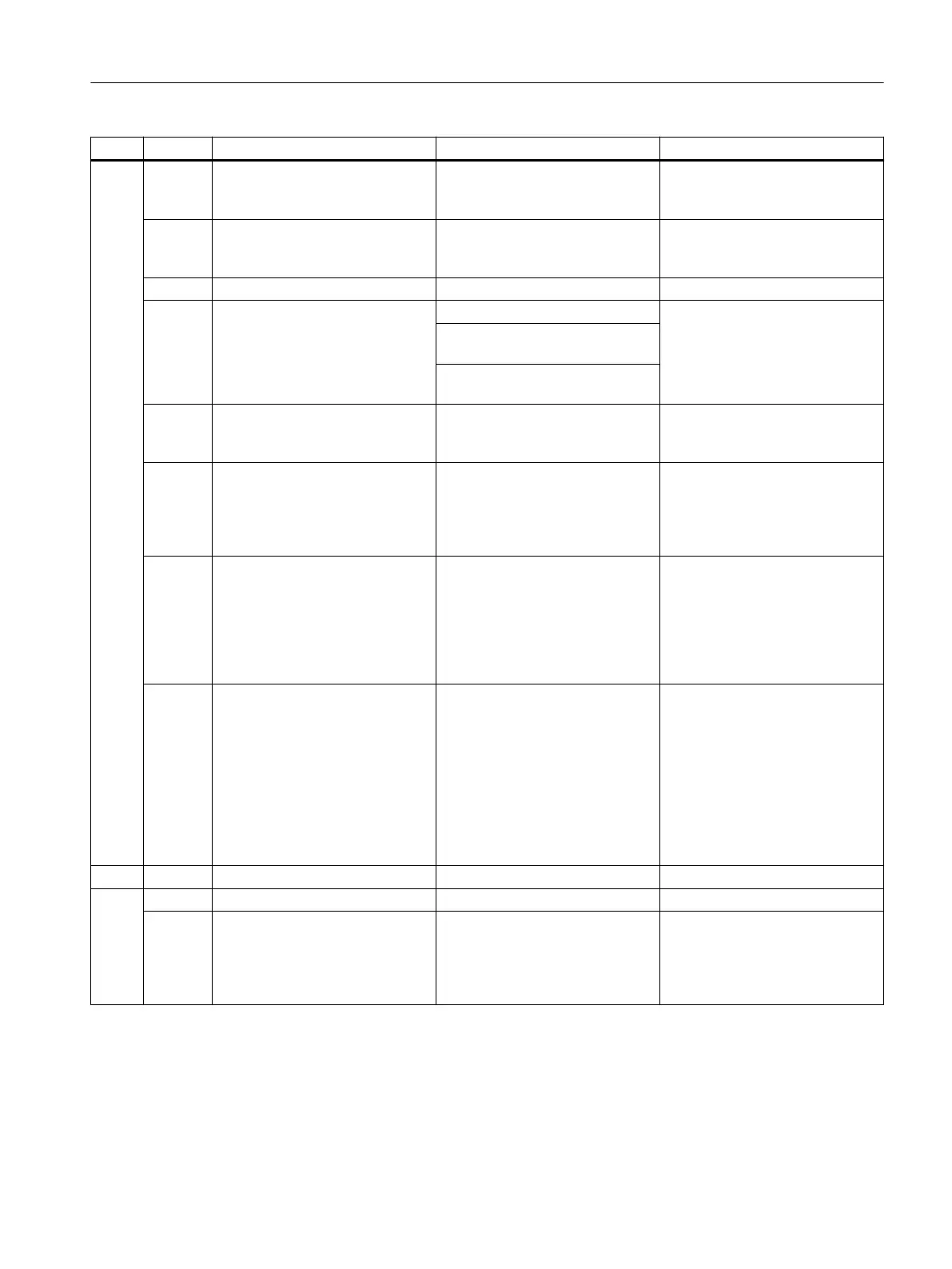

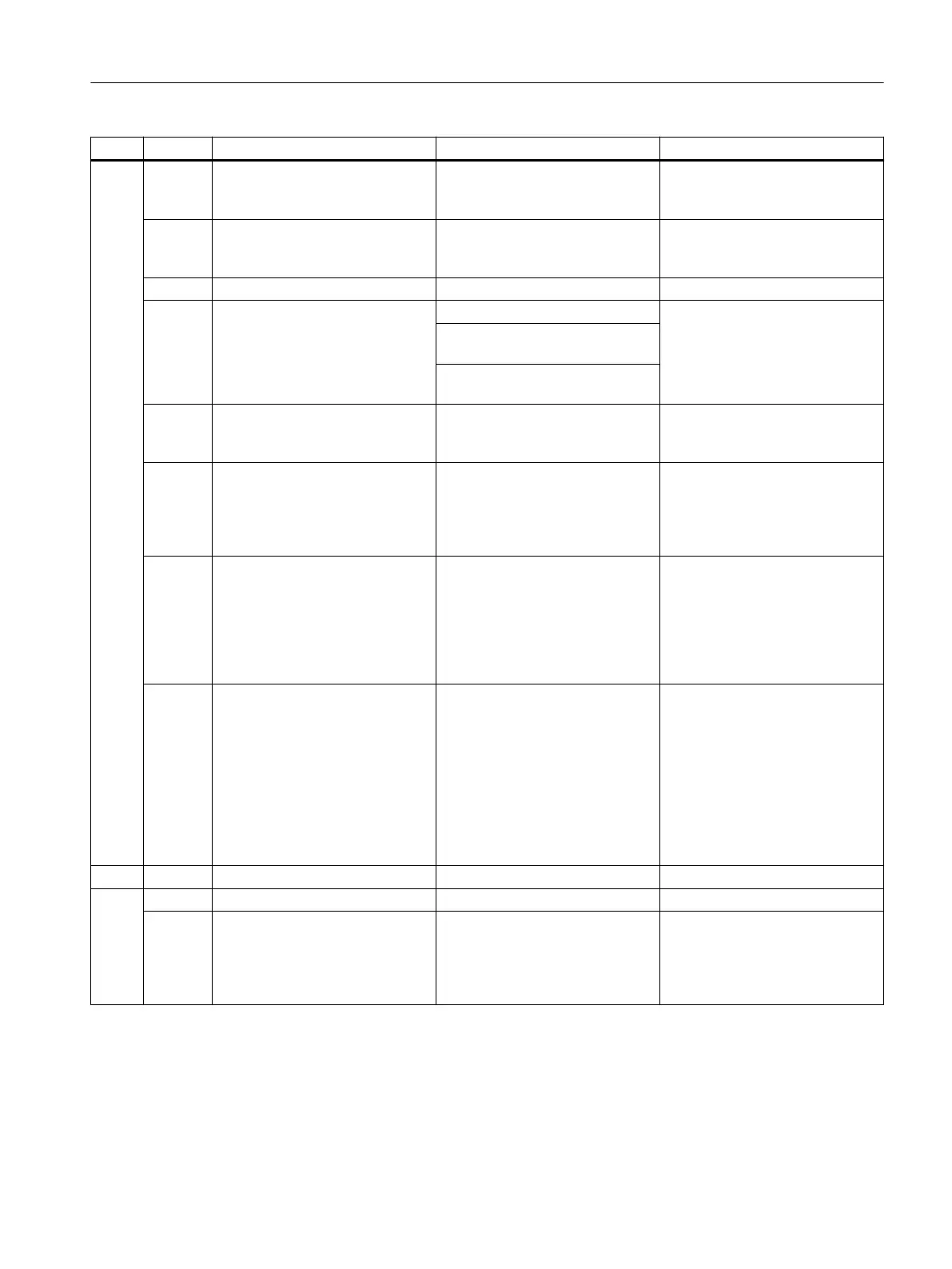

Byte Bit Name and meaning Cause Measure

1 0 DIA_ZERO_ERR

Lower end stop beyond the toler‐

ance

The lower end stop is beyond the

set tolerance.

Check the valve. Flow restrictors

and/or the seat ring are probably

worn out.

1 DIA_SUPPLY

Error in the compressed air supply

A run time overshoot was detec‐

ted. In all probability, the energy

(compressed air) is not available.

Establish the compressed air sup‐

ply and check the feed lines.

2 Not used - -

3 DIA_WARMSTART

Warm restart executed (goes to

"0" after 10 s)

Power was fed to the device. Check the cabling and the supply

unit.

SIMATIC PDM was used to trig‐

ger a warm restart.

The internal watchdog has re‐

sponded.

4 DIA_COLDSTART

Restart executed

(goes to "0" after 10 s)

The device was reset to factory

settings.

-

5 DIA_MAINTENANCE

Maintenance required

To determine the cause, check in

DIAGNOSTICS_EXTENSION

and DIAGNOSTICS_EXTEN‐

SION_2 which diagnostics event

has triggered the message.

Depends on the triggering diag‐

nostics event.

6 DIA_CHARACT

Characteristic curve invalid

The parameterized characteristic

curve does not have the required

monotony, number of support

points, or the x values are not ar‐

ranged in 5% distances. The orig‐

inal characteristic curve is used

further.

Modify the configuration data

(change the GSD) such that it is

consistent with the identification

number set in the device.

7 IDENT_NUMBER_VIOLATION

Identification number changed

You have changed the PROFI‐

BUS identification number param‐

eter during the active cyclic oper‐

ation. The device reports the iden‐

tification number violation and dis‐

plays a failure warning. In case of

a warm restart, the device no lon‐

ger participates in the cyclic trans‐

fer of useful data without chang‐

ing the system configuration.

Modify the configuration data

(change the GSD) such that it is

consistent with the identification

number set in the device.

2 0 ... 7 Reserved - -

3 0 ... 6 Reserved - -

7 EXTENSION_AVAILABLE

Extension available

Further information about the trig‐

gering diagnostics event is avail‐

able in DIAGNOSTICS_EXTEN‐

SION and DIAGNOSTICS_EX‐

TENSION_2.

-

Functions/operations using PROFIBUS PA

9.3 Cyclic data transfer

SIPART PS2 with PROFIBUS PA

Operating Instructions, 05/2019, A5E00127926-AC 223

Loading...

Loading...