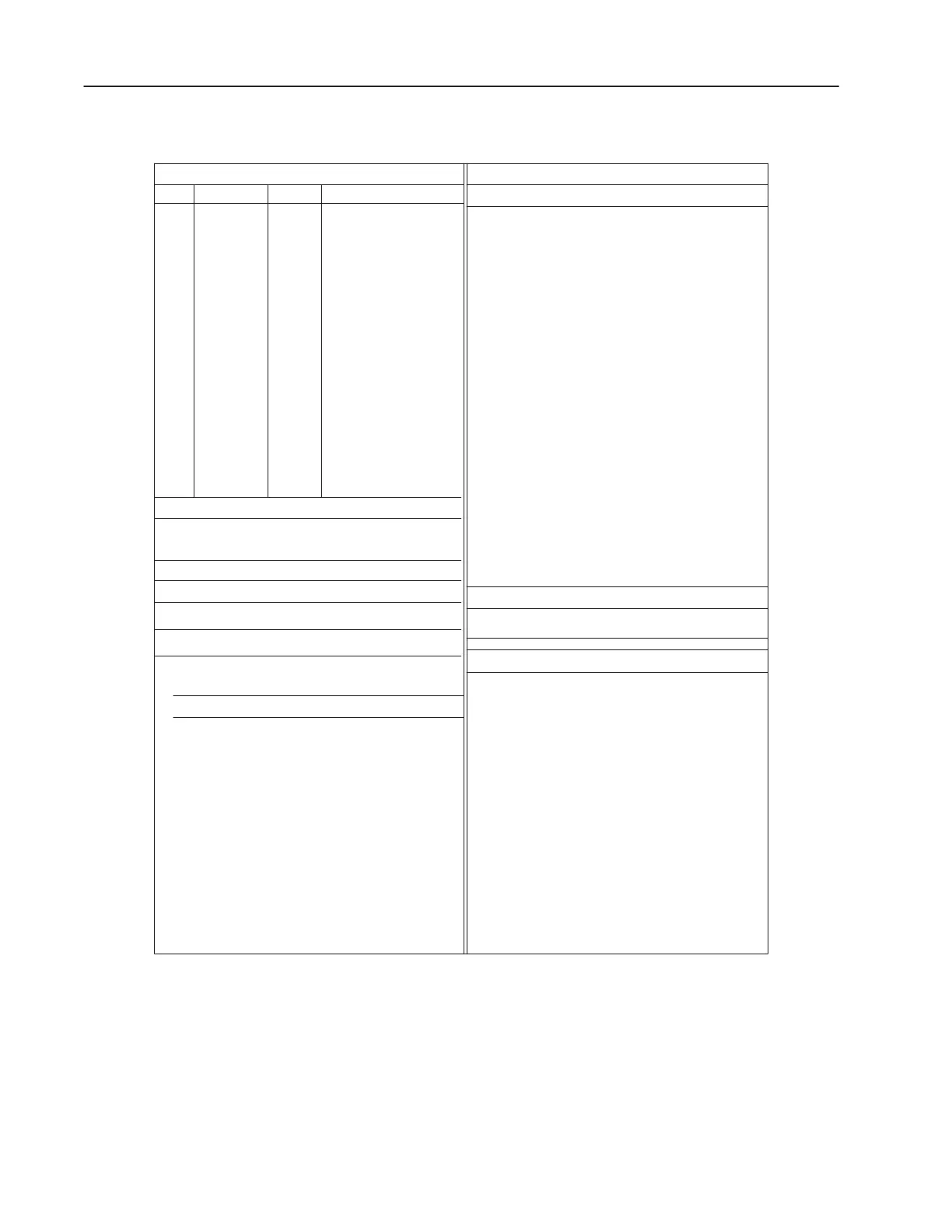

INTERCONNECTION INFORMATION

NO. WIRE RANGE TYPE

WIRE SOURCE EXPLANATION TERMINAL CABLE

SEE INSTRUCTION MANUAL FOR CABLE CLASSES

CLASSES 5 AND 6 ARE CONTROL WIRES, 15 AMPS OR LESS

SHIELD(S) REMAIN CONTINUOUS AND INSULATED FROM GROUND.

CABLES, IF NECESSARY, SHOULD BE DONE SUCH THAT THE

BE CONNECTED AT BOTH ENDS. THE SPLICING OF SHIELDED

SHIELDS FOR SHIELDED POWER CABLE (MOTOR LEADS) MUST

BE CONNECTED AT THE CABINET END OF THE CABLES.

SHIELDED CABLE FROM A CABINET TO AN EXTERNAL DEVICE

AND INSULATED. IT IS RECOMMENDED THAT SHIELDS FOR

AT ONE END ONLY. THE OTHER END SHOULD BE CUT BACK

5. SHIELDS FOR SHIELDED SIGNAL CABLE MUST BE CONNECTED

MAXIMUM LOAD (FLA).

SHOULD BE USED WHERE POSSIBLE.

TABLE 310–16 (755C)

AS SHOWN FOR CABLE TRAYS.

1. CUSTOMER TERMINALS ARE SIZED FOR 755C WIRE PER NEC

2. STEEL CONDUIT IS RECOMMENDED FOR ALL WIRING CLASSES,

BUT IS REQUIRED FOR SIGNAL CATEGORY CLASSES.

ALUMINUM CONDUIT REQUIRES THE SAME MINIMUM SPACING

3. SPACES BETWEEN CLASSES SHOWN IN THE INSTRUCTION

MANUAL IS THE MINIMUM REQUIRED FOR PARALLEL RUNS

EQUAL TO OR LESS THAN 400 FEET. GREATER SPACING

4. No. 16 Ga. WIRE IS THE MINIMUM RECOMMENDED SIZE FOR

CONTROL WIRE. POWER WIRE IS SELECTED BY CONTINUOUS

GENERAL WIRING NOTES

MATERIAL LIST – COMPONENTS

DESCRIPTIONSYM.

CONTROL

CLASS WIRE SOURCE EXPLANATION TERMINAL CABLE

NO. NO. WIRE RANGE TYPE

CLASSES 7 THROUGH 12 ARE SIGNAL WIRES, 5 AMPS OR LESS

SEE INSTRUCTION MANUAL FOR CABLE CLASSES

INTERCONNECTION INFORMATION

SIGNAL

NO. WIRE RANGE

CURR. WIRE SOURCE EXPLANATION TERMINAL

SEE INSTRUCTION MANUAL FOR CABLE CLASSES

INTERCONNECTION INFORMATION

MANUFACTURER/PART NO.

PART NO.

A–B

WIRING REQUIREMENTS

EXTERNAL INTERCONNECT

POWER

SEE 1111 OL1(T1) FAN1 #14Ga

965 L1 TB11–1 INCOMING 500LB–IN (4)2Ga–600M

SEE 2 N/A 1T1 EA1–TB1(U) AC MOTOR (3)#14–600M

N/P 1T3 EA1–TB1(W)

MTR 1T2 EA1–TB1(V)

N/P 1113 OL1(T3)

MTR 1112 OL1(T2)

FRAME MTR–PE

L2 TB11–2 460 V LINES

FRAME MTR–PE

2 GRND LINE–PE GROUND EQMT

L3 TB11–3

CONDUCTOR

4063 F6–1 115VAC 22–14 Ga PER

4065 FROM CUSTOMER NEC

GND CHASSIS GND

AB/100–C09D10

AB/193–EA4DB

GRAND/C042

BUSSMANN/CCMR–5

COLLMER/CS9107A4

EBM/W2E250–CB13–51

EBM/RH45M–4/125497

BUSSMANN/SPP–700

BUSSMANN/FNM–9

A–B/MEQUON

1336E–R800–AN–EN–L6

TIMEMARK/C263

EUPEC/2B6U 575/775–800F/

3KM17L 6DD600N–T

AB/1336–L6

300642

300658

177300

146927

166095

186190

310238

504923

159010

170684

N/A

128229

177187

161428

CONTACTOR

OVERLOAD

CHOKE

FUSES

SURGE SUPPRES

FAN MOTOR

FAN MOTOR

FUSES

FUSE

SUPPRESSOR

DRIVE UNIT

RELAY

BRIDGE

15VAC CNTRL

M12

OL12

CH10

F20–22

MOV

FAN2

FAN1

F1–3A

F6

EA12

EA1

EA11

EA10

EA1

3212 TB3–19 CODE

3201 TB4–6 START PB #22–14 Ga. PER

3232 TB3–20 CODE

3201 TB4–6 STOP PB #22–14 Ga. PER

Sheet 7 of 7

Loading...

Loading...