4.10 Flow controller (SPL, WBI only)

100

Trap replacement

Replace traps by the following procedures.

(1)

Stop carrier gas supply.

(2)

Remove INJ/DET cover.

(3)

To avoid error, replace the traps one by one.

(4)

Remove the blind from a new trap.

This blind has been used for sealing the inside of

the trap. You don't need the blind any more.

(5)

Install the new trap.

The tubing codes are as follows.

S ............ Split flow line

P ............ Septum purge flow line

C ............ Carrier gas inlet flow line

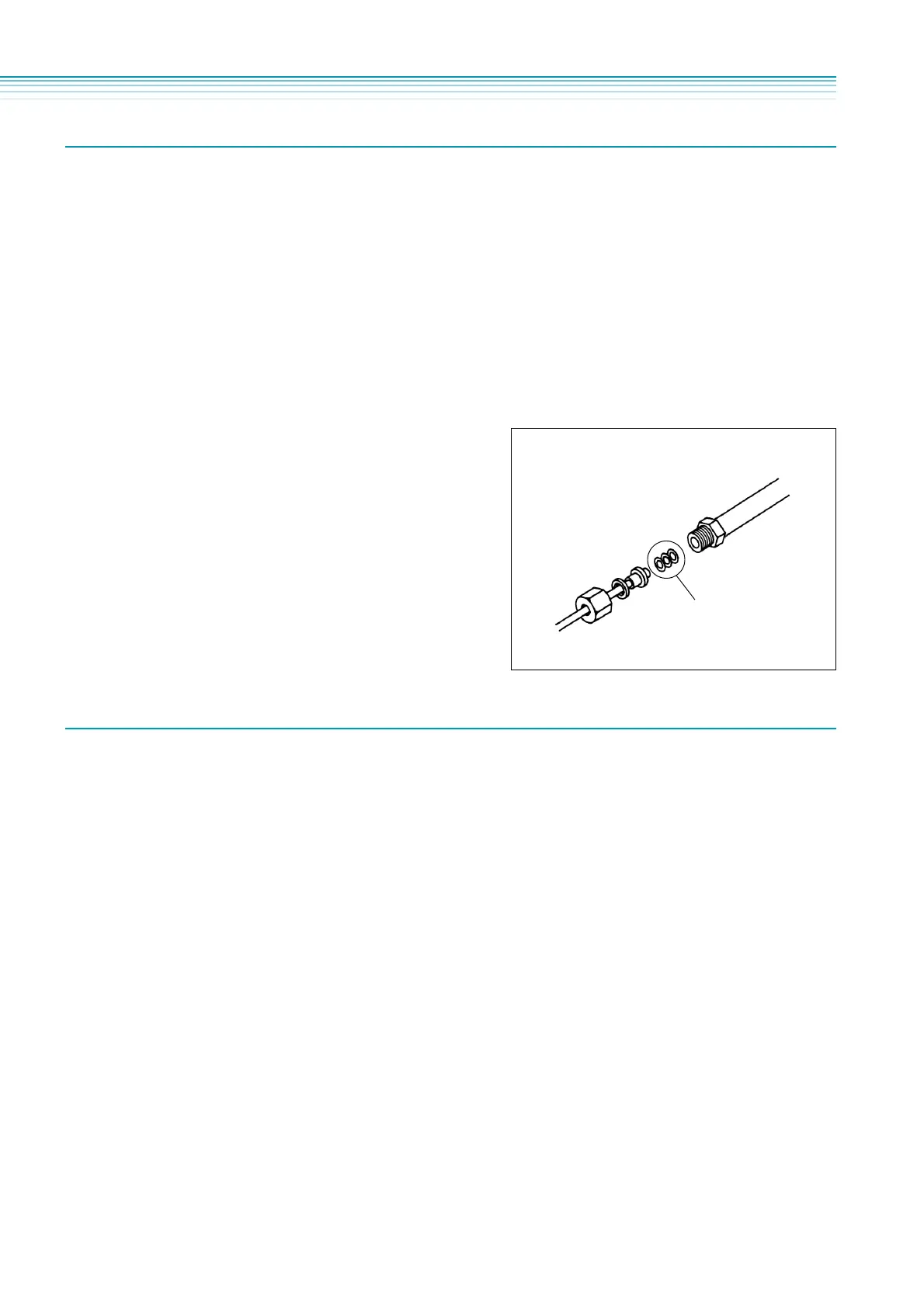

DO NOT forget to insert a couple of aluminum

gaskets between G-type joints.

Conditioning molecular sieve filter

To condition molecular sieve filter, use the following procedures.

(1)

Stop carrier gas supply.

(2)

Remove INJ/DET cover.

(3)

Remove molecular sieve filter.

(4)

Condition the filter to the following conditions.

Flow direction of N

2

or He gas

Opposite direction of the GC normal operation

Gas flow rate...........10 to 20 ml/min

Temperature............300C

Time ........................3 to 4 hours

(5)

After conditioning, immediately reinstall the

molecular sieve filter so that the filter does not get

contaminated.

G-type joint connection

GM joint

Column aluminum

gaskets (2 to 3 pcs)

GF joint

Loading...

Loading...