78 / 291 - EN -

Step Display Icon Description Remark

9

1

The

j

key saves the value.

As an example, the value “1” has been

set for parameter no. 45 (additional

switching output).

10

The control system display

goes dark for a moment and

the control system restarts.

11

20

After the restart, the control unit

is ready for operation again.

The set value is now permanently saved

for the respective parameter.

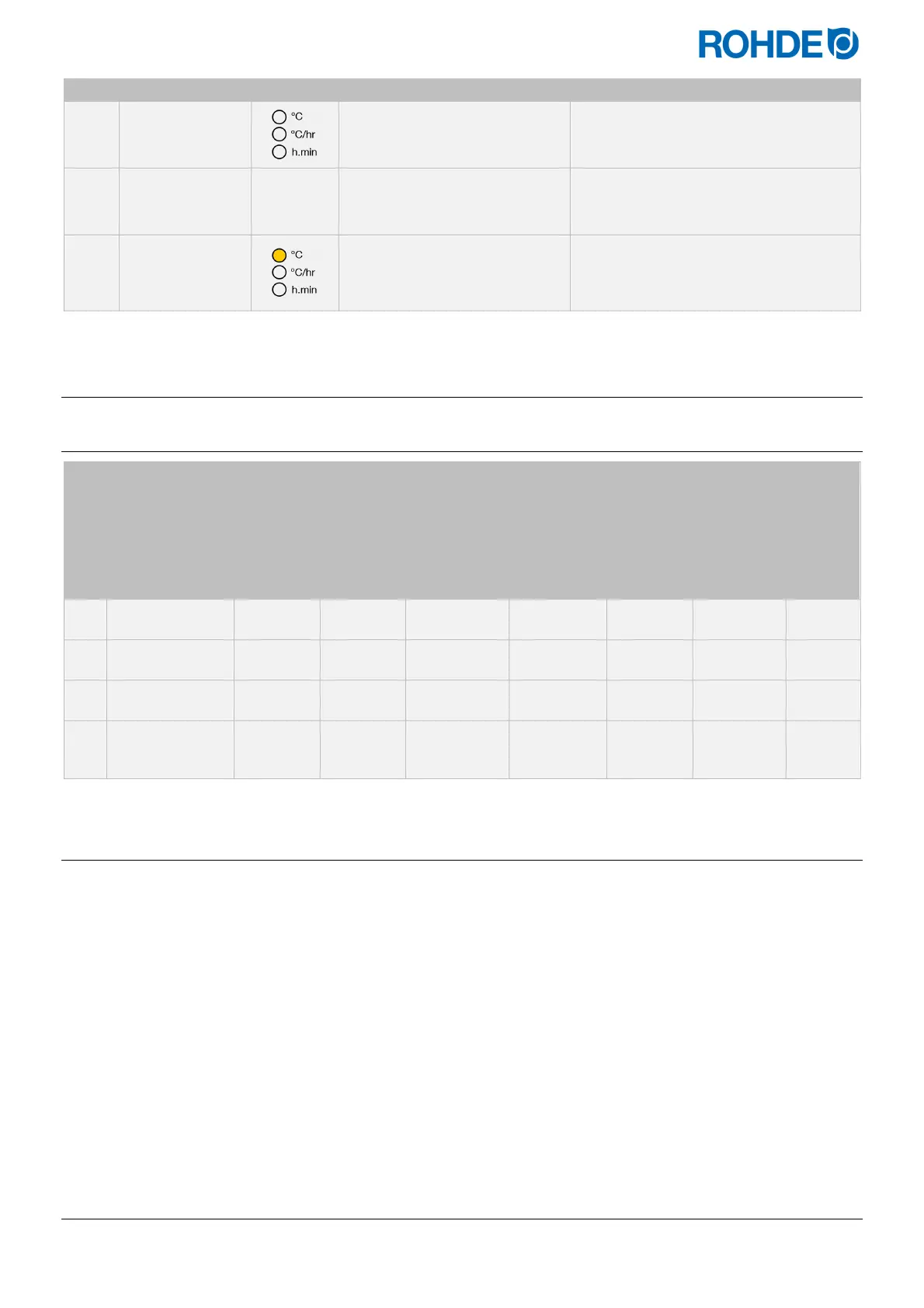

13. Example of a firing program

13.1. Program examples (ceramics)

Program no.

Description

Segment 1

“ Ramp rate”

Segment 1

“ Soak

temperature”

Segment 1

“ Soak period”

Segment 2

“ Ramp rate”

Segment 2

“ Soak

temperature”

Segment 2

“ Soak period”

Segment 3

“ Ramp rate”

1

Initial firing

1050°C

100°C/h 1050°C 00 h:00 min FULL/SKIP 1050°C

01 h:30

min

END

2

Biscuit firing

950°C

60°C/h 600°C 00 h:00 min 100 950°C

00 h:00

min

END

3

Earthenware

1050°C

150°C/h 900°C 00 h:00 min 100 1050°C

00 h:30

min

END

4

High-temperature

stoneware

1250°C

150°C/h 900°C 00 h:00 min 60 1250°C

00 h:05

min

END

13.2. Information on firing programs

The preset controller programs are simple sample programs for biscuit, earthenware and stoneware firing.

These programs must be checked before firing to allow the firing temperature, heating rates and soak times to

be adapted to the materials used.

The variety of ceramic bodies, engobes, glazes and decorative colours as well as different types, sizes and

performances of the kilns used, and individual furniture set assemblies, types and quantities of products to be

fired make it difficult to make generally applicable recommendations.

We advise against using uncontrolled full power heating ramps (“FULL”) to protect heating elements and the kiln

from unnecessary wear and to allow for repeatable firing results.

The preset program no. 1 “Initial firing” is used for:

the initial firing of the kiln after commissioning

after replacing new heating elements (oxidation firing)

the initial firing of new furniture material (stilts and batts)

When using program no. 1 “Initial firing”, the inlet and outlet air openings of the kiln must be open. Please also

consult the kiln instruction manual.

14. Cleaning the control unit

Loading...

Loading...