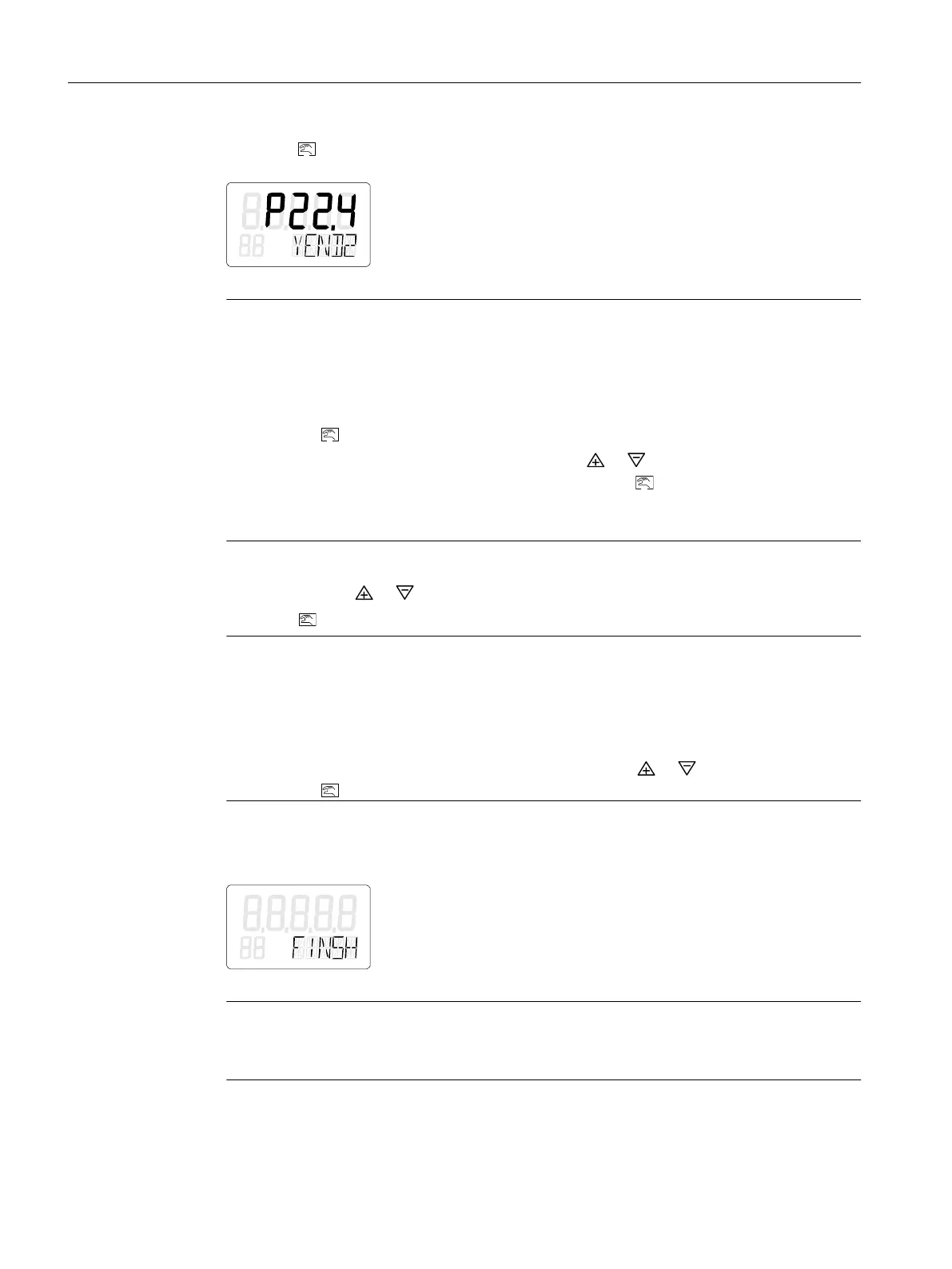

9. Press the button. The current position of the actuator is applied. The display shows the

following:

Note

Fault message "RANGE"

The selected end position is beyond the permissible measuring range if the "RANGE"

message is output on the display. Correct the settings as follows:

1. Move the friction clutch until the display shows "OK".

2. Press the button.

3. Move the actuator to another position using the or button.

4. Abort the manual initialization process by pressing the button.

5. Then return to "P manual mode".

6. Correct the actuator travel and the position detection.

10.Determine the upper endstop of the actuator spindle. Move the actuator to the desired

position using the or button.

11.Press the button. The current position of the actuator is applied.

Note

Fault message "Set Middl"

The lever arm is not in the horizontal position if the "Set Middl" message is output on the

display. To correct the fault, set the reference point of the sine correction. Proceed as

follows:

1. Move the lever arm to the horizontal position using the or button.

2. Press the button.

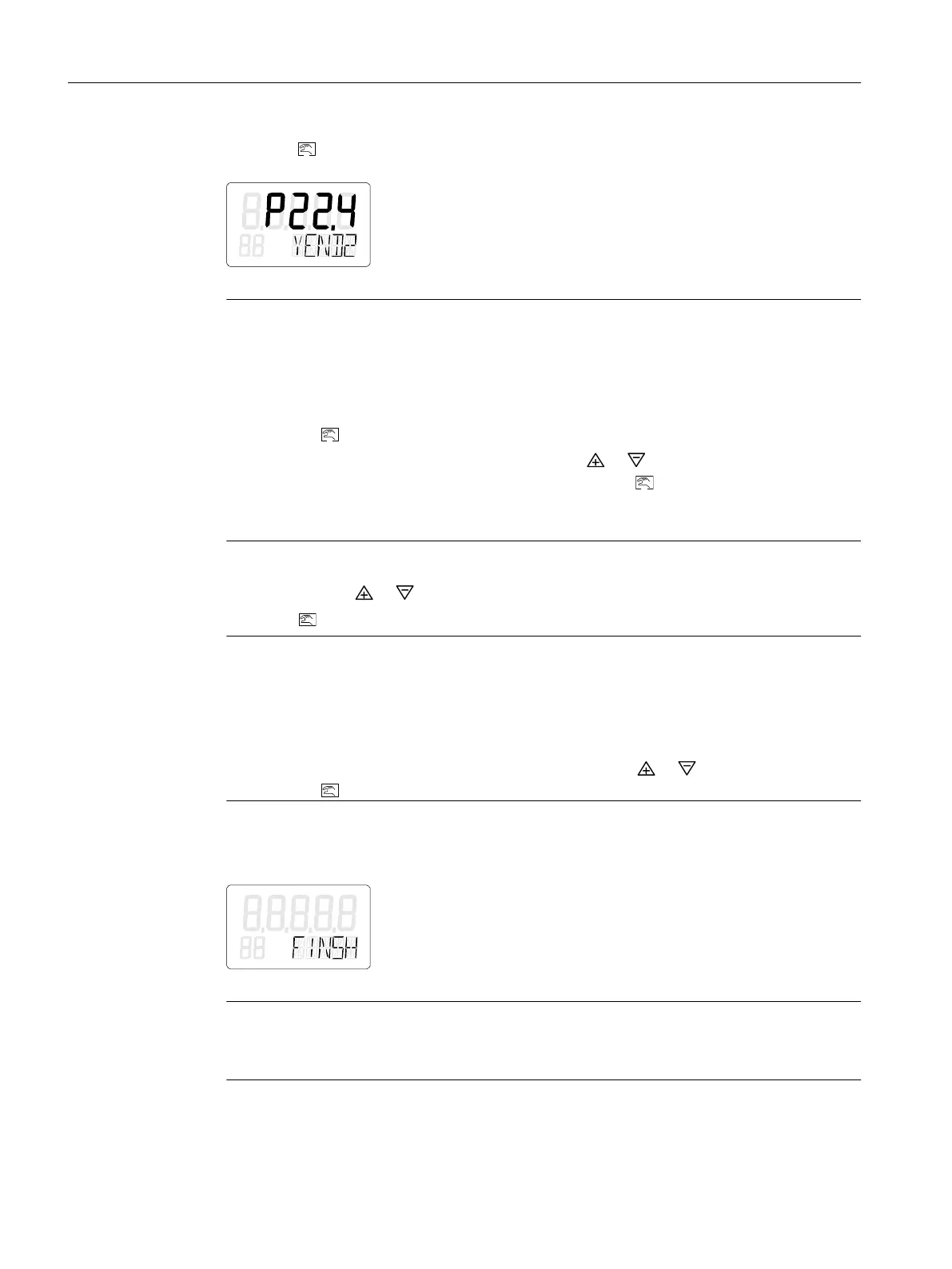

12.The initialization process is automatically resumed. Initialization steps "RUN 1" to "RUN 5"

are output in the bottom line of the display. The following is displayed when the initialization

has been completed successfully:

Note

Total stroke

If the "3.YWAY" parameter has been set, the display shows the total stroke in mm.

Commissioning

7.6 Commissioning linear actuators

SIPART PS2 with PROFIBUS PA

124 Operating Instructions, 05/2019, A5E00127926-AC

Loading...

Loading...