4.7 Graphite ferrule

94

4.7 Graphite ferrule

If you are using packed column

Purpose of inspection

(1)

Checking for carrier gas leaks

If carrier gas leaks due to graphite deterioration, it causes poor reproducibility.

Check to see if graphite has deteriorated or not. If it has, replace with a new graphite ferrule.

(2)

Checking if graphite impurity is the cause of ghost peaks

Generally speaking, if ghost peaks appear in your analysis, there can be impurities in the column inlet

connection.

If your baseline drift is quite large even though using a sufficiently aged column, there can be impurities

in the column outlet connection.

In such cases, condition graphite ferrule by the following procedures.

Conditioning graphite ferrule

If the graphite impurity is the cause of ghost peaks, condition graphite ferrule by this procedure. (Perform

this just before you start analyzing. If you leave graphite ferrule for a while after conditioning, it can absorb

impurities again.)

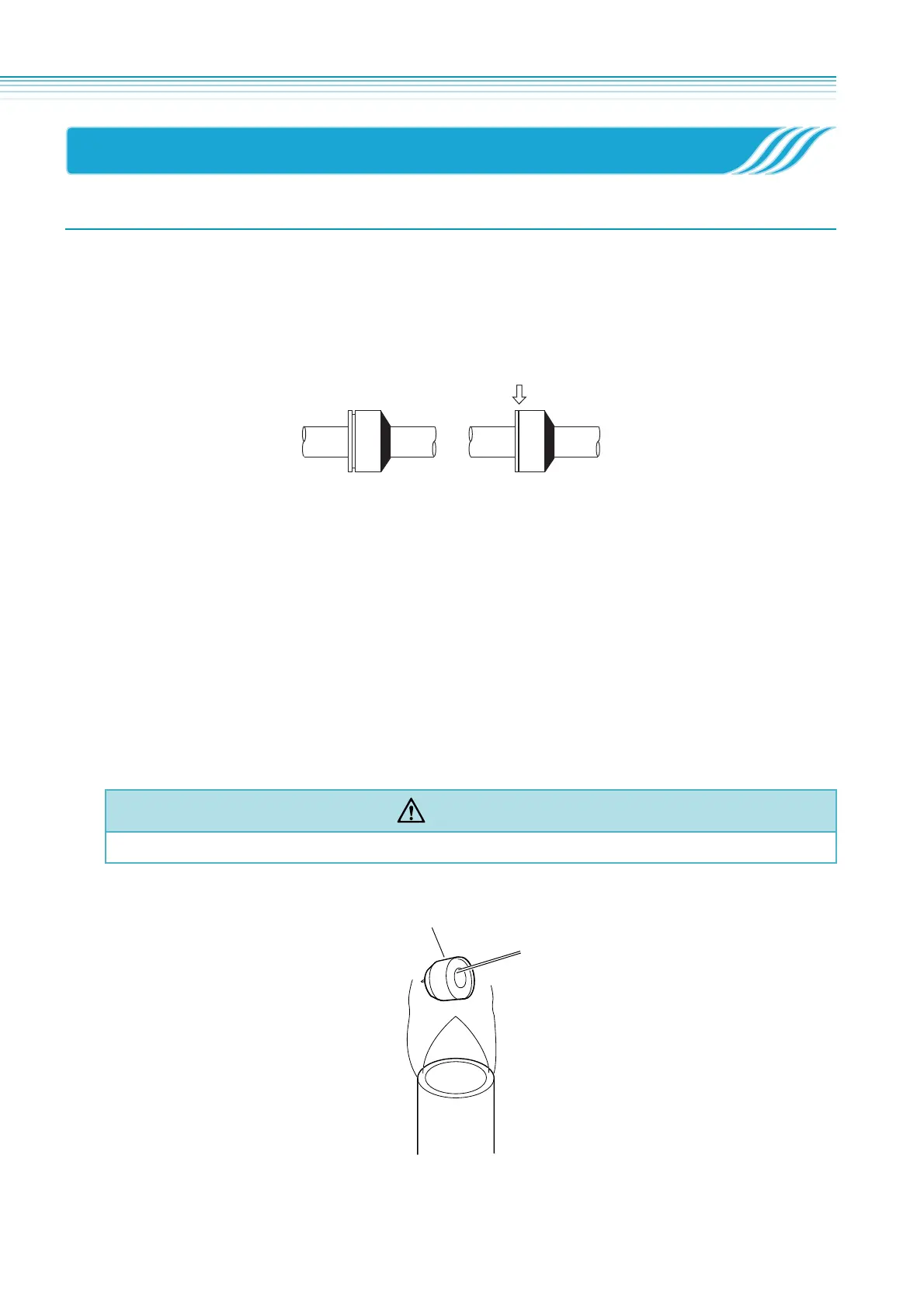

Use gas burner. Put graphite ferrule into the blue flame, and heat it for 1 to 2 sec. after graphite turns red.

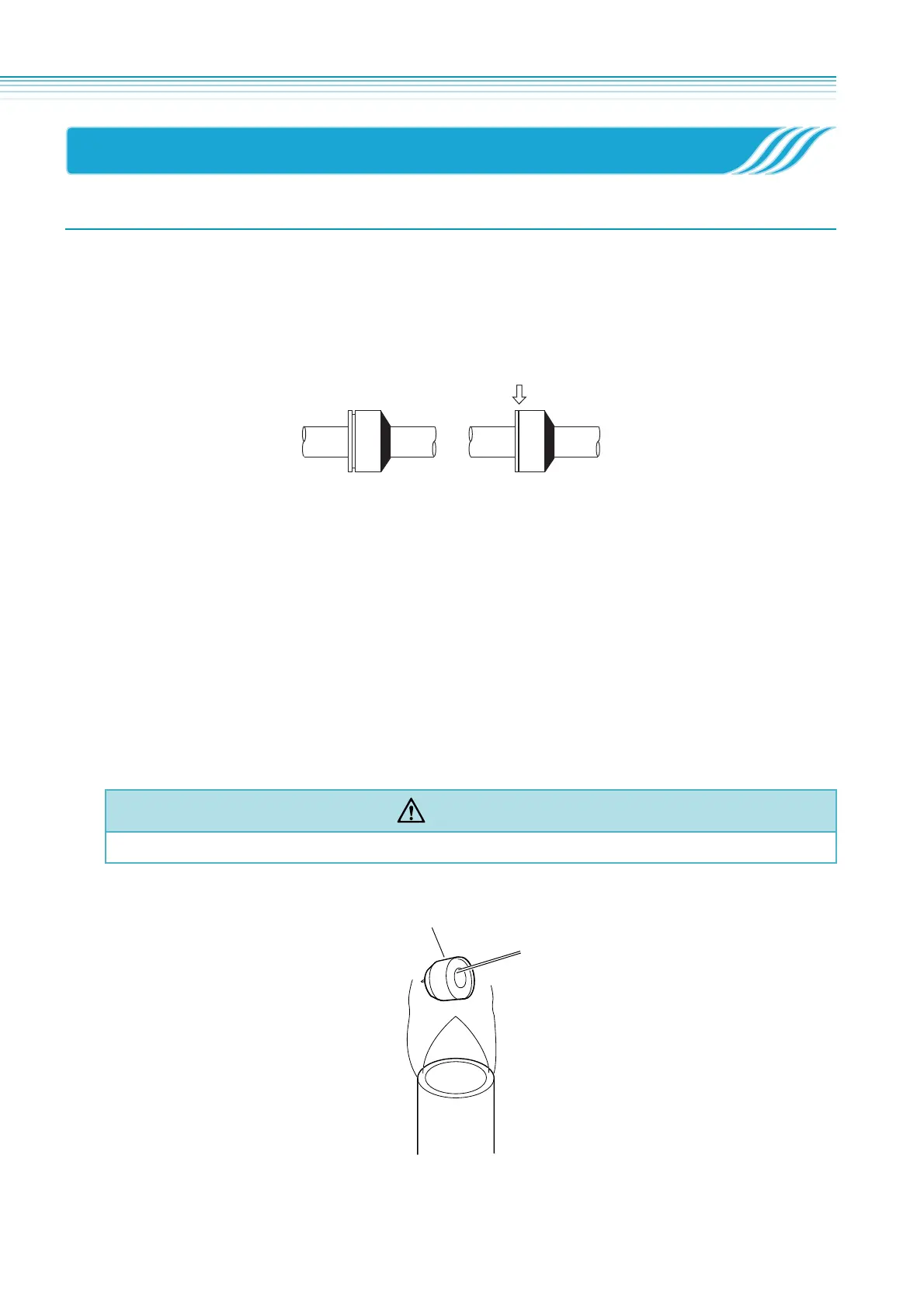

Indicates deterioration (no gap)

New graphite ferrule Graphite ferrule to be replaced

CAUTION

Hold graphite ferrule in such a way as to avoid burns.

Loading...

Loading...