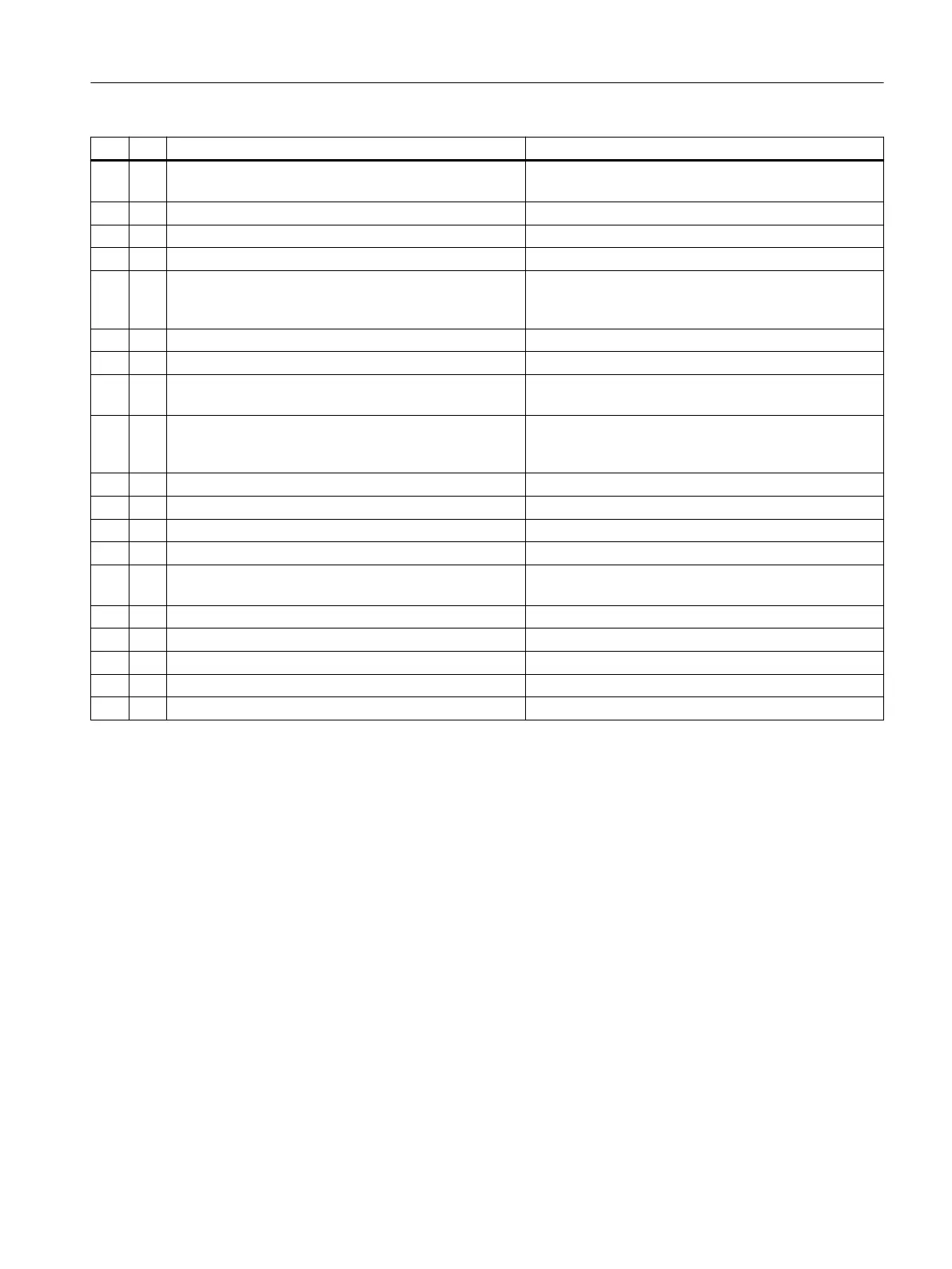

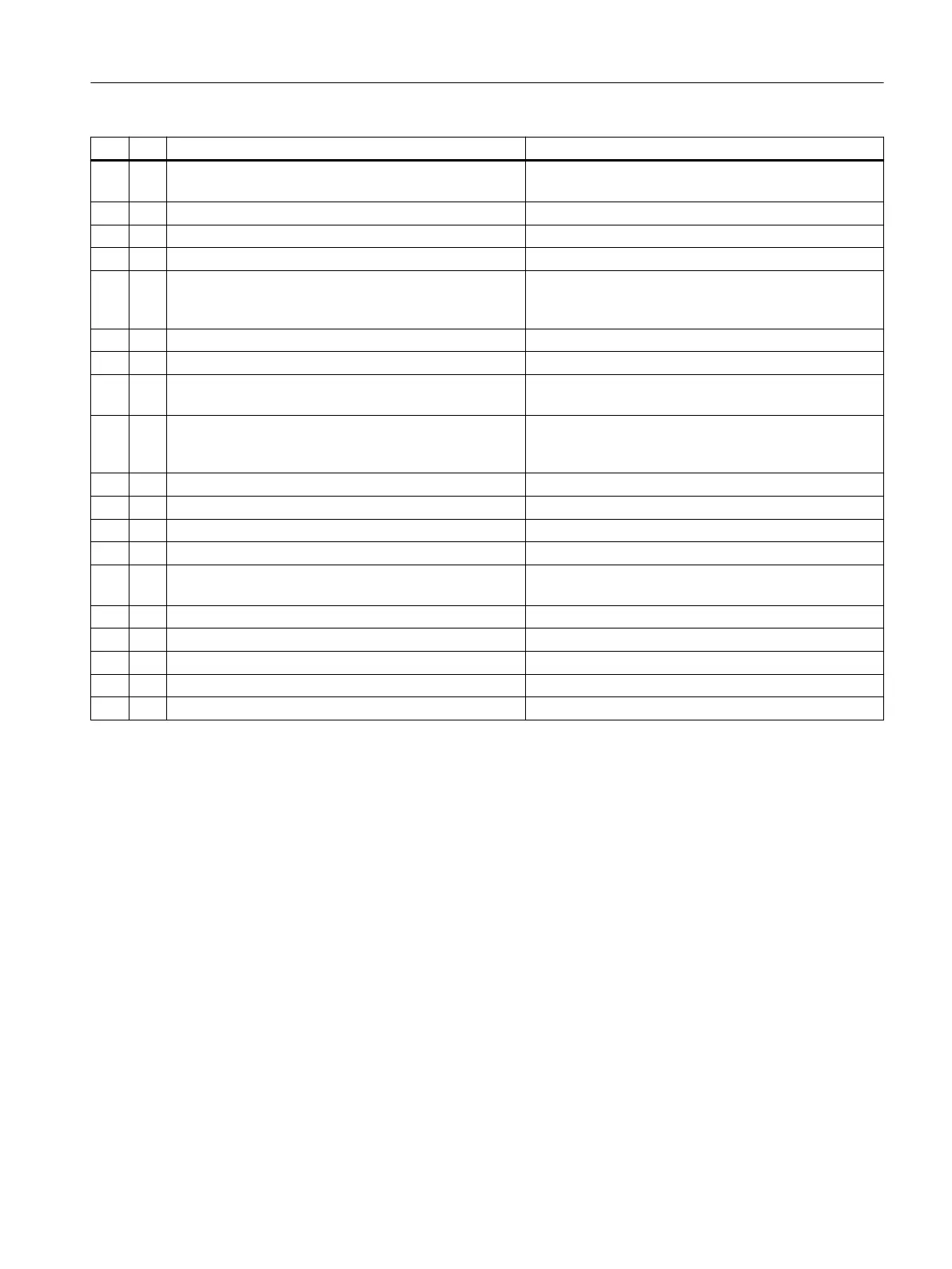

Bit Meaning of "1" Remarks

3 Emergency operation active The device is in the manual mode. Representation on

the display: MAN or P

4 Deviation of the movement direction Not required for the positioner.

5 End stop reached (valve completely open) Not required for the positioner.

6 End stop reached (valve completely closed) Not required for the positioner.

7 Run time overshoot The device could not be adjusted. Monitoring time and

threshold in the "44.TIM" and "45.LIM" parameters ex‐

ceeded, e.g. due to the lack of compressed air

1 0 The valve is opened. The "Ventilate actuator" command issued

1 The valve is closed. The "Depressurize actuator" command issued

2 Parameters were changed. Set temporarily after switching back from the "Configu‐

ration" mode if one or more parameters were changed.

3 Simulation mode The simulation mode was released. Master class 2 can

overwrite the current actual value, e.g., to test the re‐

sponse of limits in the control system.

4 Not occupied in profile 3. -

5 Fault in the closed-loop control. Not required for the positioner.

6 Closed-loop control inactive Not required for the positioner.

7 Self-monitoring active Not required for the positioner.

2 0 Path integral exceeded Set if the set limit for the path integral has been excee‐

ded.

1 Additional input active Binary 1 was activated.

2 Additional input active Binary 2 was activated.

3 Fault message output active Fault message output was activated.

4 Alarm output A1 active Alarm output 1 was activated.

5 Alarm output A2 active Alarm output 2 was activated.

Remote cascade input

The remote cascade input is used as a setpoint in the remote cascade mode (actual mode =

remote cascade). The remote cascade input comprises the floating point value (4 bytes) and

the status (1 byte).

Remote cascade output

This output delivers the current setpoint in the AUTO and Remote cascade modes. The status

is specially used for the transfer from AUTO to Remote cascade.

In combination with the input variable parameter (primary value scale), not only you can define

the setpoints as a percentage of the valve position, but also in terms of physical variables such

as cubic meter per day or liter per minute. Even the actual values are adjusted as per this scale.

Functions/operations using PROFIBUS PA

9.3 Cyclic data transfer

SIPART PS2 with PROFIBUS PA

Operating Instructions, 05/2019, A5E00127926-AC 213

Loading...

Loading...