48 Rockwell Automation Publication 750-TG100B-EN-P - June 2019

Chapter 3 Component Inspection and Test Procedures

4. Select the “Diode Test” mode on the digital multi-meter and complete the

forward and reverse biased diode tests on the power module as identified

in Tabl e 6

and Table 7.

• For frames 5 and 6 terminal locations, see Figure 5

on page 49.

• For frame 7 power module terminal locations, see Figure 6

on page 50.

• For frames 8…15 power module terminal locations, see Figure 7

on

page 51

.

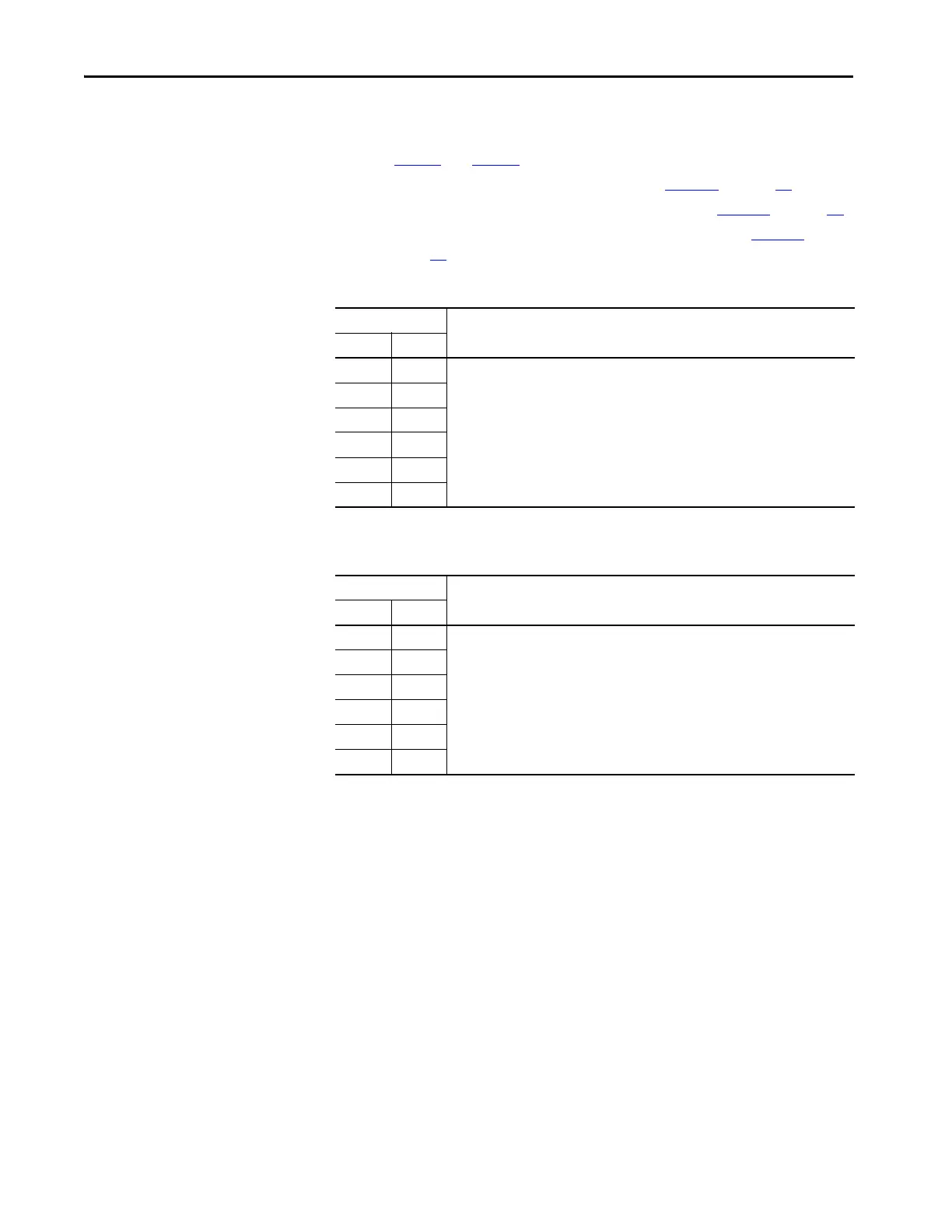

Table 6 - Forward Biased Diode Tests on the IGBT Assembly

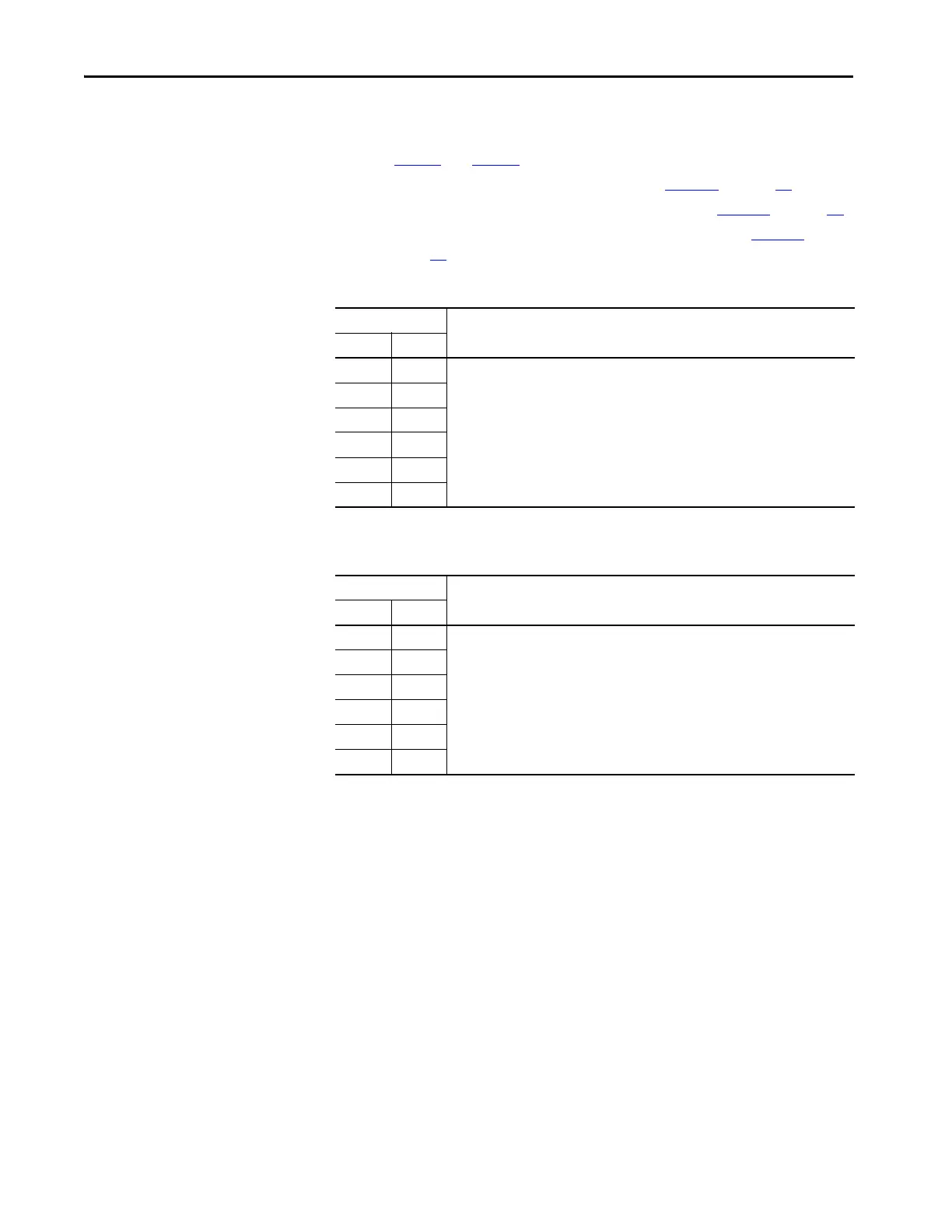

Table 7 - Reverse Biased Diode Tests on the IGBT Assembly

Meter Leads

Nominal Meter Reading+–

–DC U/T1

The value should gradually rise to between 0.20V and 0.75V. If the value is outside this range,

contact Technical Support.

(1)

(1) The actual voltage reading can vary depending upon your equipment.

–DC V/T2

–DC W/T3

U/T1 +DC

V/T2 +DC

W/T3 +DC

Meter Leads

Nominal Meter Reading+–

U/T1 –DC

“.0L” (open circuit)

(1)

(1) Residual voltage on the DC bus capacitors can affect this reading. If the capacitors are discharged (less than 1 volt), the meter

initially shows a low voltage. This voltage reading is the residual bus voltage plus the drop through the low side diodes. The meter

gradually charges the bus, and the voltage slowly increases, until eventually the meter switches to “.OL”. This increase can take

several minutes to occur.

V/T2 –DC

W/T3 –DC

+DC U/T1

+DC V/T2

+DC W/T3

Loading...

Loading...