246/267

Building Technologies Basic documentation LMV37.4... CC1P7546en

29 Error code list (all LMV2 types / LMV3 types) 17.12.2018

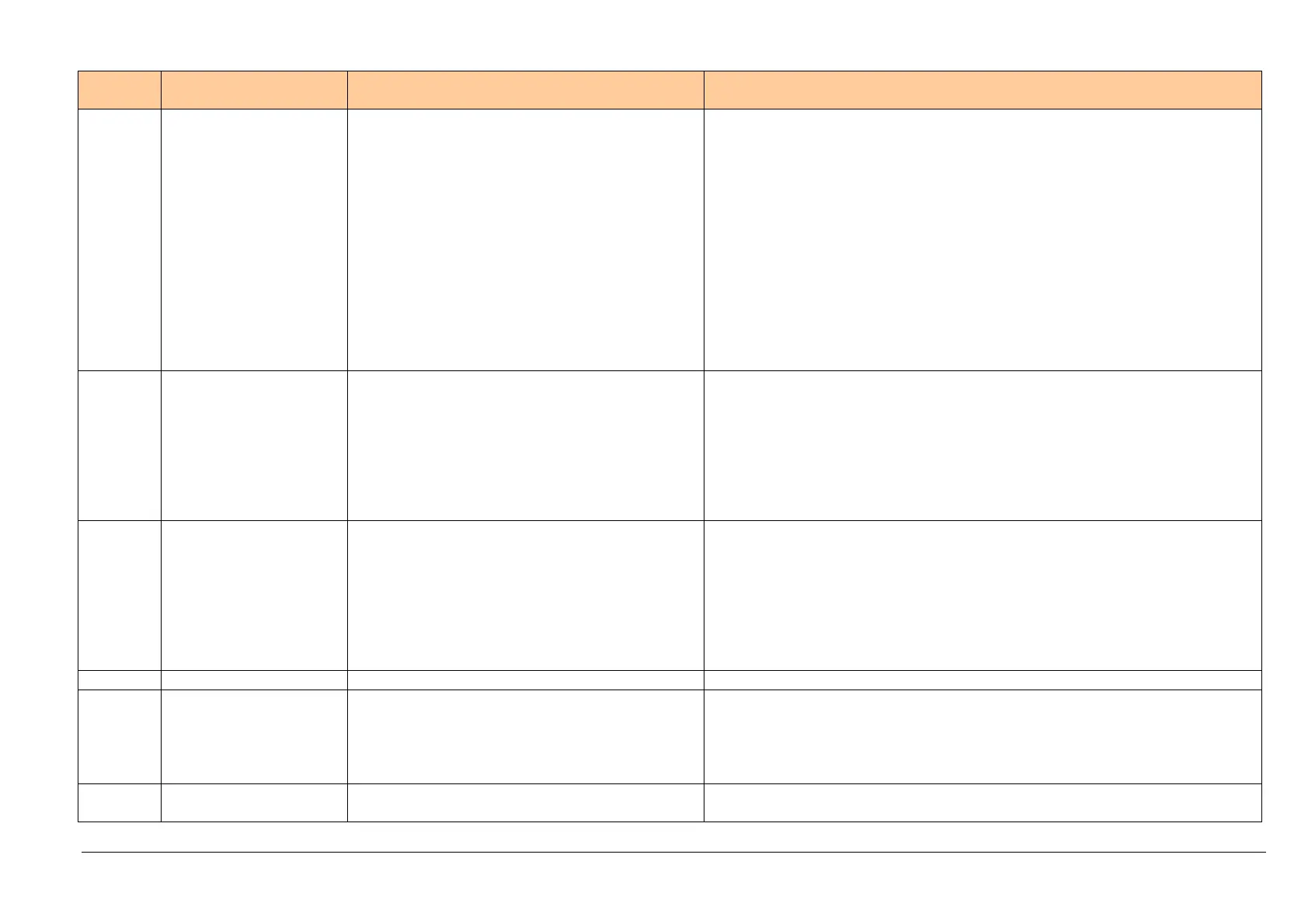

Error

code

Diagnostic code Meaning for the LMV37.4 Recommended measures or causes

Valency 1

(parameter 544).

1. Modulating operating ramp 32 seconds

Curve slope max. 10% for LMV37.4 ramp of 20 seconds (20% for 10 seconds or 40% for 5

seconds)

2. Modulating operating ramp 48 seconds

Curve slope max. 10% for LMV37.4 ramp of 30 seconds (20% for 15 seconds or 30% for 10

seconds)

3. Modulating operating ramp 64 seconds

Curve slope max. 10% for LMV37.4 ramp of 40 seconds (20% for 20 seconds or 40% for 10

seconds)

→ Between the ignition point (P0) and the low-fire point (P1), the speed change in modulating

mode may be a maximum of 40%, independent of the LMV37.4 ramp.

4. Setting of the VSD ramp must be about 20% shorter than the ramps in the LMV37.4

(parameters 522 and 523)

Bit 1

Valency 2..3

Fuel actuator: Curve too steep in terms of ramp rate

Check position differential between the curvepoints and the modulating operating ramp setting

(parameter 544).

1. Modulating operating ramp 32 seconds

The slope of the curve may be a maximum position change of 31° (15° for SQM33.6 and 9° for

SQM33.7) between 2 curve points in modulating mode.

2. Modulating operating ramp 64 seconds

The slope of the curve may be a maximum position change of 62° (30° for SQM33.6 and 18°

for SQM33.7) between 2 curve points in modulating mode.

Bit 2

Valency 4..7

Air actuator: Curve too steep in terms of ramp rate

Check position differential between the curvepoints and the modulating operating ramp setting

(parameter 544).

1. Modulating operating ramp 32 seconds

The slope of the curve may be a maximum position change of 31° (15° for SQM33.6 and 9° for

SQM33.7) between 2 curve points in modulating mode.

2. Modulating operating ramp 64 seconds

The slope of the curve may be a maximum position change of 62° (30° for SQM33.6 and 18°

for SQM33.7) between 2 curve points in modulating mode.

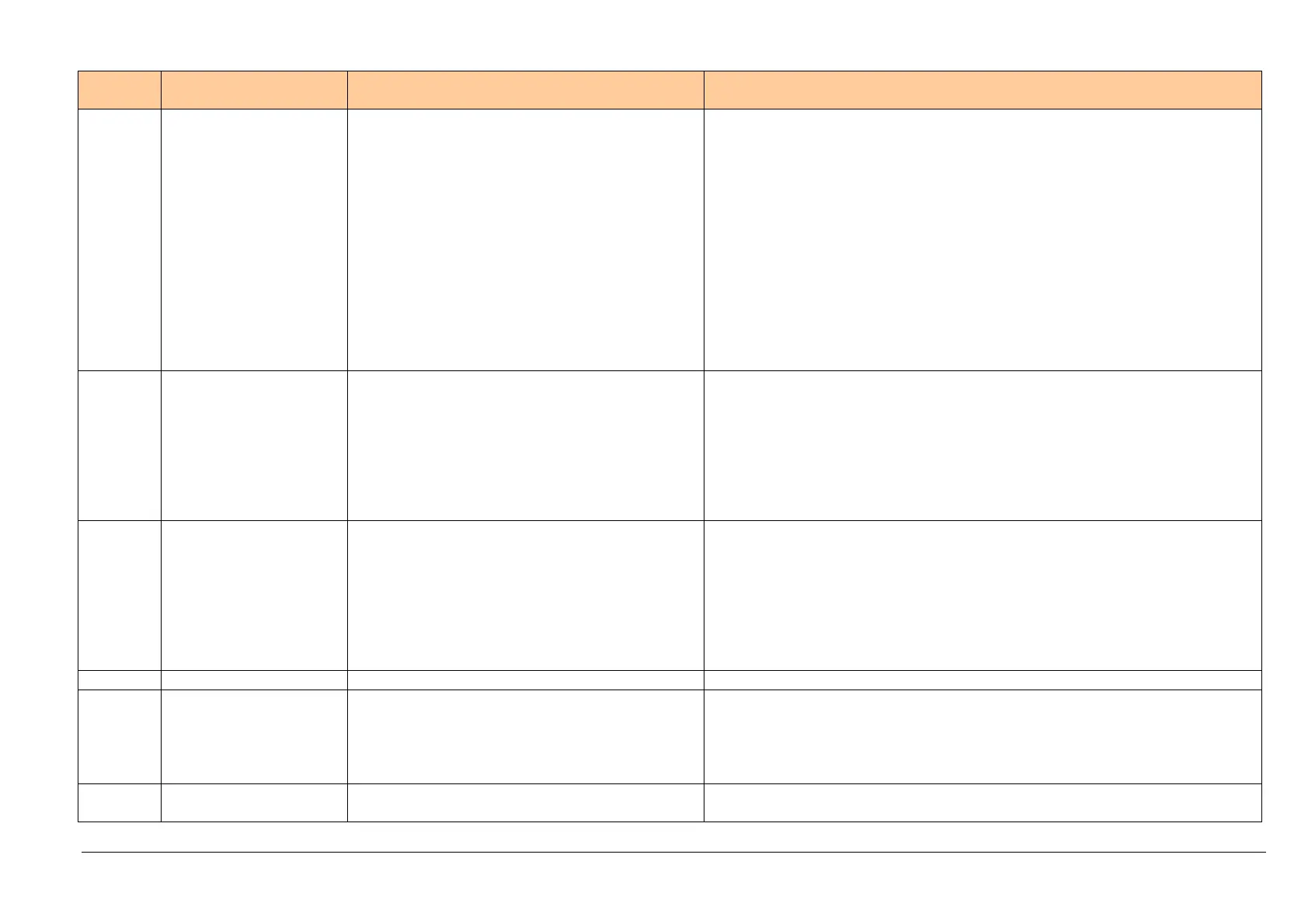

85 # Referencing error ones actuators

0 Referencing error of fuel actuator

Referencing of fuel actuator not successful.

Reference point could not be reached.

1. Check the setting of the actuator type (parameter 613.0 or 614)

2. Check to see if actuators have been mixed up

3. Check to see if actuator is locked or overloaded

1 Referencing error of air actuator

Referencing of air actuator not successful.

Reference point could not be reached.

Loading...

Loading...