Functions

8.2 Data Sets

Control Units CU240S

Operating Instructions, 11/2006, A5E00766042B AA

8-9

(e.g. the higher-level control unit fails). A typical example in this case is a mixer, which may

come to an uncontrolled stop when the control fails.

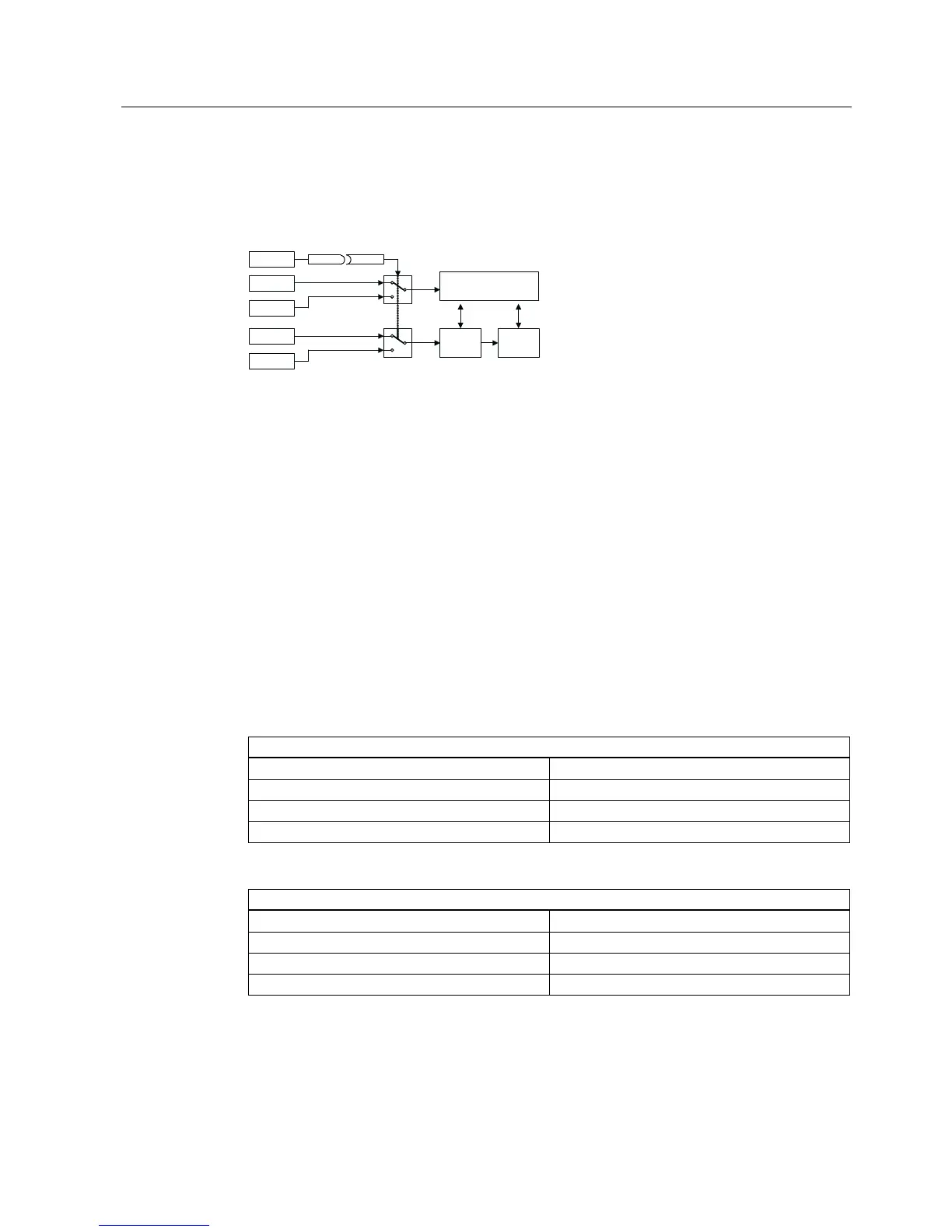

P0700[0] = 2

P0810 = 722.3

0

1

0

1

P0700[1] = 1

P1000[0] = 2

P1000[1] = 1

DI3

OP

&RPPDQGVRXUFH 7HUPLQDO!23

6HWSRLQWIUHTXHQF\VRXUFH $,!023

Motor

control

Terminals

AI

MOP

Sequence control

Setpoint

channel

Figure 8-5 Changing-over between the control and setpoint source

CDS0: Command source via terminals and setpoint source via analog input (AI)

CDS1: Command source via OP and setpoint source via MOP

CDS changeover is realized using digital input 3 (DI3)

Commissioningsteps:

1. Carry-out commissioning for CDS0 (P0700[0] = 2 and P1000[0] = 2)

2. Connect P0810 (P0811 if required) to the CDS changeover source

(P0704[0] = 99, P0810 = 722.3)

3. Copy from CDS0 to CDS1 (P0809[0] = 0, P0809[1] = 1, P0809[2] = 1)

4. Adapt CDS1 parameters (P0700[1] = 1 and P1000[1] = 1)

Drive data set

The drive data set (DDS) contains various setting parameters which are of significance for

the open-loop and closed-loop control of a motor:

Drive and encoder data, e.g.

Select motor type P0300

Rated motor voltage P0304

Main inductance P0360

Select encoder type P0400

Various closed-loop control parameters, e.g.

Fixed frequency 1 P1001

Min. frequency P1080

Ramp-up time P1120

Control mode P1300

Loading...

Loading...