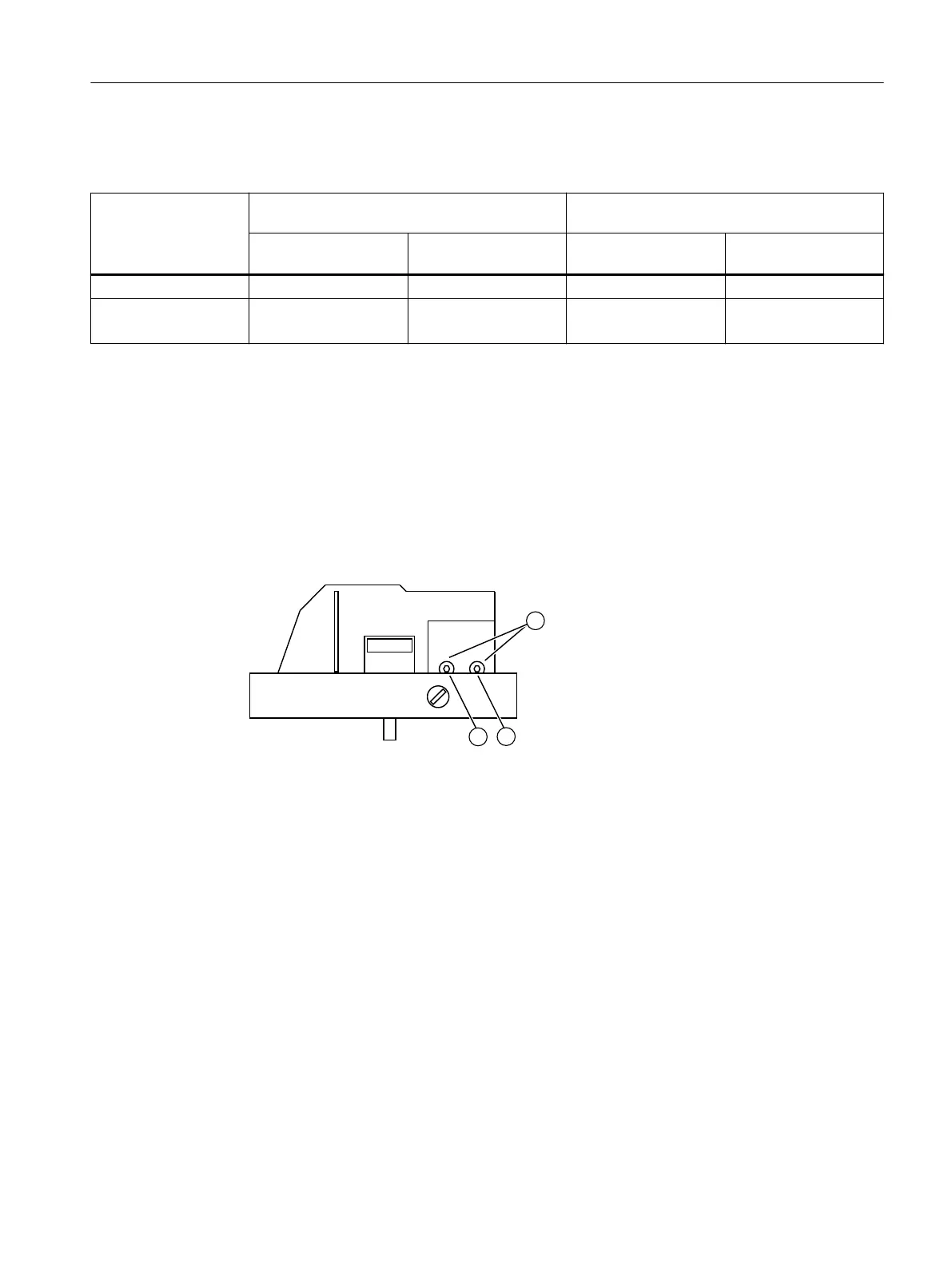

The following table shows the pneumatic connection versions for different actuator types,

regulating action and safety position after an auxiliary power supply failure.

Actuator type Response to failure of auxiliary power: The ac‐

tuator moves into safety position

Fail in place, order suffix F01

Failure of electrical

auxiliary power

Failure of pneumatic

auxiliary power

Failure of electrical

auxiliary power

Failure of pneumatic

auxiliary power

Single-acting Y1 = vented Y1 = vented Y1 = closed Y1 = closed

Double-acting Y1 = pressurized

Y2 = vented

Y1 = closed

Y2 = closed

Y1 = closed

Y2 = closed

Y1 = closed

Y2 = closed

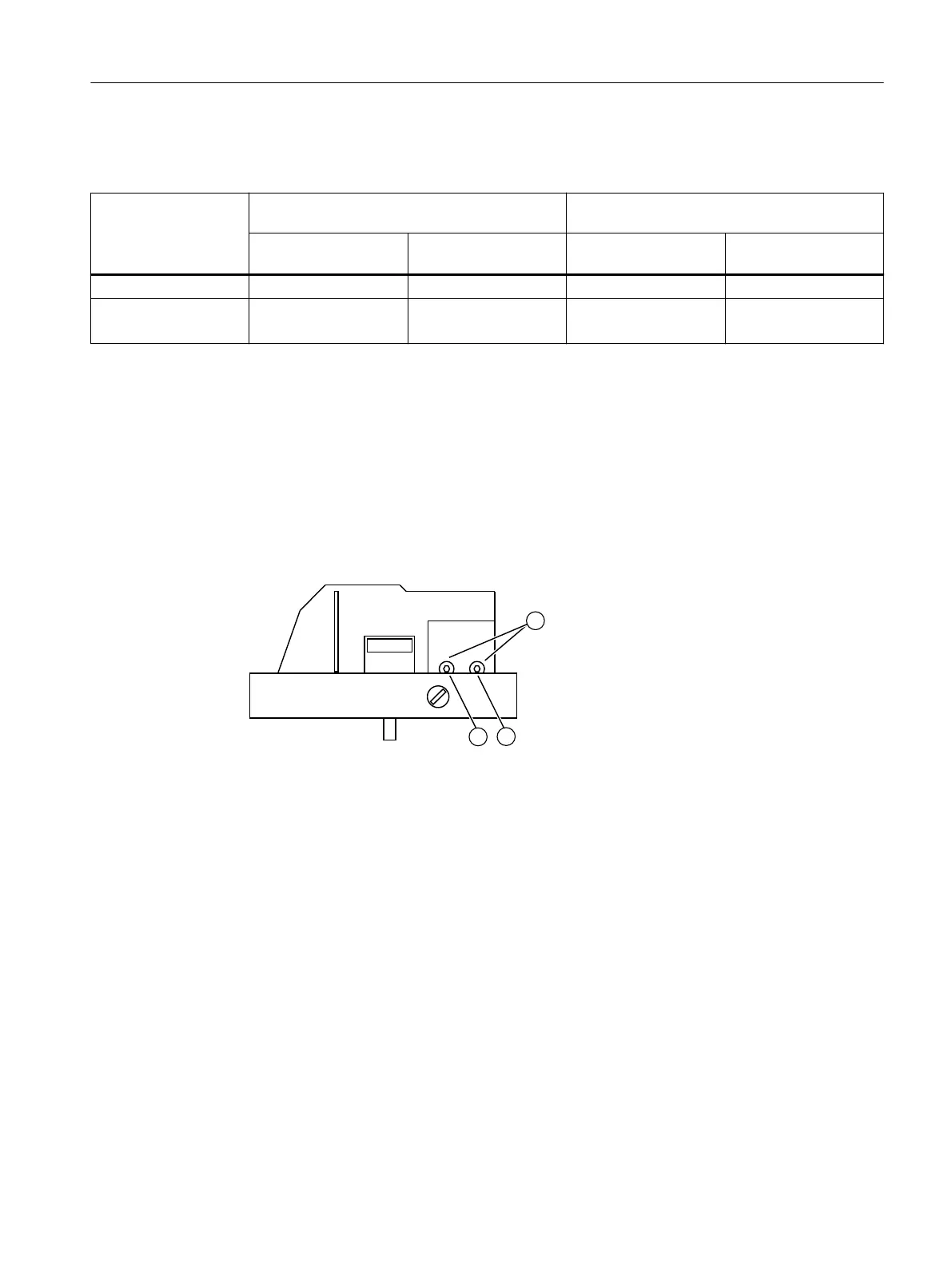

5.4 Restrictors

● Reduce the air output to achieve travel times of T > 1.5 s for small actuators. Use restrictors

Y1 ① and Y2 ② for this purpose.

● When turned clockwise, they reduce the air output and finally shut it off.

● In order to set the restrictors, we recommend closing them and then opening slowly.

● In case of double-acting valves, ensure that both restrictors have approximately the same

setting.

① Restrictor Y1

② Restrictor Y2, only in the version for double-acting actuators *)

③ Hexagon socket-head screw 2.5 mm

Figure 5-13 Restrictors

*) Restrictor Y2 ② is not active for single-acting Fail in Place F01

See also

Sequence of automatic initialization (Page 111)

Connect

5.4 Restrictors

SIPART PS2 with PROFIBUS PA

Operating Instructions, 05/2019, A5E00127926-AC 95

Loading...

Loading...