247/267

Building Technologies Basic documentation LMV37.4... CC1P7546en

29 Error code list (all LMV2 types / LMV3 types) 17.12.2018

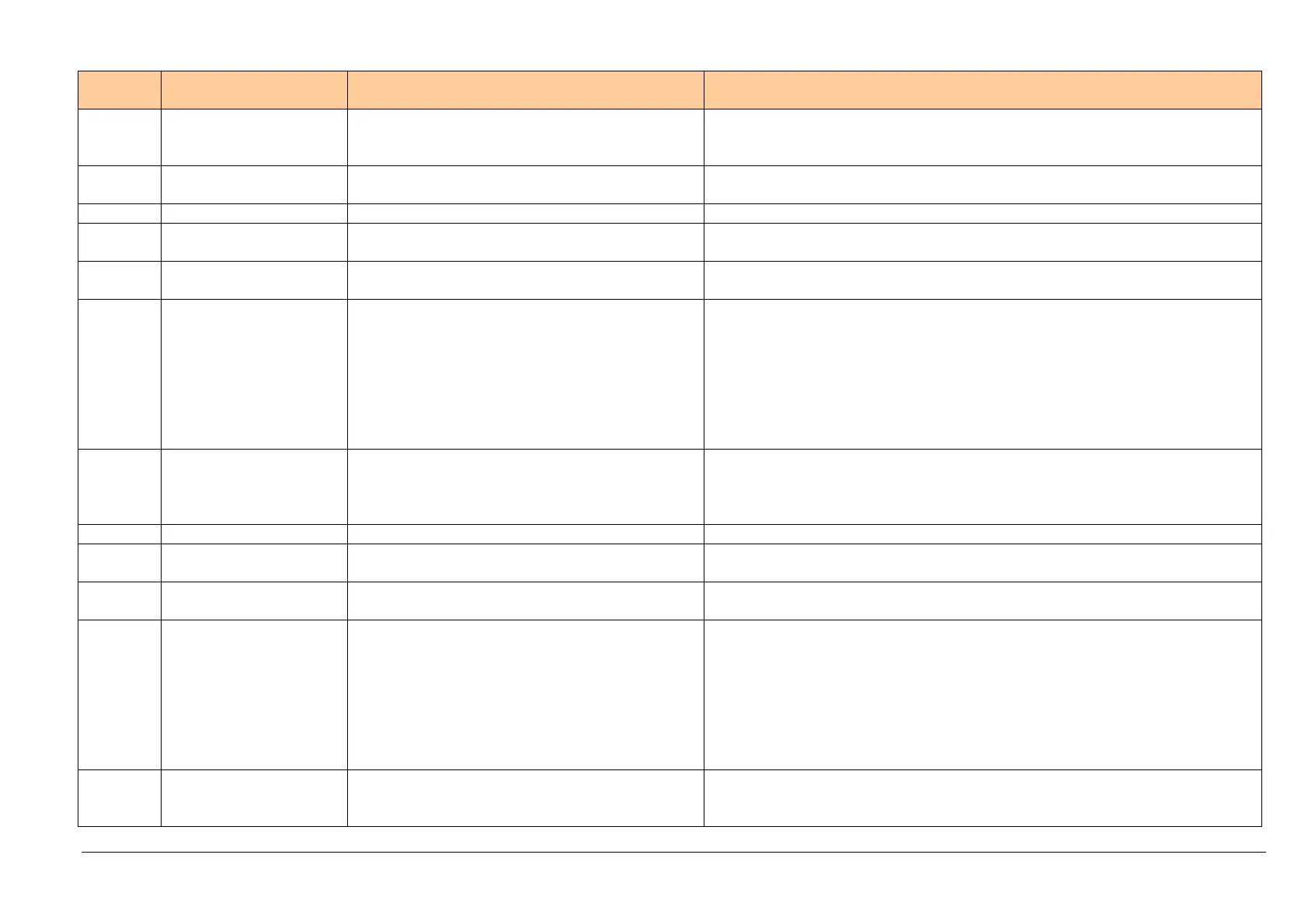

Error

code

Diagnostic code Meaning for the LMV37.4 Recommended measures or causes

1. Check the setting of the actuator type (parameter 613.1)

2. Check to see if actuators have been mixed up

3. Check to see if actuator is locked or overloaded

Bit 7

Valency

128

Referencing error due to parameter change

Parameterization of an actuator (e.g. the reference position) has been changed.

To trigger new referencing, this error is set

86 # Error fuel actuator

0 Position error

Target position could not be reached within the required tolerance band.

Check to see if actuator is locked or overloaded.

Bit 0

Valency 1

Line interruption

Line interruption

detected at actuator’s terminals.

Check wiring (voltage X54 across pin 5 or 6 and pin 2 >0.5 V).

Bit 3

Valency

8

Curve too steep in terms of ramp rate

Check position differential between the curvepoints and the modulating operating ramp setting

(parameter 544).

1. Modulating operating ramp 32 seconds

The slope of the curve may be a maximum position change of 31° (15° for SQM33.6 and 9° for

SQM33.7) between 2 curve points in modulating mode.

2. Modulating operating ramp 64 seconds

The slope of the curve may be a maximum position change of 62° (30° for SQM33.6 and 18°

for SQM33.7) between 2 curve points in modulating mode.

Bit 4

Valency

16

Step deviation in comparison with last referencing

Actuator was overloaded or mechanically twisted.

1. Check the setting of the actuator type (parameter 613.0 or 614)

2. Check to see if the actuator is blocked somewhere along its working range.

3. Check to see if the torque is sufficient for the application.

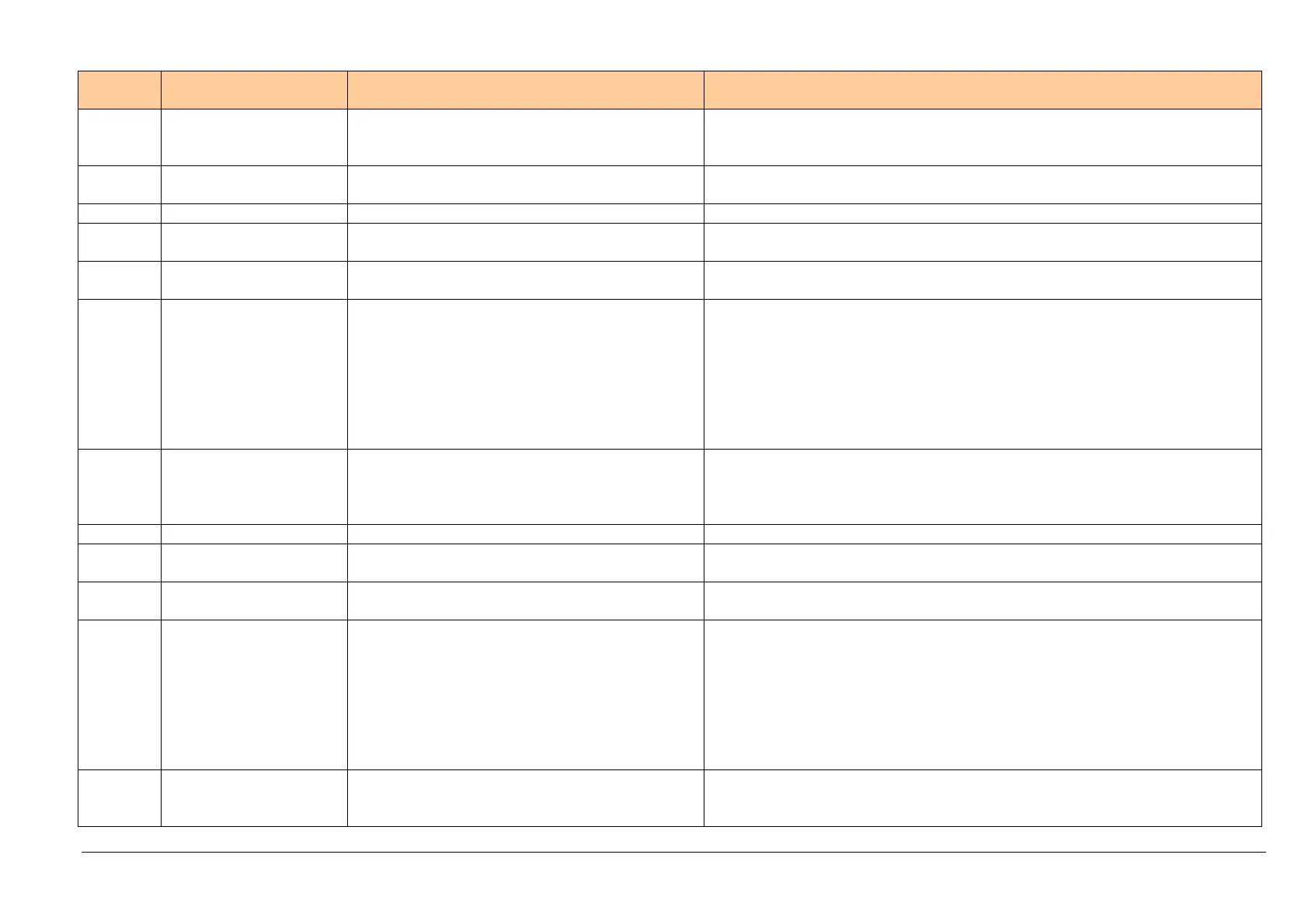

87 # Error air actuator

0 Position error

Target position could not be reached within the required tolerance band.

Check to see if actuator is locked or overloaded.

Bit 0

Valency 1

Line interruption

Line interruption detected at actuator’s terminals.

Check wiring (voltage X53 across pin 5 or 6 and pin 2 >0.5 V).

Bit 3

Valency

8

Curve too steep in terms of ramp rate

Check position differential between the curvepoints and the modulating operating ramp setting

(parameter 544).

1. Modulating operating ramp 32 seconds

The slope of the curve may be a maximum position change of 31° (15° for SQM33.6 and 9° for

SQM33.7) between 2 curve points in modulating mode.

2. Modulating operating ramp 64 seconds

The slope of the curve may be a maximum position change of 62° (30° for SQM33.6 and 18°

for SQM33.7) between 2 curve points in modulating mode.

Bit 4

Valency

16

Sectional deviation in comparison with last referencing

Actuator was overloaded or mechanically twisted.

1. Check the setting of the actuator type (parameter 613.1)

2. Check to see if the actuator is blocked somewhere along its working range.

Loading...

Loading...