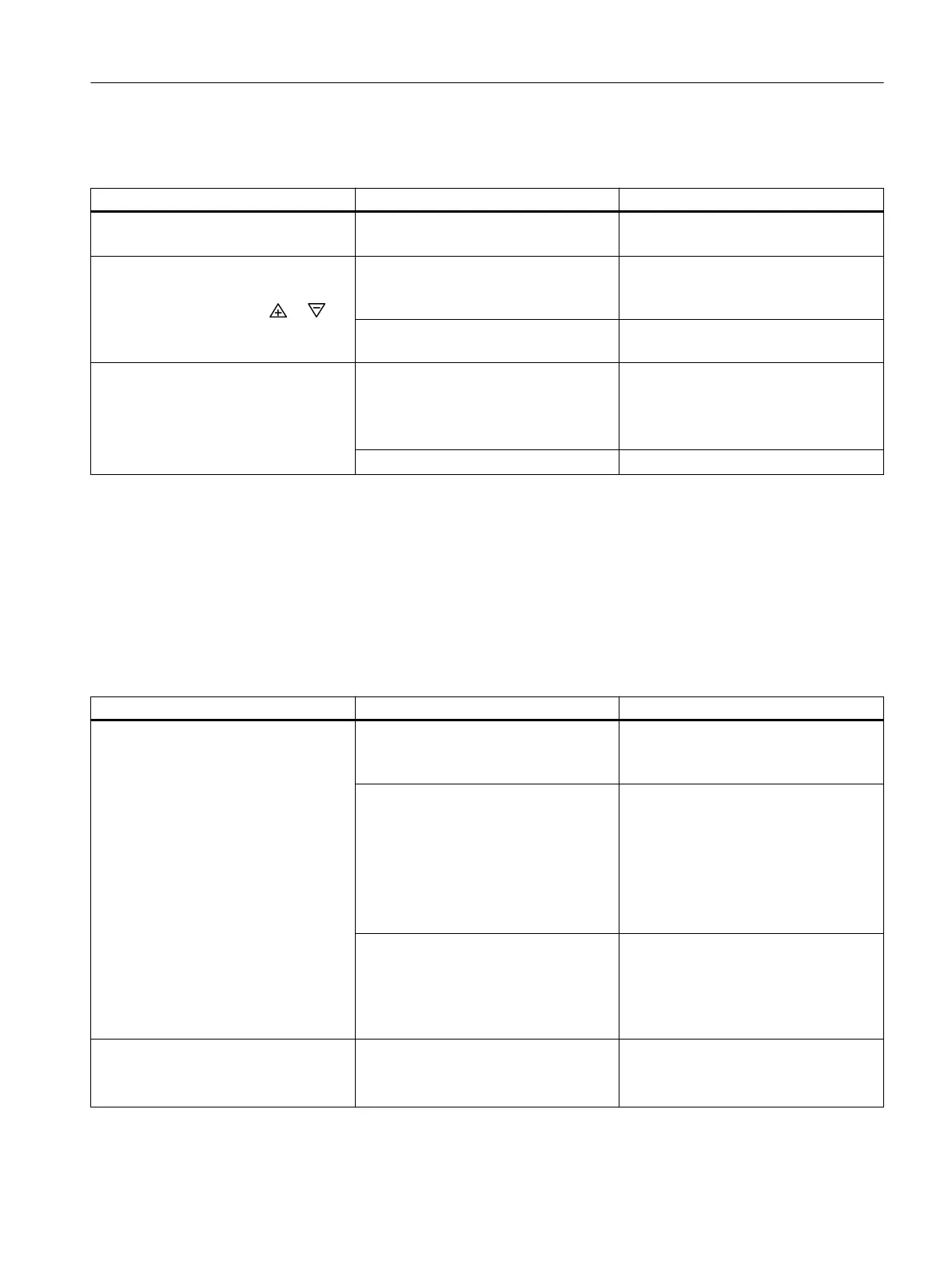

12.4.4 Corrective measures Table 3

Fault profile (symptoms) Possible cause Corrective measures

● Actuator does not move. ● Compressed air < 1.4 bar ● Set pressure of supply air PZ to

> 1.4 bar.

● Piezo valve does not switch

(however, a gentle clicking sound

can be heard when the or

button is pressed in "Manual" mode.)

● Restrictor valve turned off (screw at

the right endstop)

● Open the restrictor screw by turning

it anticlockwise, see leaflet, Fig.

"Device view ⑥".

● Dirt in the pneumatic block ● Repair or a new device; clean and/or

replace the built-in fine screens.

● A piezo valve is switched constantly

in stationary automatic mode

(constant setpoint) and in "Manual"

mode.

● Pneumatic leakage in the positioner

- actuator system; start the leakage

test in "RUN 3" (initialization).

● Rectify leakage in the actuator

and/or feed line.

● In case of an intact actuator and tight

feed line: Repair or new device

● Dirt in the pneumatic block ● See above

Fault table 3

See also

Repair/Upgrading (Page 244)

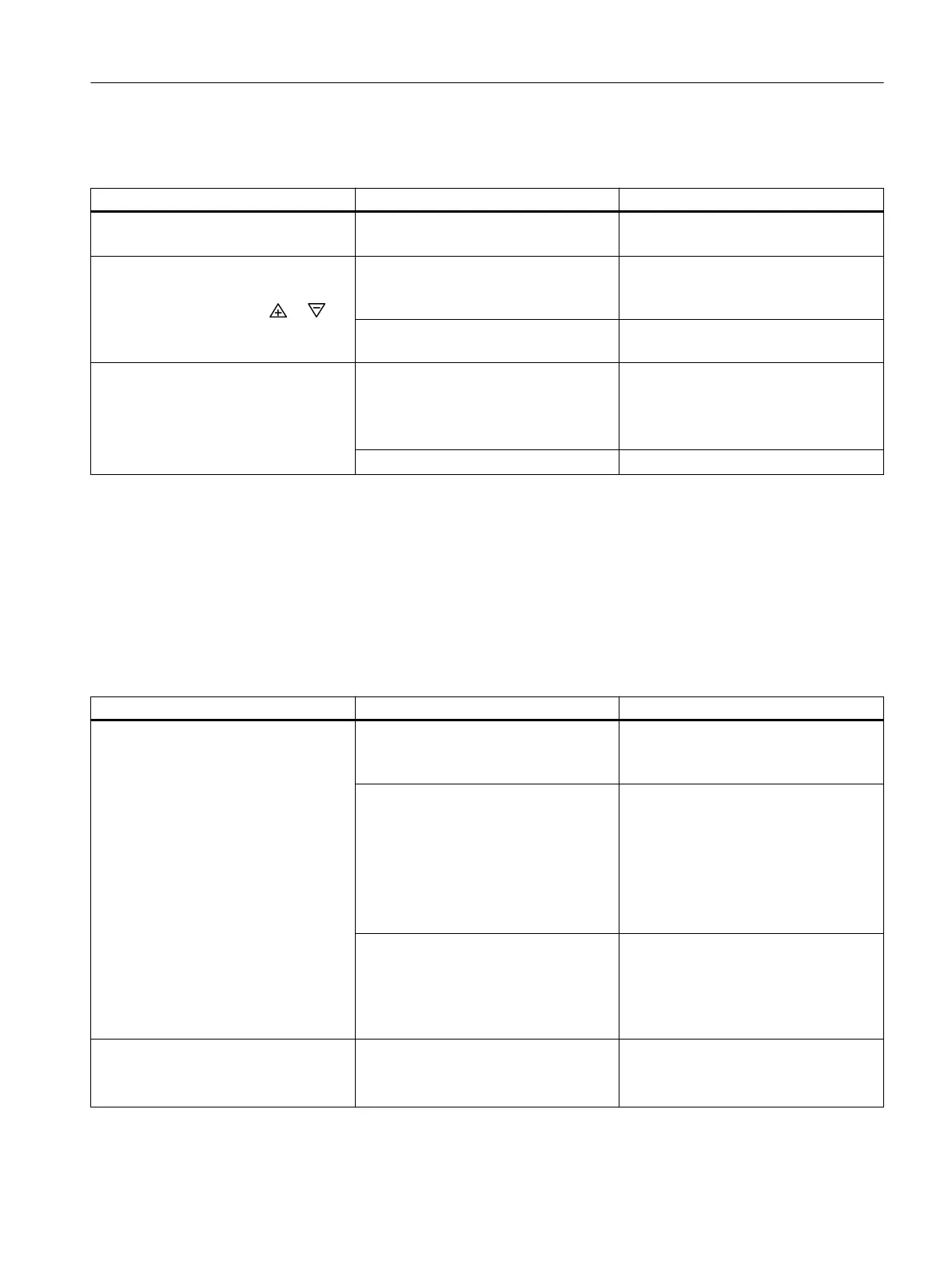

12.4.5 Corrective measures Table 4

Fault profile (symptoms) Possible cause(s) Corrective measures

● In stationary automatic mode

(constant setpoint) and in "Manual"

mode, both piezo valves continually

switch alternately, and the actuator

oscillates around an average value.

● Stiction of the packing gland from

the control valve or actuator too large

● Reduce stiction or increase

deadband of positioner (parameter

"dEbA") until the oscillation stops.

● Looseness (play) in the positioner/

actuator/control valve system

● Part-turn actuator: Check for firm

seating of set screw on coupling

wheel.

● Linear actuator: Check for firm

seating of lever on positioner shaft.

● Correct any other play between the

actuator and the control valve.

● Actuator too fast ● Increase travel times using throttle

screws.

● If a quick travel time is needed,

increase the deadband (parameter

"dEbA") until the oscillation stops.

● Positioner doesn't move control

valve to the stop (at 20 mA).

● Supply pressure too low. Load on

the feeding controller or system

output is too low.

● Increase supply pressure, insert

ballast converter

● Select 3/4-wire mode

Error table 4

Diagnostics and troubleshooting

12.4 Fault correction

SIPART PS2 with PROFIBUS PA

Operating Instructions, 05/2019, A5E00127926-AC 279

Loading...

Loading...