12.4 Fault correction

12.4.1 Fault identification

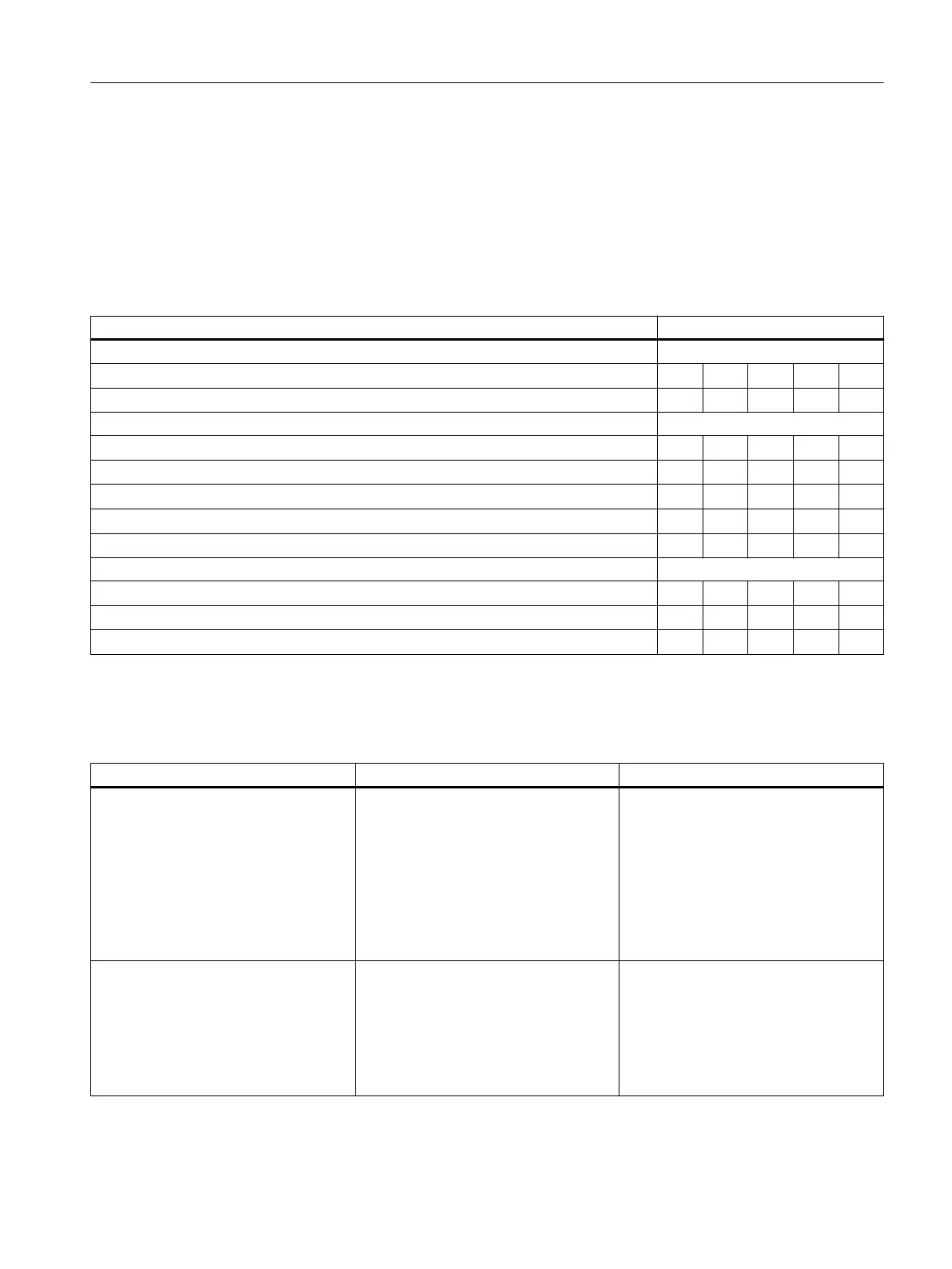

Diagnostics guide

Fault Corrective measures, see table

In which mode does a fault occur?

● Initialization

1

● Manual and automatic modes

2 3 4 5 6

In which environment and under which boundary conditions does a fault occur?

● Wet environment (e.g. strong rain or constant condensation)

2

● Vibrating (oscillating) control valves

2 5

● Impact or shock loads (e.g. vapor shocks or breakaway valves)

5

● Moist (wet) compressed air

2

● Dirty compressed air (contaminated with solid particles)

2 3

When does a fault occur?

● Regularly (reproducible)

1 2 3 4

● Sporadically (not reproducible)

5

● Mostly after a specific operation time

2 3 5

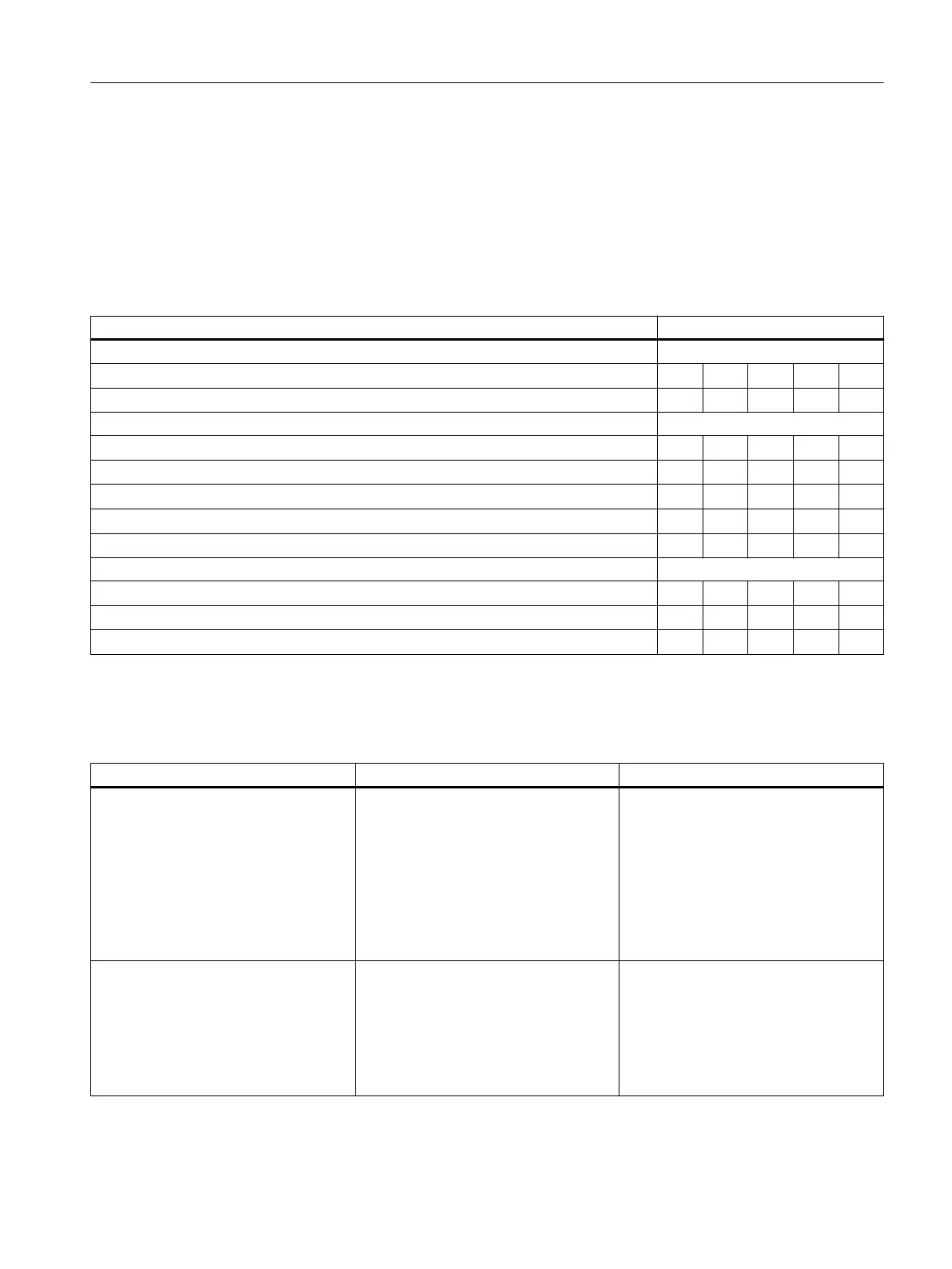

12.4.2 Remedial measures table 1

Fault profile (symptoms) Possible cause(s) Corrective measures

● Positioner remains in "RUN 1". ● Initialization started from the end

position and

● The response time of a maximum of

1 minute was not observed.

● Supply air PZ not connected or

pressure of supply air PZ too low.

● Compressed air line blocked, e.g.

solenoid valve

● A waiting time of up to 1 minute is

essential.

● Do not start initialization from the

end position.

● Ensure supply air PZ.

● Unlock blocked lines.

● Positioner remains in "RUN 2". ● Transmission ratio selector and

parameter 2

● "YAGL" and the real stroke do not

match.

● Incorrectly set stroke on the lever.

● Piezo valve does not activate.

● Check settings: see leaflet: Fig.

"Device view ⑦" as well as

parameters 2 and 3

● Check the stroke setting on the

lever. See Table 2.

Diagnostics and troubleshooting

12.4 Fault correction

SIPART PS2 with PROFIBUS PA

Operating Instructions, 05/2019, A5E00127926-AC 277

Loading...

Loading...