50 Rockwell Automation Publication 2198-RM002A-EN-P - October 2017

Chapter 3 System Replacement Examples

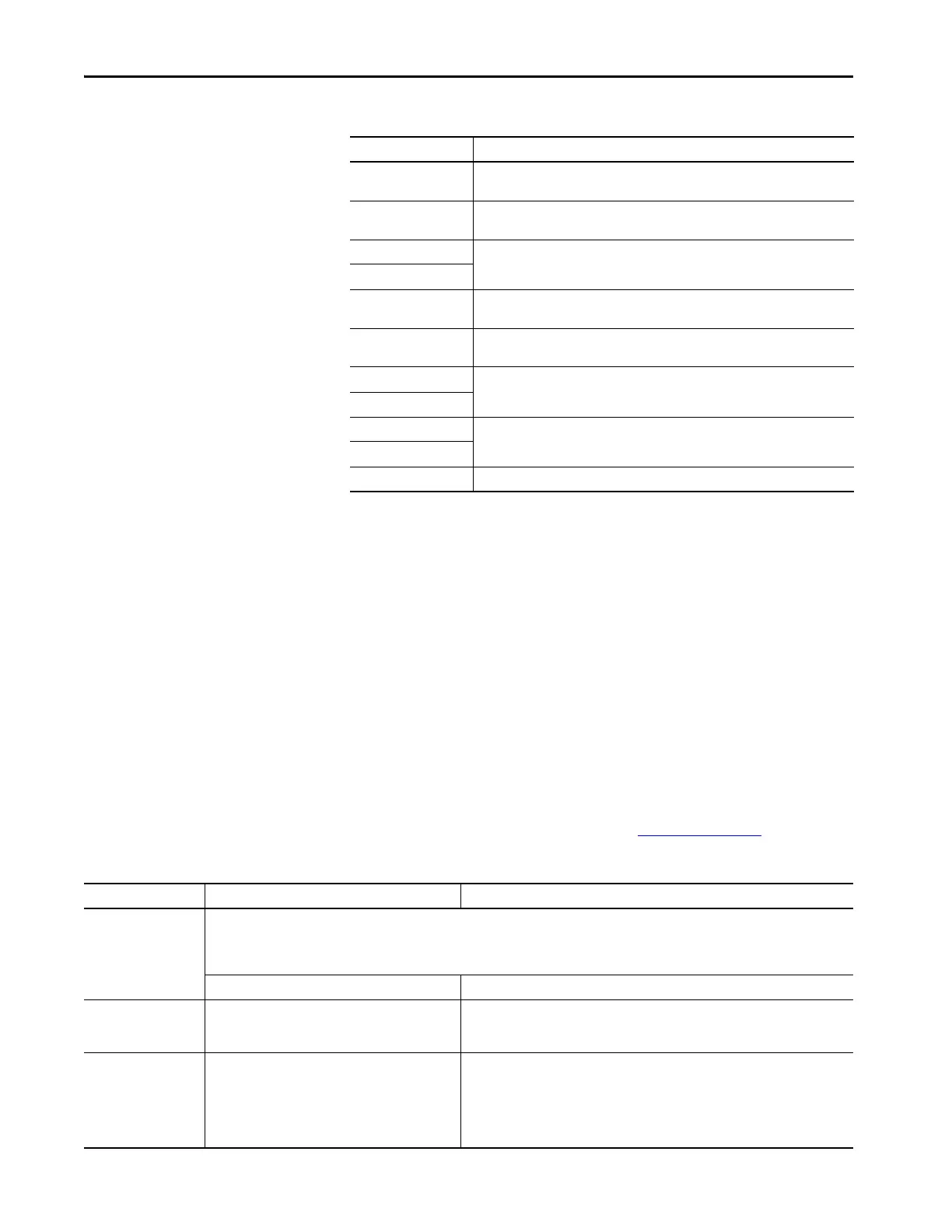

Table 19 - Kinetix 5700 Fault Code Summary

Tuning

Closed-loop servo systems require settings for the control-loop gain and filter

values to make sure that the load accurately follows the desired input-command

signal. The process of adjusting and refining the gain and filter configuration is

called tuning.

Tuningless features help you reduce commissioning time, maintain product

quality, sustain operation with lower downtime, and improve machine

performance.

For help tuning your axes, see the Tuningless Features for the Kinetix 5000

Servo Drive Family Quick Start, publication MOTION-QS001

.

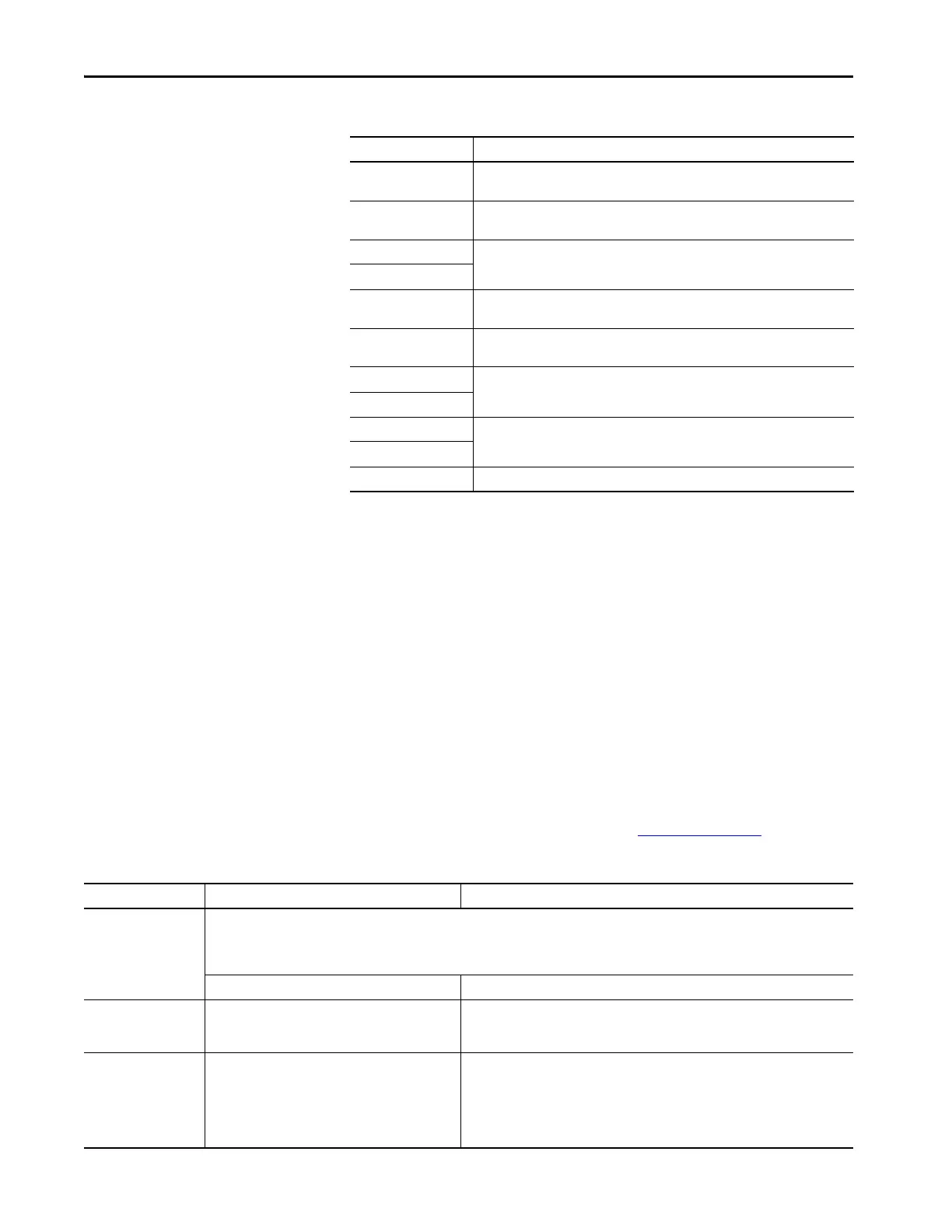

Table 20 - Motion System Tuning

Fault Code Type

(1)

(2)

(1) Sxx refers to Standard exceptions.

(2) Mxx refers to Manufacturer-specific exceptions.

Description

FLT Sxx

Standard runtime axis exceptions. The exception can apply to an individual axis or to

all axes.

FLT Mxx

Manufacturer-specific runtime axis exception. The exception can apply to an individual

axis or to all axes.

INIT FLT Sxx

Exceptions that help prevent normal operation and occur during the initialization

process.

INIT FLT Mxx

NODE FLTxx

Exceptions that help prevent normal operation of the drive module and apply to the

entire module and affect all axes.

NODE ALARM xx

Exceptions that help prevent normal operation of the drive module, but do not result in

any action other than reporting the alarm to the controller.

INHIBIT Sxx

Conditions that help prevent normal operation and indicate that the drive module is

prevented from being enabled.

INHIBIT Mxx

ALARM Sxx

An underlying exception condition that does not result in any action other than

reporting the alarm to the controller.

ALARM Mxx

SAFE FLTxx Exception that is generated by a fault condition that is detected in the safety function.

Tuning Methods Kinetix 6000 Drives Kinetix 5700 Drives

Load Observer

• Operates in real-time

• Estimates and compensate for mechanical load inertia on motor

• Controls motor as if unloaded

• Compensates for mechanical variations in system such as changing loads, compliance, and machine wear over time

Configure Kinetix 6000 drives via message instructions Configure Kinetix 5700 drives in Logix Designer>Axis Properties via Add-on Profile

Adaptive Tuning with

Tracking Notch Filter

Adaptive tuning feature is not supported.

• Operates in real-time

• Measures mechanical resonances and dynamically sets the notch filter frequency to

mitigate the resonances

Adaptive Tuning with

Gain Stabilization

Adaptive tuning feature is not supported.

• Enables and tunes the low-pass filter to suppress resonances if any are identified

above the low-frequency limit (when there are more resonances in the system than

notch filters in the drive).

• Adjusts the torque low-pass filter, the control loop gains, and the load observer

bandwidth from the current values until the identified HF resonances are suppressed

or until a LF resonance or instability is attenuated enough to make the system stable.

Loading...

Loading...