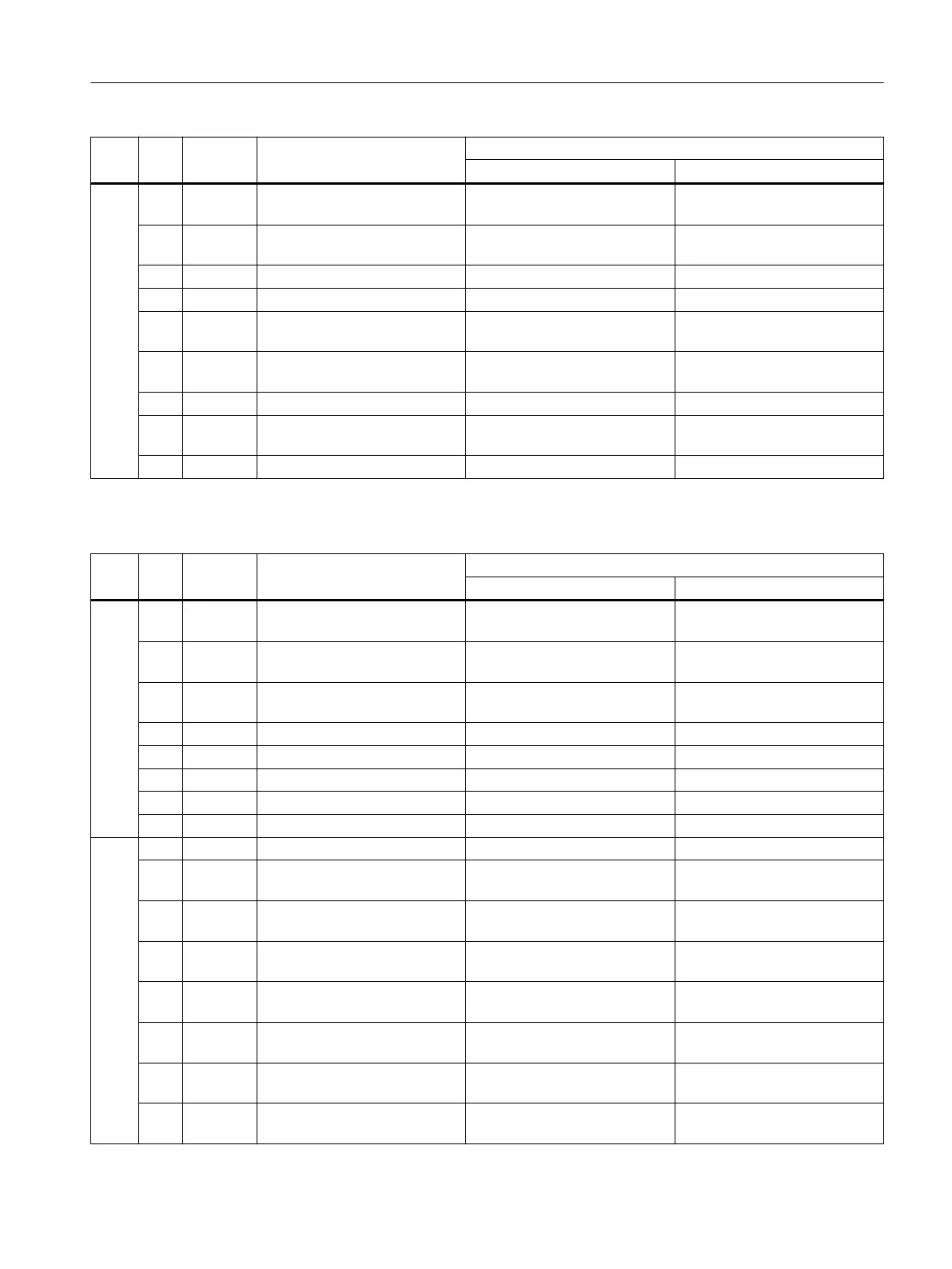

Byte Bit No. Diagnostics events Hard-coded effect of a diagnostics event

Quality status code DIAGNOSTICS bit

3 0 25 The device is not yet ready for

operation (not initialized)

Bad, configuration error DIA_NOT_INIT

1 26 The device is not yet ready for

operation (initialization error)

Bad, configuration error DIA_INIT_ERR

3 27 Reserved - -

3 28 Reserved - -

4 29 Device in the Manual mode (FB

in the Manual mode)

Depends on the set status None

5 30 Device in the Simulation mode

(FEEDBACK is simulated)

Depends on the simulated sta‐

tus

None

6 31 Device in the TRACE mode - None

7 32 Diagnostics simulation (diag‐

nostics events are simulated)

Depends on the simulated di‐

agnostics event

Depends on the simulated di‐

agnostics event

33 ... 48 Reserved - -

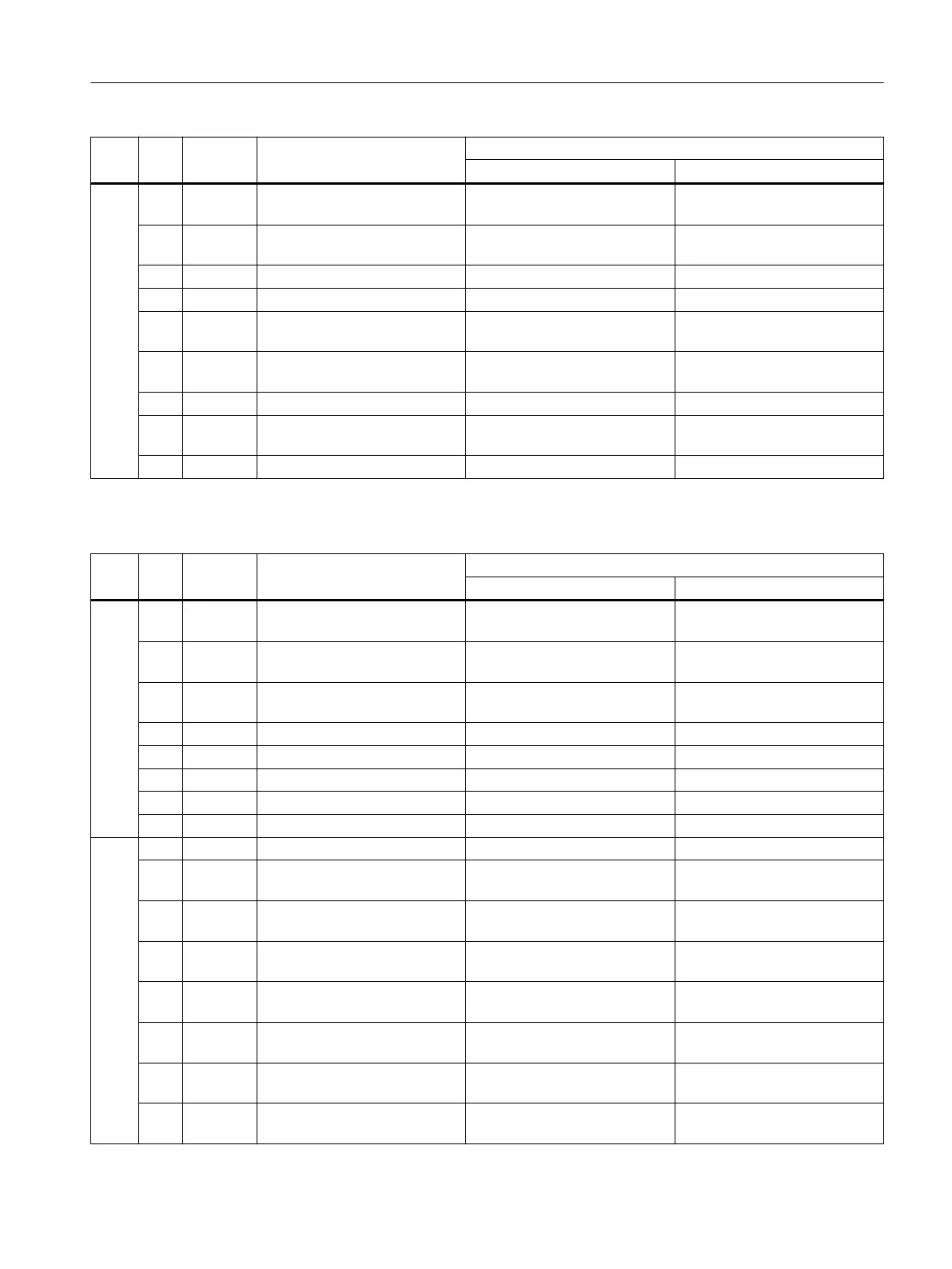

DIAGNOSTICS_EXTENSION_2 physical block parameter

Byte Bit No. Diagnostics events Hard-coded effect of a diagnostics event

Quality status code DIAGNOSTICS bit

0 0 49 General control valve fault (lim‐

it 1)

Good, maintenance required DIA_MAINTENANCE

1 50 General control valve fault (lim‐

it 2)

Good, maintenance required DIA_MAINTENANCE

2 51 General control valve fault (lim‐

it 3)

Good, maintenance required DIA_MAINTENANCE

3 52 Pneumatic leakage (limit 1) Good, maintenance required DIA_MAINTENANCE

4 53 Pneumatic leakage (limit 2) Good, maintenance required DIA_MAINTENANCE

5 54 Pneumatic leakage (limit 3) Good, maintenance required DIA_MAINTENANCE

6 55 Static friction (limit 1) Good, maintenance required DIA_MAINTENANCE

7 56 Static friction (limit 2) Good, maintenance required DIA_MAINTENANCE

1 0 57 Static friction (limit 3) Good, maintenance required DIA_MAINTENANCE

1 58 Lower end stop monitoring (lim‐

it 1)

Good, maintenance required DIA_ZERO_ERR

2 59 Lower end stop monitoring (lim‐

it 2)

Good, maintenance required DIA_ZERO_ERR

3 60 Lower end stop monitoring (lim‐

it 3)

Good, maintenance required DIA_ZERO_ERR

4 61 Upper end stop monitoring (lim‐

it 1)

Good, maintenance required DIA_ZERO_ERR

5 62 Upper end stop monitoring (lim‐

it 2)

Good, maintenance required DIA_MAINTENANCE

6 63 Upper end stop monitoring (lim‐

it 3)

Good, maintenance required DIA_MAINTENANCE

7 64 Limit 1 for path integral (100%

strokes) exceeded

Good, maintenance required DIA_MAINTENANCE

Functions/operations using PROFIBUS PA

9.3 Cyclic data transfer

SIPART PS2 with PROFIBUS PA

Operating Instructions, 05/2019, A5E00127926-AC 229

Loading...

Loading...