83

4.2 Inspection/maintenance intervals

4

4.2 Inspection/maintenance intervals

Perform inspection/maintenance periodically, and also before analysis.

WARNING

• RISK OF BURNSDO NOT perform maintenance until the temperature of component you are going to work

on (column oven, injection port, or detector) drops below 40C.

• When using reagents such as organic solvents or acids, work in a well-ventilated area using a drafter or

other ventilation equipment.

ALWAYS wear protective clothing, such as goggles, gloves, and a lab coat.

If reagents get on the skin or in the eyes, flush with copious amounts of water and consult a medical

professional.

CAUTION

• To prevent screws and nuts from burning, DO NOT turn them when the component you are working on is at

high temperature.

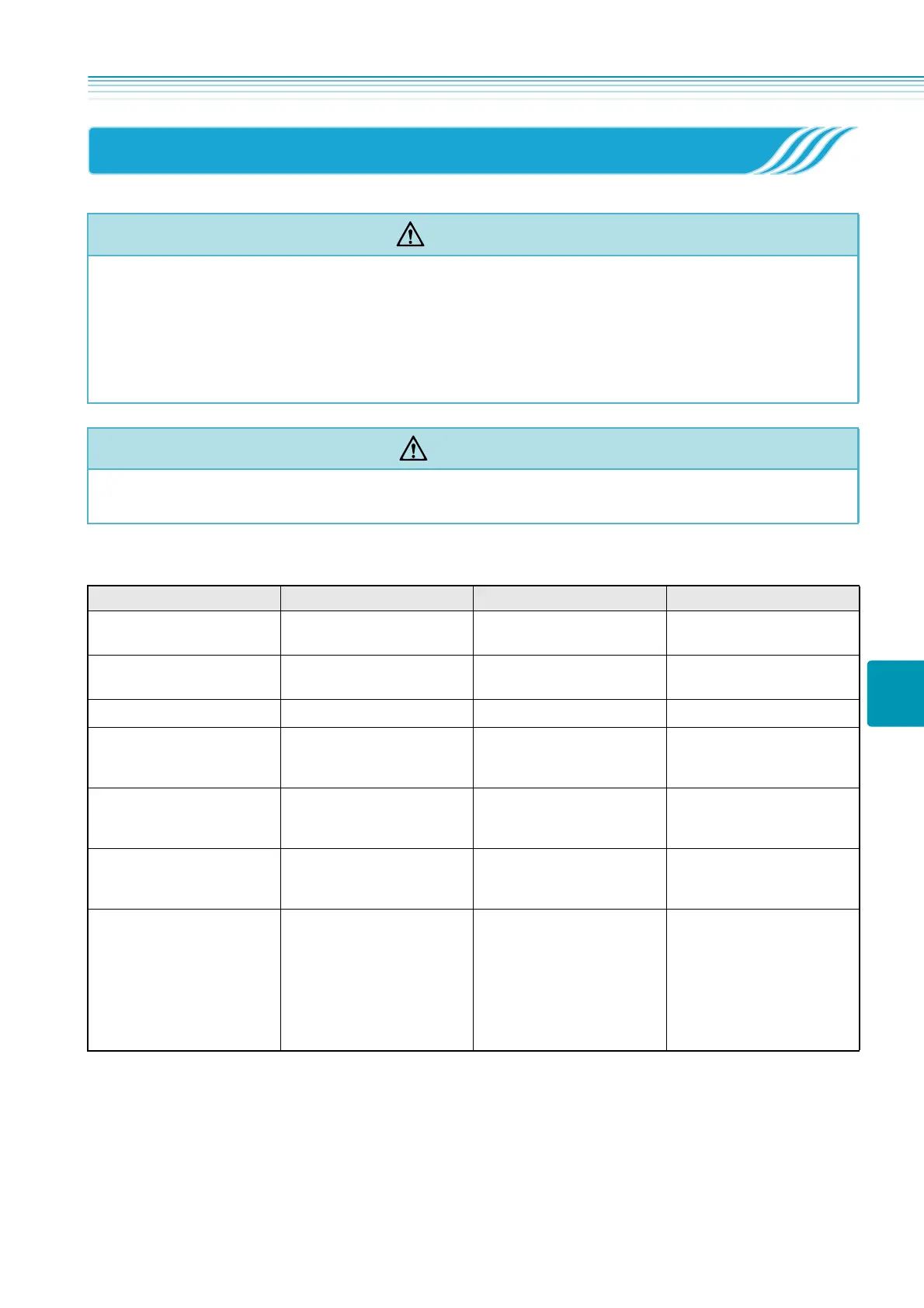

Item Inspection interval Solution Reference

Glass insert Before starting a series of

analysis.

If you find stains or dirt,

cleanse them.

Refer to "4.6 Glass insert" P.

91.

O-ring for glass insert When replacing glass insert. Replace it. Refer to "4.5 O-ring for

glass insert" P. 89.

Septum After 100 injections. Replace it. Refer to "4.4 Septum" P. 87.

Graphite ferrule Each time when installing

columns.

If there is no gap between

back ring and side ring,

replace it.

Refer to "4.7 Graphite

ferrule" P. 94.

Capillary column When using brand-new

columns, or those unused

for long time.

Condition them. Refer to "4.9 Capillary

column" P. 97.

Flow controller split flow line

and septum purge flow line

trap

Each 6 month If there is a blockage,

replace it.

Unit surfaces Each time when using the

GC.

For surface stains, wipe

them with a dry, soft cloth.

For heavy stains, dip cloth

with mild detergent water,

twist well, and wipe with it.

DO NOT use organic

solvent to avoid damaging

plastic or painted surfaces.

Loading...

Loading...