12 Rockwell Automation Publication 2198-RM002A-EN-P - October 2017

Chapter 1 System Replacement Considerations

Checklist for Kinetix 6000

Servo Drive System

Migration

For each Kinetix 6000 drive control feature, there is a suitable solution with the Kinetix 5700 servo drives,

LOGIX 5000™ controller platforms, and the Studio 5000 Logix Designer® application. Use the following table as a

checklist of common considerations when migrating from Kinetix 6000 drives to Kinetix 5700 drives.

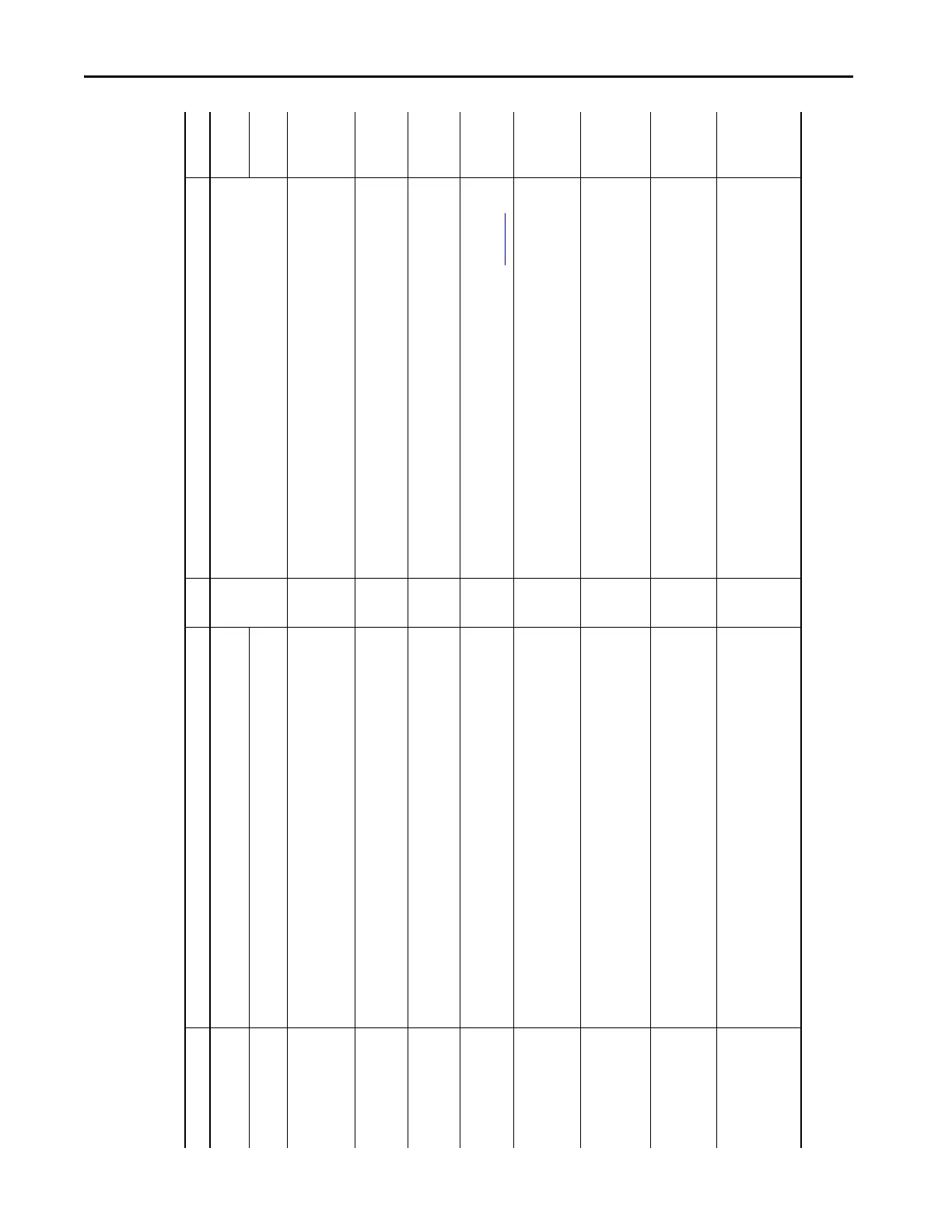

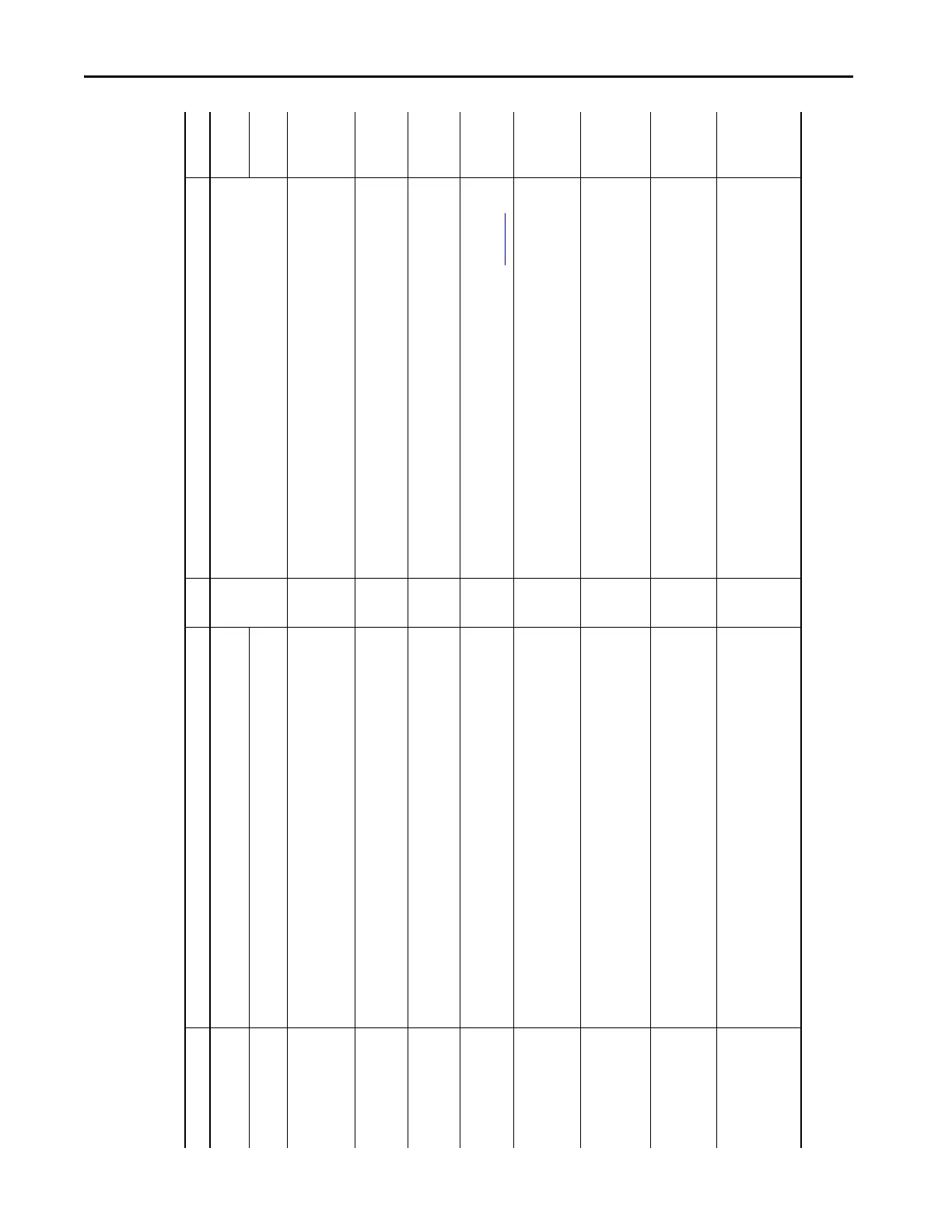

Table 1 - Migration Checklist

Feature/Function Kinetix 6000 Drive Features Page Kinetix 5700 Drive Replacement Features Complete?

Rotary Motor

Compatibility

The Kinetix 6000 servo drives support 1326AB, MP-Series™ (Bulletin MPL, MPM, MPF, MPS),

and RDD-Series™ rotary servo motors.

19

You can continue to use the existing compatible motors/actuators with the Kinetix 5700

servo drives, however, feedback compatibility restrictions apply.

Linear Motor/Actuator

Compatibility

The Kinetix 6000 servo drives support LDC-Series™ linear motors, MP-Series (Bulletin MPAS,

MPMA, MPAR, MPAI) linear actuators, and LDAT-Series linear actuators.

Customer-supplied

External 24V DC Power

Supply for Motor Brakes

The Kinetix 6000 IAM and AM (inverter) modules require an external customer-supplied

24V DC input for motor brakes. The Motor Brake (BC) connector on each IAM and AM

module provides programmable motor-brake relay outputs and supply an MOV device for

arc suppression.

22

The Kinetix 5700 drive modules require an external customer-supplied 24V DC power

supply for control power, digital inputs, and motor brake power. The Motor Brake (BC)

connector on each inverter provides programmable motor-brake relay outputs and supply

an MOV device for arc suppression.

Digital Input and

Registration Input Power

Supplies

The Kinetix 6000 has an internal 24V DC power supply on each IAM/AM module that is

dedicated for use by the enable, home, and overtravel digital inputs, and two registration

inputs.

23

The Kinetix 5700 drive modules require an external customer-supplied 24V DC power

supply for control power, digital inputs, and motor brake power.

I/O Terminations

The Kinetix 6000 IAM and AM modules each have their own dedicated I/O (IOD) connector

for terminating the individual I/O points for each axis. Each IOD connector requires a low-

profile connector kit (catalog number 2090-K6CK-D26M).

23

The Kinetix 5700 single-axis and dual-axis inverters have four configurable digital inputs

with fast response times and ten I/O functions to choose from in the Logix Designer

application. Digital inputs connect directly to the IOD connector.

Hardware Enable Inputs

The Kinetix 6000 IAM and AM modules each have their own Hardware Enable input on the

I/O (IOD) connector. Each IOD connector requires a low-profile connector kit (catalog

number 2090-K6CK-D26M).

23

The Enable input is one of ten I/O functions that you can assign to one of four configurable

inputs that require 24V DC. Digital inputs connect directly to the IOD connector. See

Switched Mode Power Supply Specifications Technical Data, publication 1606-TD002

.

Safe Torque-off (STO)

The Kinetix 6000 servo drives offer a 9-pin hardwired safe torque-off (STO) connector for

wiring single and multiple safe torque-off drive configurations. A jumper lets you defeat

(not use) the safe torque-off function.

24

The Kinetix 5700 dual-axis and single-axis inverters are equipped for hardwired safe

torque-off (STO) and integrated STO over the EtherNet/IP™ network. Jumper wires that are

inserted in the STO connector let you defeat (not use) the safe torque-off function.

GuardLogix® 5570 or GuardLogix 5580 controllers are required for safety configuration.

Typical Input Power

Components

• 324…528V AC, 50/60 Hz, 3-phase input

• 95…264V AC, single-phase control power supply

• Disconnect, fuse block, main contactor

• 24V DC power supply for motor brakes and motor thermal contacts

31

The Kinetix 5700 input power requirements are similar to the Kinetix 6000 drives, except

Kinetix 5700 systems require an external 24V DC supply for control power, digital inputs,

and motor brake power.

Consider reusing some of your Kinetix 6000 input power components.

Relay Outputs to Help

Protect Drive Electronics

(precharge circuit)

The Kinetix 6000 IAM module provides a Contactor Enable (CED) connector for the same

purpose. Wiring the contactor enable relay into your control string is required.

34

The Kinetix 5700 DC-bus supply provides the Contactor Enable (CED) connector to help

protect the drive system if overloads or other fault conditions occur. An AC three-phase

mains contactor must be wired in series between the branch circuit protection and the

DC-bus power supply.

DC Common-bus

Capability

Configure the Kinetix 6000 IAM module in RSLogix 5000® software or the Studio 5000 Logix

Designer application as a common-bus leader or common-bus follower drive, based on

system needs for regeneration or configuration requirements. When planning your panel

layout, the common-bus leader must be configured to include the common-bus follower

capacitance, because it controls system precharge and shunt control.

49

The Kinetix 5700 servo drive system is based on DC-bus sharing. The axis inverters (single

and dual-axis inverters) require a DC-bus supply that is configured in the Studio 5000 Logix

Designer application (formally RSLogix 5000).

We recommend using Motion Analyzer to size and select the appropriate DC-bus supply for

your Kinetix 5700 system.

Loading...

Loading...