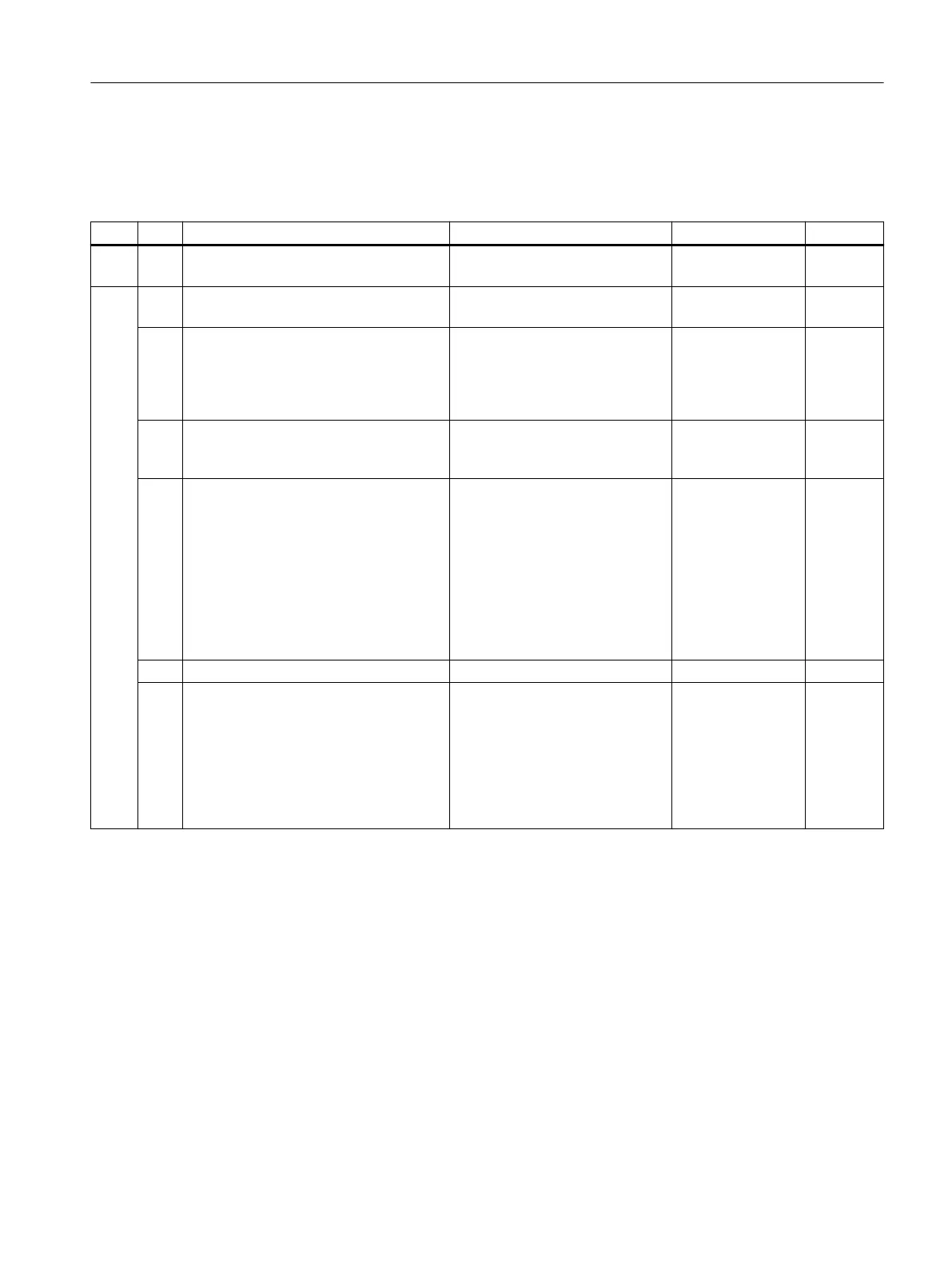

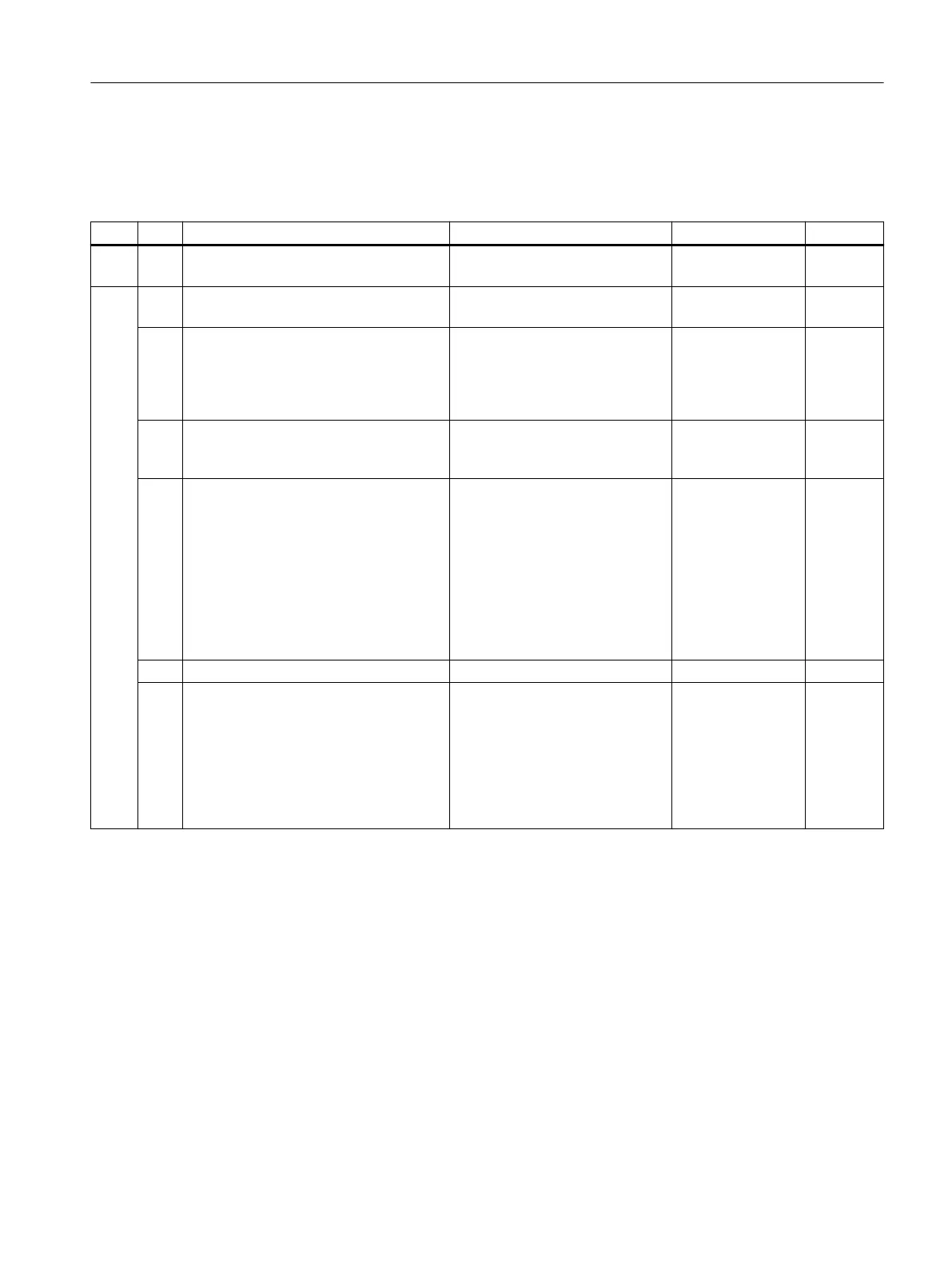

Collective diagnostics messages

Collective diagnostics messages in the case of the activated condensed status are shown in

the following table:

Byte Bit Name and meaning Cause Measures Group

0 0

... 7

Reserved - - -

1 0

... 2

Reserved - - -

3 DIA_WARMSTART

Warm restart executed (goes to "0" after

10 s)

To determine the cause, check in

DIAGNOSIS_EXTENSION and

DIAGNOSIS_EXTENSION_2

which diagnosis event has trig‐

gered the message.

Check the wiring

and the supply volt‐

age.

-

4 DIA_COLDSTART

Restart executed

(goes to "0" after 10 s)

- - -

5 DIA_MAINTENANCE

Maintenance required

You have changed the PROFI‐

BUS identification number pa‐

rameter during the active cyclic

operation. The device reports the

identification number violation

and displays a failure warning. In

case of a restart, the device will

no longer participate in cyclic

user data exchange unless the

system configuration is changed.

Depends on the

triggering diagnos‐

tics event.

M1, M12,

M

6 Reserved - - -

7 IDENT_NUMBER_VIOLATION

Identification number changed

To determine the cause, check in

DIAGNOSIS_EXTENSION and

DIAGNOSIS_EXTENSION_2

which diagnosis event has trig‐

gered the message.

Modify the configu‐

ration data

(change the GSD)

such that it is con‐

sistent with the

identification num‐

ber set in the de‐

vice.

-

Functions/operations using PROFIBUS PA

9.3 Cyclic data transfer

SIPART PS2 with PROFIBUS PA

Operating Instructions, 05/2019, A5E00127926-AC 225

Loading...

Loading...