The contents of the "Device status" parameter from the physical block are reported along with

the information whether a status change (event received/event sent) has occurred.

Diagnostics as per PROFIBUS DP (DDLM_Slave_Diag)

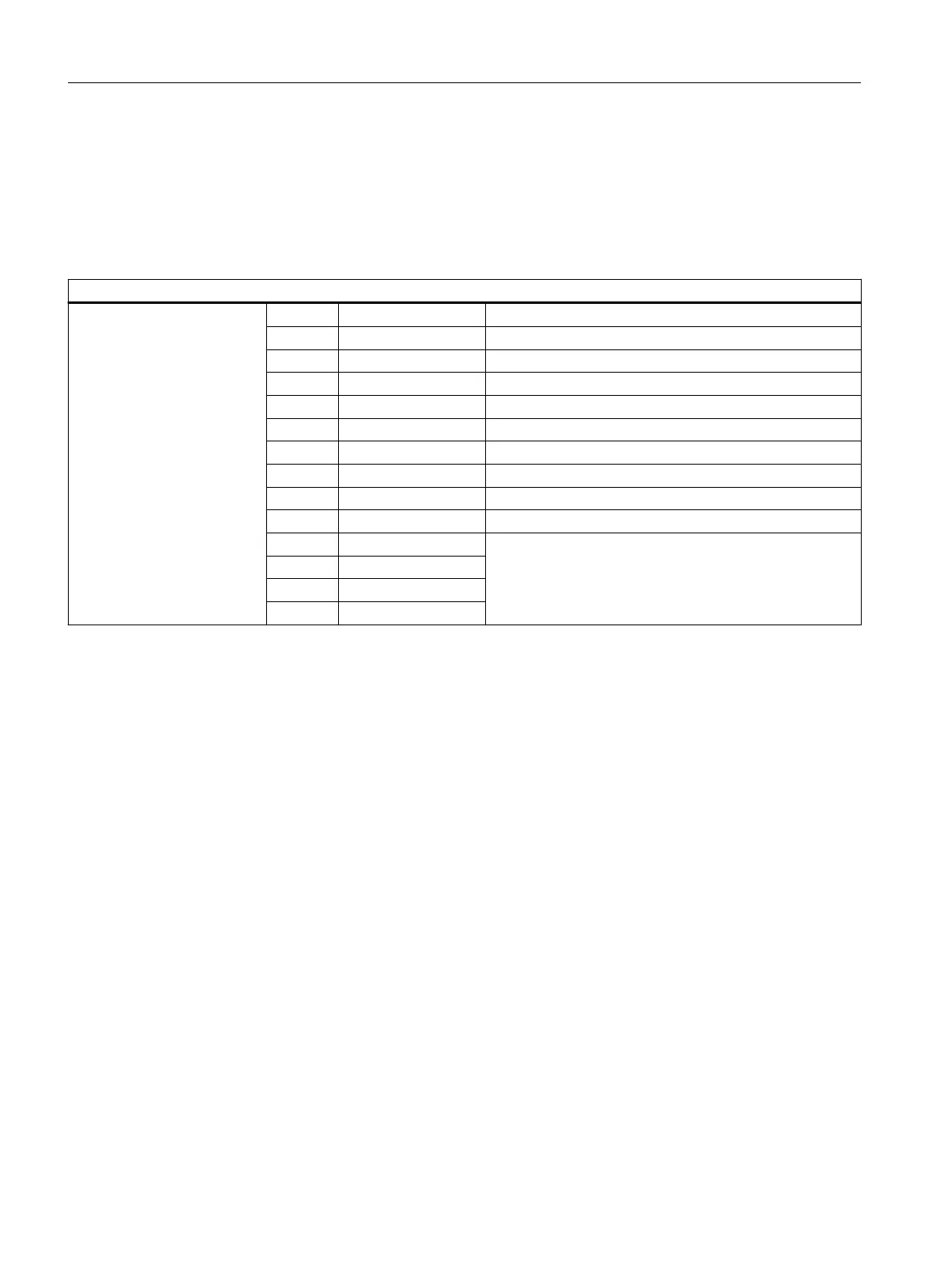

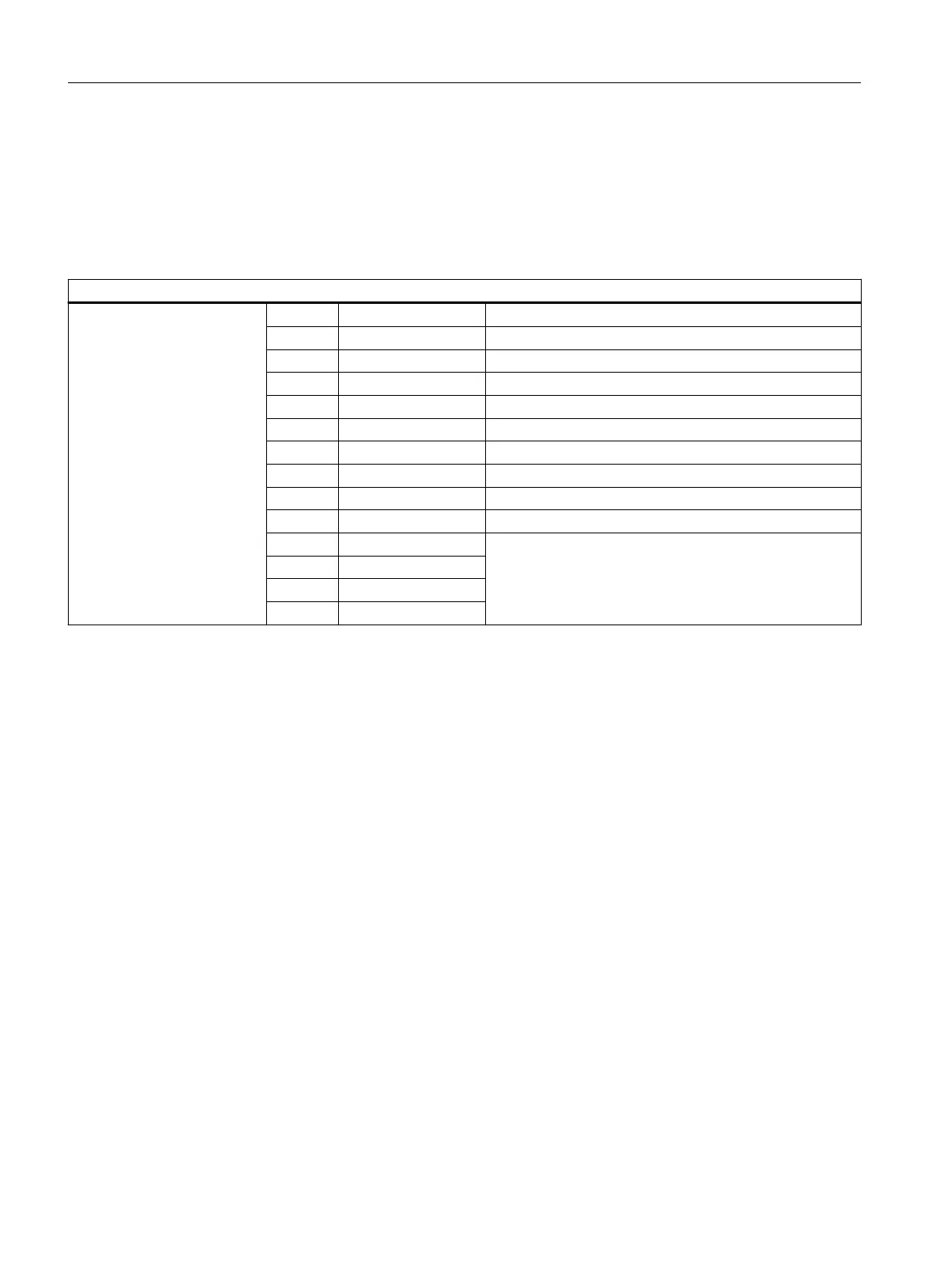

The positioner delivers the diagnostics data in the following format:

Input (master view)

Starting address 0 Station_status_1

1 Station_status_2

2 Station_status_3 Standard DP - diagnostics

3 Diag_Master_Add

4 Ident_Number

5 Ident_Number

6 Header

7 Status_Type Status coding as per DP/V1

8 Slot_Number

9 Specifier

10 Diagnostics (0) Diagnostics object of the physical block

11 Diagnostics (1)

12 Diagnostics (2)

13 Diagnostics (3)

Specifier

The following specifiers are available:

1: Incoming event

2: Outgoing event

9.3.3 Adjustable status (condensed status)

Diagnostics messages are generated in the DIAGNOSTICS physical block parameter

depending on the diagnostics events in the device. At the same time, the statuses of three

PowerTags (FEEDBACK_VALUE, READBACK and POS_D) that are sent to the master by the

SIPART PS2 PA positioner are affected.

In the device, there is now an option to use diagnostics messages and predefined status

messages that are permanently associated with the triggering diagnostics events. The

condensed status must be deactivated for this purpose.

If the condensed status is activated, the diagnostics messages in a specific frame can be

allocated to a smaller number of collective diagnostics messages and selectable status

messages. This "routing" of diagnostics events is shown in the following picture.

Functions/operations using PROFIBUS PA

9.3 Cyclic data transfer

SIPART PS2 with PROFIBUS PA

218 Operating Instructions, 05/2019, A5E00127926-AC

Loading...

Loading...