7UT51 v3

Thermal Overload Protection (49-1, 49-2)

9

PRIM-2330C 109

Example:

If the short-time overload capacity is stated

for a duration of 1 s, then that short-term

current is inserted into the above formula.

Note:

The result becomes more inaccurate the

longer the stated duration of the current

becomes.

The single-body thermal body model used by the relay

is appropriate for small continuous overloads (up to

approximately 1.2 times the rated current). For larger

continuous overloads, it is sufficient to set a slightly

shorter time constant which considers the faster

warm-up of the winding as compared to the iron.

9.3.3 Warning Alarm Levels

The element can generate a warning-alarm event prior

to the pickup event. The alarm event can be

configured to trip and output contacts to take

corrective actions (load shedding, activation of cooling

equipment, etc.).

Two types of warning exist; one based on temperature

rise, and the other based directly on the overload

current.

The warning based on temperature rise occurs when

the calculated temperature rise reaches a specified

percentage of the trip value. Of course, the warning

level should be less than 100% of the trip-level

temperature rise (Q

trip

), and higher than the

temperature at the allowed maximum continuous

overload current (Q

cont

), which can be calculated from

the k factor:

(9.5)

For example, if k is 1.1, then 1/k

2

is 83%, so Q

warn

should be more than 83% (the allowed continuous

overload current) and less than 100% (the trip-level

temperature rise).

The warning based on the overload current occurs

when the measured current reaches a specified

multiple of the rated current:

9.3.4 Temperature Rise

Calculation Method

The calculated temperature rise may be different for

each phase of the protected winding. Address 2406

(or 2506) specifies whether to use as the value of Q

the maximum of the three temperature values (one for

each phase current), the mean temperature value, or

the temperature rise calculated based on the largest

phase current.

2403 49 Tconst 1

2503 49 Tconst 2

Thermal overload time constant τ

Range: 1.0

–

999.9 minutes

Default: 100.0 minutes

τ

1

60

------

⎝⎠

⎛⎞

permissible 1s current

continuously permissible current

------------------------------------------------------------------------------

⎝⎠

⎛⎞

2

×=

1

k

2

-----

Θ

cont

Θ

trip

-------------

Θ

warn

Θ

trip

---------------

Θ

trip

Θ

trip

------------

<< 100%==

2404 49

Θ

ΘΘ

Θ

ALRM1

2504 49

Θ

ΘΘ

Θ

ALRM2

Temperature rise that will cause a warning

alarm (specified as a percentage of the

temperature rise that will cause a pickup).

Range: 50

–

100% of pickup temperature rise

Default: 90%

2405 ALRM1

2505 ALRM2

Warning

-

level continuous thermal current,

specified as a multiple or fraction of I

N

.

Range: 0.10

–

4.00 I/I

n

Default: 1.10 I

n

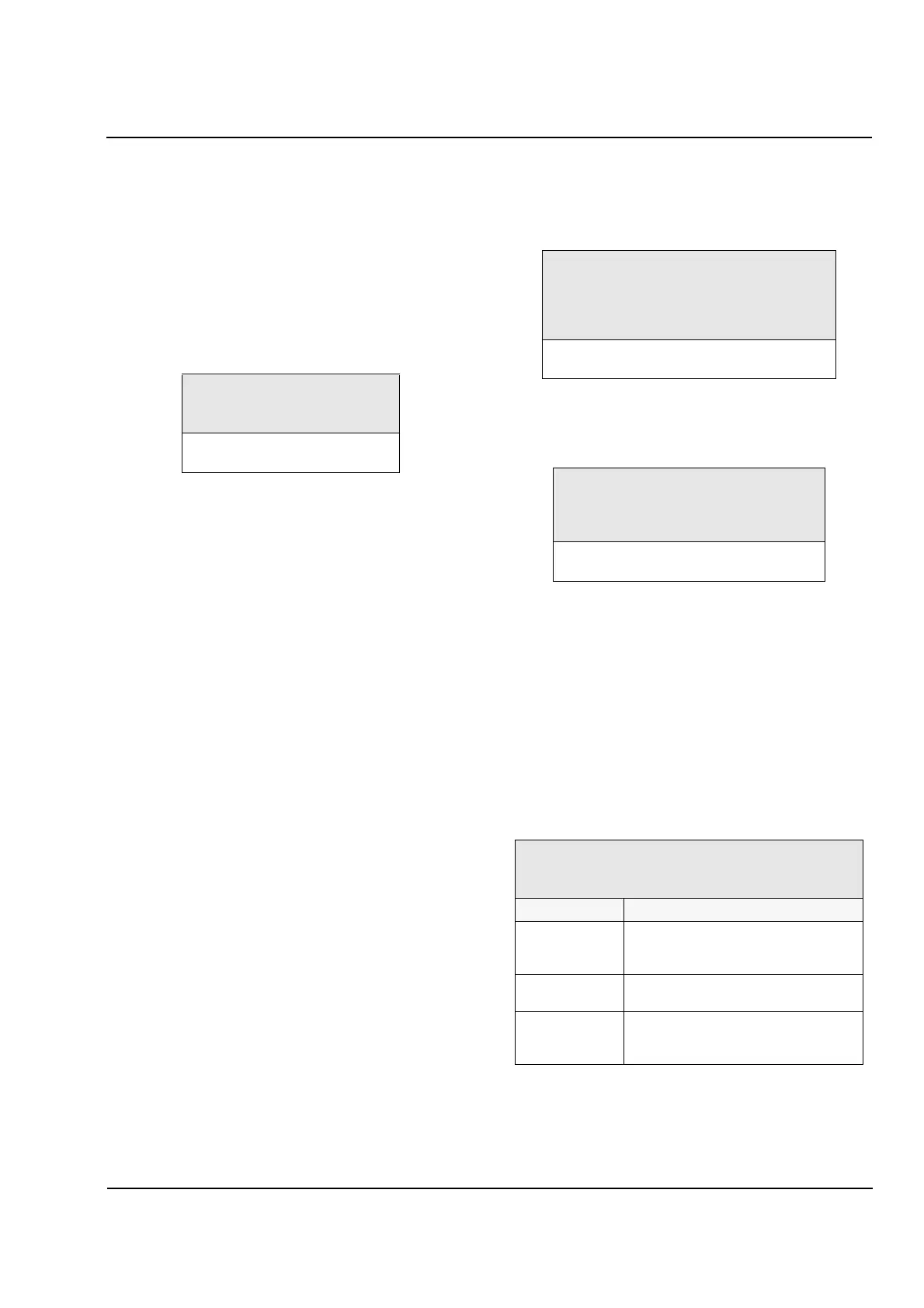

2406 TEMP METH1

2506 TEMP METH2

Method for calculation of instantaneous temperature Θ.

Option Description

Θ max Calculate the temperature for each

phase current, then use the maximum

(default).

Average Θ Calculate the temperature for each

phase current, then use the average.

Θ at Imax Identify the largest phase current,

then calculate and use its

temperature.

Loading...

Loading...