7UT51 v3

Bench Testing

16

PRIM-2330C 173

16.7 Thermal Overload

Protection Testing

Two thermal overload protection functions are

available, each of which can be assigned to any

desired side of the protected object or to the virtual

object. The relay is programmed with the side of the

protected object of the first overload protection

(Address 7824) and the second overload protection

(Address 7825). Each overload protection must be

parameterized as operative,

On

, in addresses 2401

and 2501.

Testing of 49-1 and 49-2 may cause operations of 87,

87HS, 50/51, and 50HS. If this occurs, set to

Off

to

disable the differential elements and backup

overcurrent elements.

Note:

After testing 49-1 and 49-2, these addresses

must be reset to the desired values.

The basis current for the detection of overload is the

rated current of the protected object.

For use as transformer protection, the basis current is

the rated current of the protected transformer winding.

If the windings have different MVA ratings, then the

overload function always refers to the rated current of

the respective winding. It is assumed that the

transformer data for each winding have been correctly

parameterized.

For use as generator or motor protection, overload

protection is based on the rated current of the

protected machine which is derived from the data

entered in Address Block 1200.

For use as branch protection, overload protection is

based on the rated current of the branch point entered

in Address Block 1300.

If the overload protection is used for a virtual object,

overload is based on the rated current of the virtual

object entered in Address Block 1400.

Address 2406 is important for testing 49-1. If

Address 2406 = Average , this procedure requires

that a single current source be connected to inject

current in all three phases associated with the winding

or object. If Address 2406 = [ MAX] or [ @ Imax],

then current injection into any one phase is sufficient.

The same comments for Address 2406 apply to

Address 2506, which is associated with 49-2.

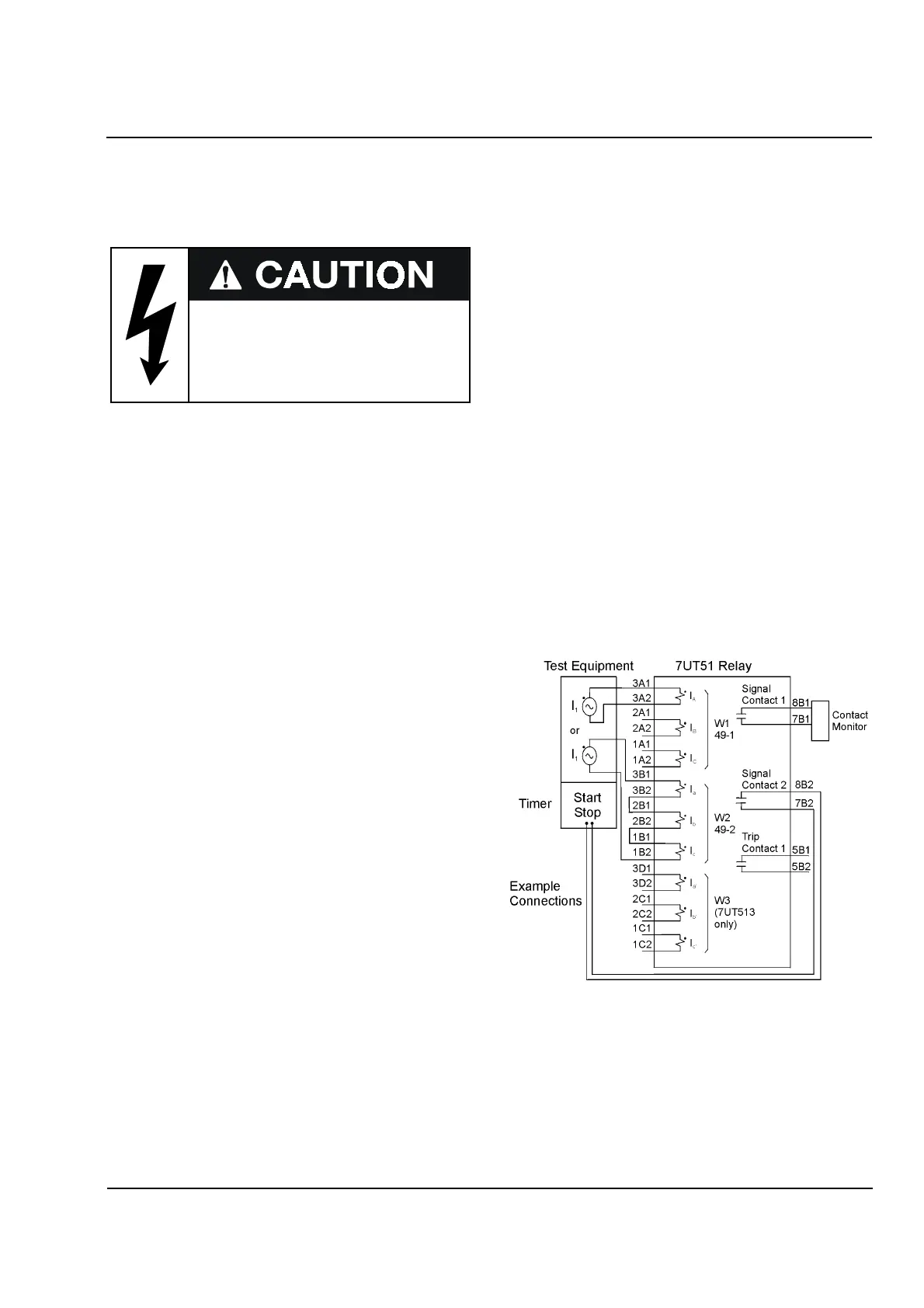

The same 7UT51 connections can be used for all of

the 49 tests. Figure 16.13 shows the connections for

the following example. Element 49-1 is protecting

Winding 1 using either the maximum calculated

temperature for each phase current

(Address 2406 = MAX) or the calculated

temperature based on the highest phase current

(Address 2406 = @ Imax). Element 49-2 is

protecting Winding 2 using the average of the

calculated temperatures of the phases.

For the example, this procedure requires current be

injected in all three phases of Winding 2 to test 49-2.

Current injection for Winding 1 can be either

single-phase or include all three phases (single-phase

is shown for simplicity).

Figure 16.13

Test Connections for Testing 49

-

1 and 49

-

2

First identify the applicable winding for current

injection. Then, based on Address 2406 or

Address 2506, connect the winding phases for either

single-phase or three phase current injection.

Test currents larger than four (4)

time In or 15A (Sensitive input) may

overload and damage the relay if

applied continuously.

Observe a cooling down period!

Θ

ΘΘ

Θ

Θ

Loading...

Loading...