117

5.1 Trouble shooting

5

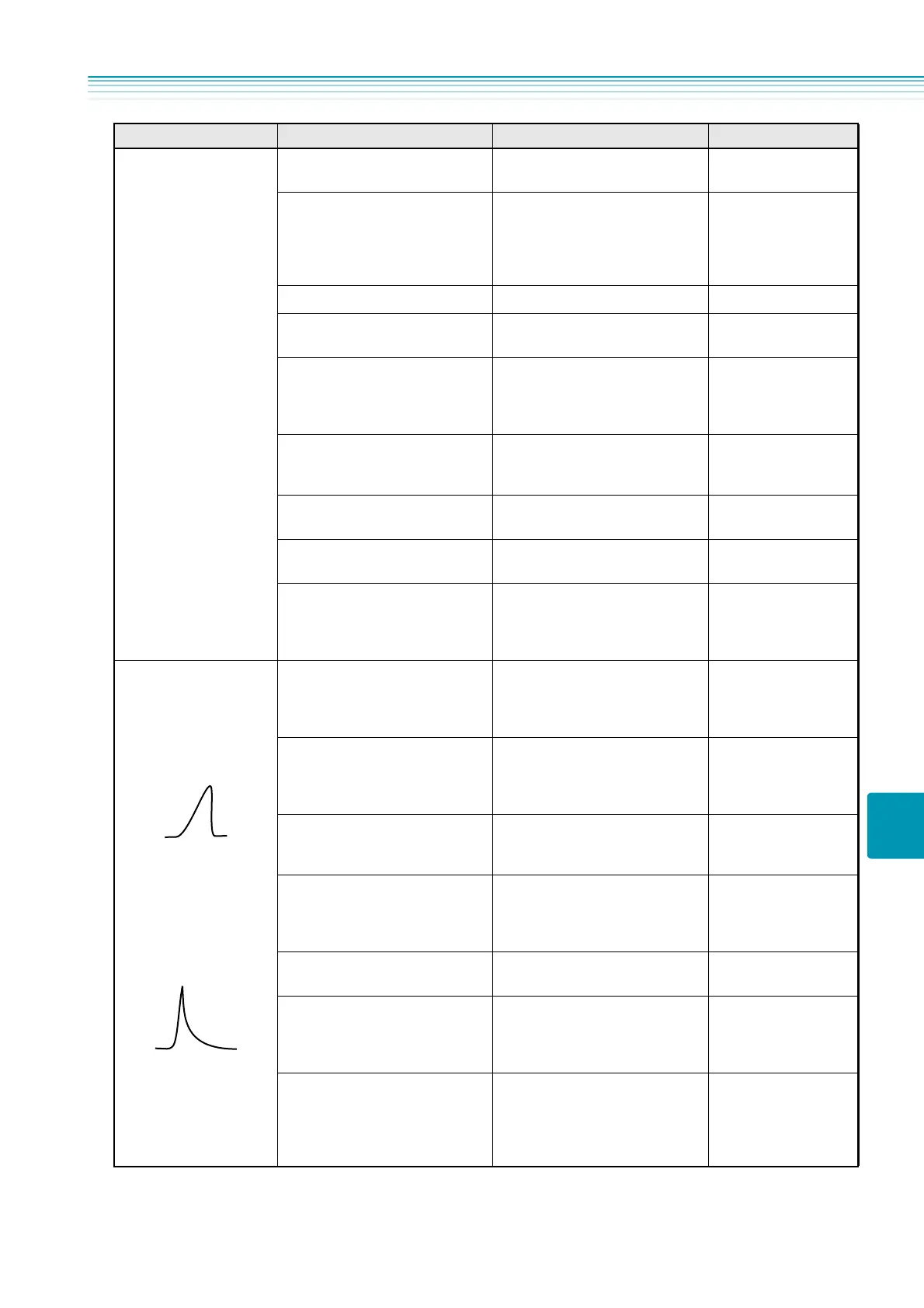

Presence of ghost

peaks

Septum purge is not being

supplied.

Supply septum purge.

Peaks of previous analysis

appear.

Increase column oven

temperature to the analysis

maximum temperature to

eliminate the sample remaining

inside of column.

Sample is contaminated. Prepare new sample.

Microsyringe is dirty. Cleanse the microsyringe, or

replace it with a new one.

Carrier gas purity is low. Replace carrier gas with one of

higher purity. Provide molecular

sieve filter in carrier gas flow

line.

Substances of high boiling point

accumulated at column inlet

end are flowing out.

Condition columns.

Injection port is dirty. Clean or replace the glass

insert.

Refer to "4.6 Glass

insert" P. 91.

Tubing and pressure governors

are contaminated with oil, etc.

Replace tubing, pressure

regulator, etc. with clean ones.

Septum fragments are present

inside of glass inserts or

columns.

Remove the fragments.

Cleanse or replace the glass

inserts. Break off the tip of

capillary column.

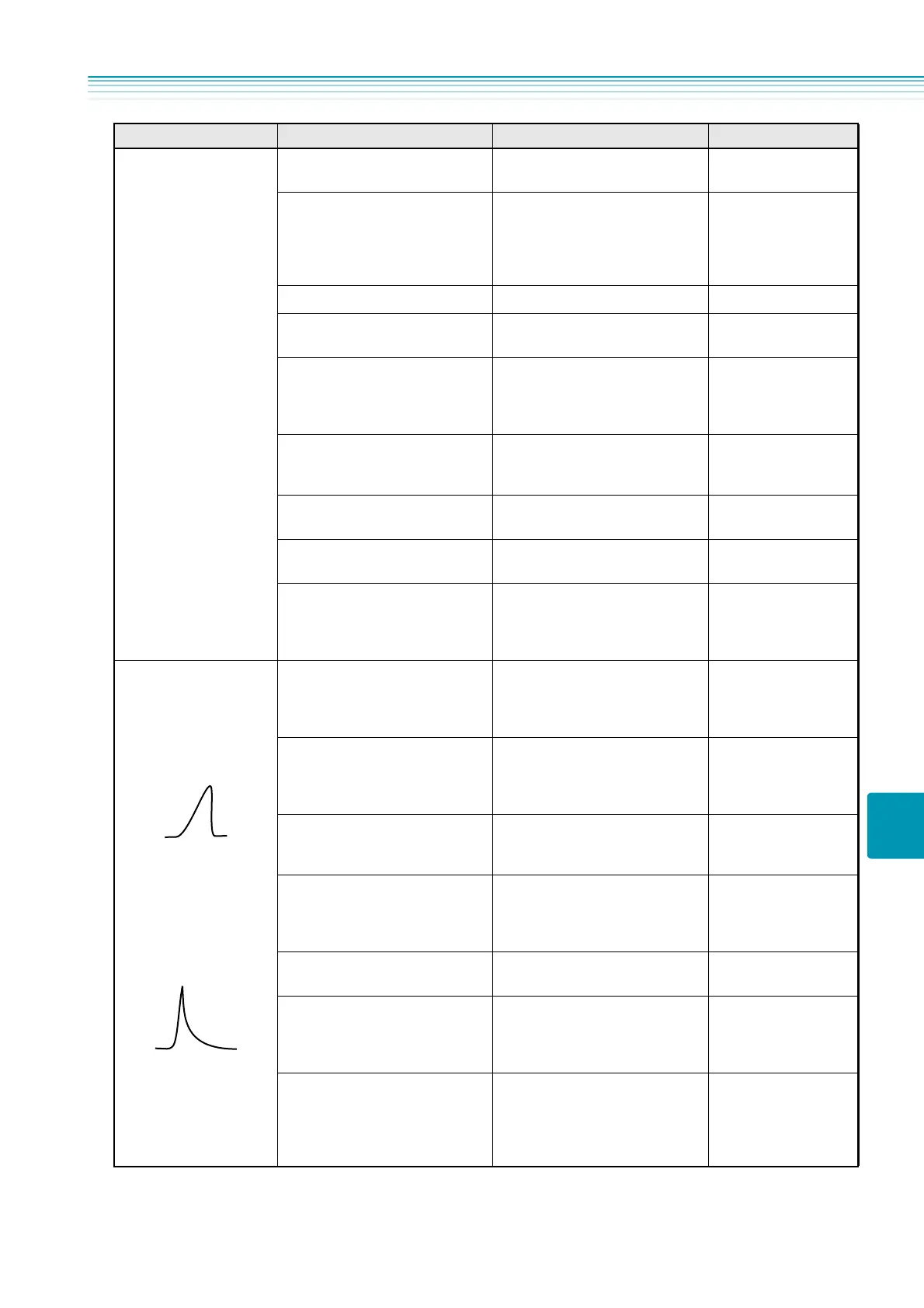

Abnormal peak shape

(e.g. asymmetrical

shape)

[Leading]

The peak arises slowly.

The peak front is

larger.

[Tailing]

It takes very long time

for a peak to dissolve

to the baseline level.

The peak tail is

dragged out.

(In case of Leading) the column

is overloaded.

Dilute sample.

Decrease injection volume, or

increase split ratio.

Change the film to thicker one.

(Divided peak top, leading, or

tailing) Multiple peaks are not

completely separated and

merged into one peak.

Decrease column oven

temperature.

Replace columns to obtain

better separation.

(Leading, or tailing)

Injection port temperature is

low.

Increase injection port

temperature.

(Tailing)

Columns are contaminated.

Condition columns. Refer to "4.8 Packed

column" P. 96 and

"4.9 Capillary

column" P. 97.

(Tailing)

Glass insert is damaged.

Replace the glass insert. Refer to"4.6 Glass

insert" P. 91.

(Tailing)

Septum purge is not supplied,

or is too low.

Supply septum purge.

Increase septum purge flow

rate.

Refer to "3.3

Analysis using

capillary column" P.

49.

(Tailing)

Septum fragments are present

inside glass insert or column.

Remove the fragments.

Cleanse or replace the glass

inserts.

Break off the tip of capillary

column.

Problem Possible cause Solution Reference

Loading...

Loading...