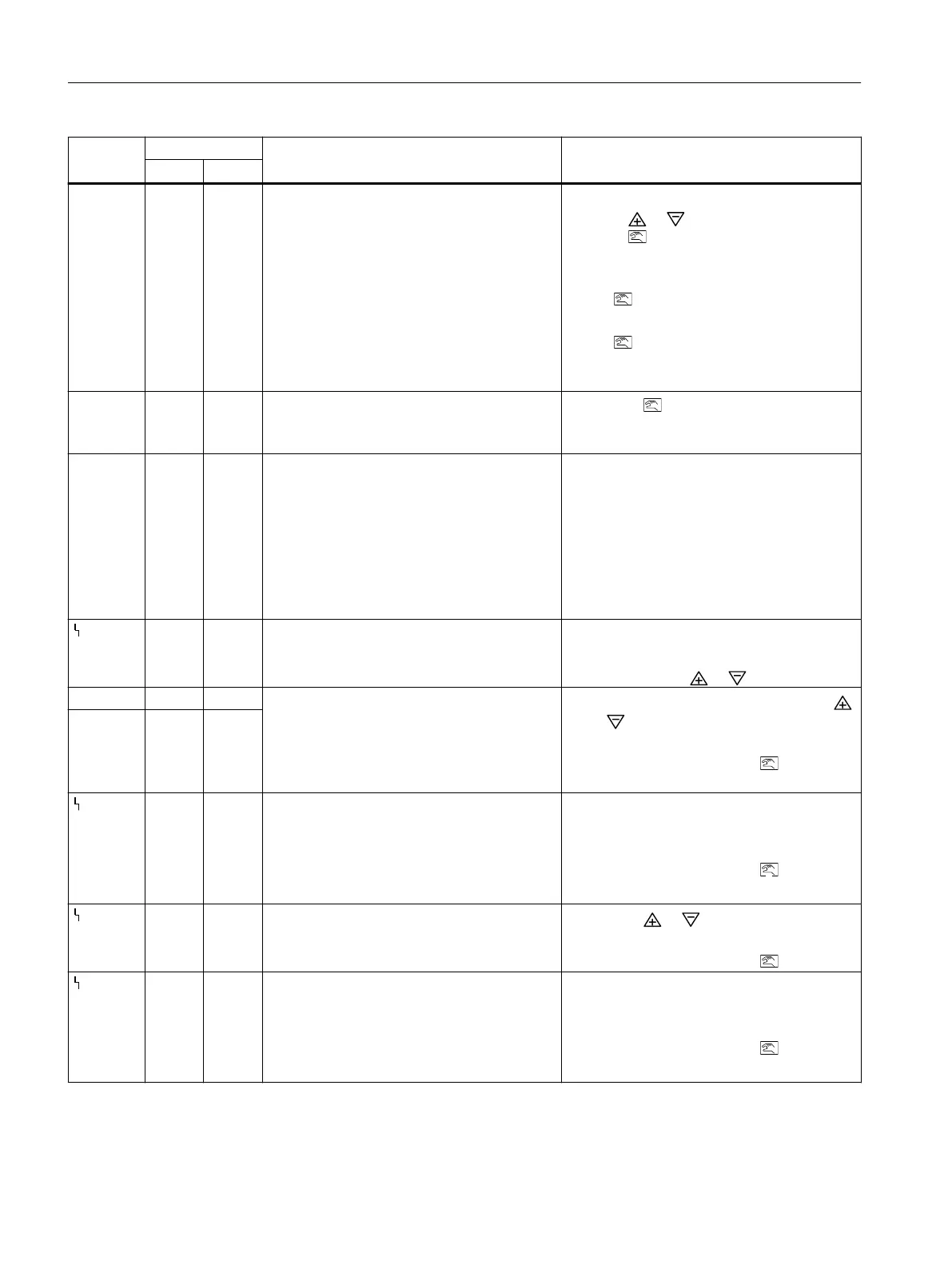

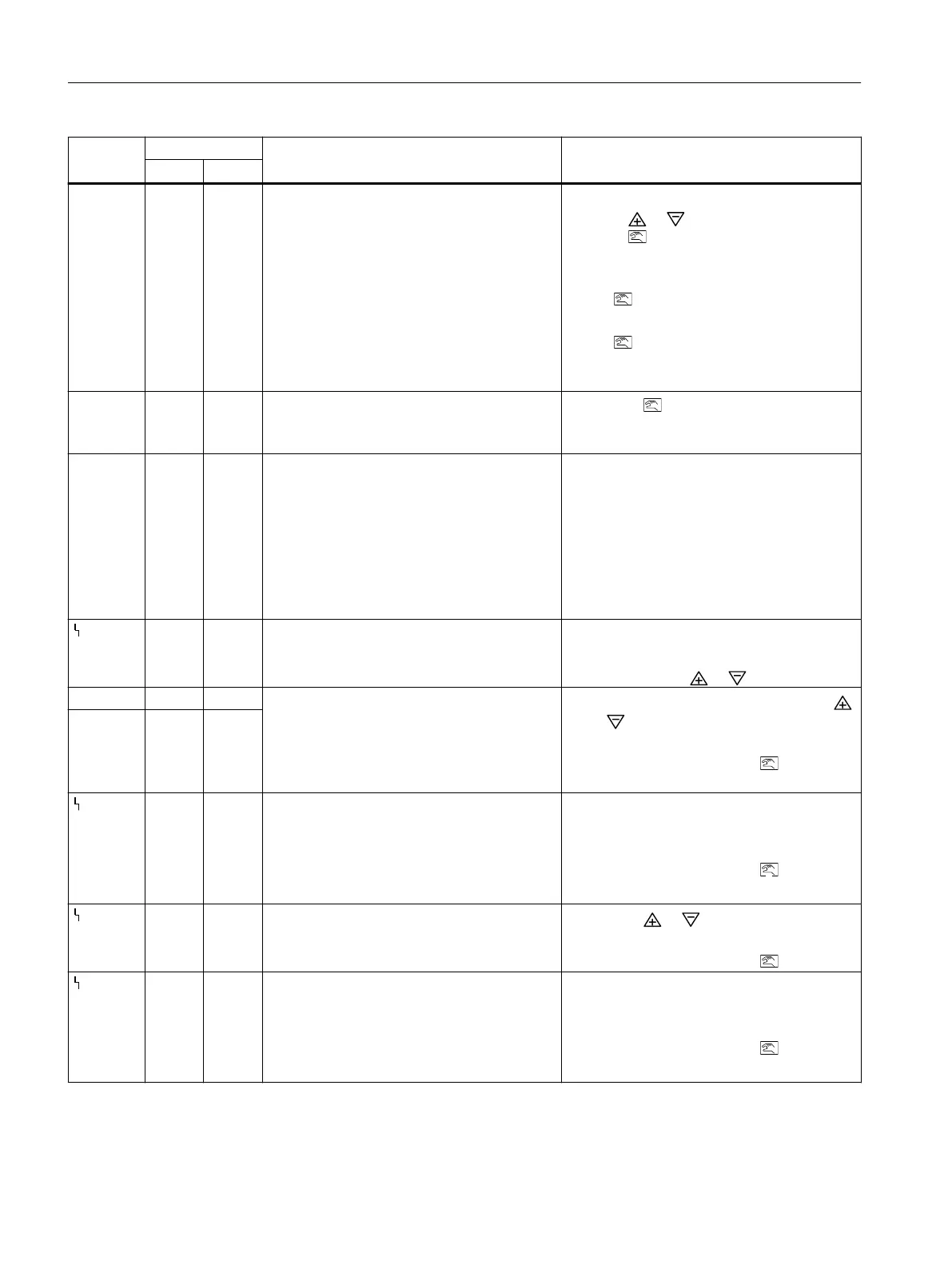

Message Line Meaning/cause Measure

Up Down

RANGE X The position of the stop or the measuring

span is beyond the permissible measuring

range only in case of a manual initialization

● Approach a different position of the stop

using or button and acknowledge

using button.

● Move the friction clutch until "ok" is

displayed, and then acknowledge with

the button.

● Terminate the initialization process using

the button, switch to the P-manual

mode, and correct the actuator travel and

the position displacement sensor.

ok x The permissible measuring range of end po‐

sitions is achieved only in case of a manual

initialization

● Use the button to acknowledge; the

remaining steps ("RUN 1" to "FINSH") run

automatically.

RUN 1 /

ERROR

X Error in "RUN 1", no movement e.g. due to the

lack of compressed air

Possible causes:

● Insufficient supply of compressed air.

● Restrictor(s) blocked.

● Actuator does not move freely.

Measures:

1. Eliminate possible causes.

2. Restart initialization.

d___U X Bar graph display of the zero point is outside

the tolerance range

1. Set between "P 4.0" and "P 9.9" ( >0< )

using friction clutch.

2. Continue using or button.

SEt X Friction clutch was moved; "P 50.0" not dis‐

played when the lever is horizontal

1. In the case of linear actuators, use the

or button to bring the lever

perpendicular to the spindle.

2. Briefly acknowledge using button

(initialization is continued).

MIDDL X

UP > X "UP" tolerance range was exceeded or the in‐

active zone of the potentiometer was covered.

1. Increase the effective lever length of the

linear actuators or switch the transmission

ratio selector to 90°.

2. Briefly acknowledge using button.

3. Restart initialization.

90_95 X Possible only in case of part-turn actuators:

actuator travel is not in the range between 90

and 95%

1. Use the or button to move it in the

range between 90 and 95%.

2. Briefly acknowledge using button.

U-d> X "Up-Down" measuring span was undershot

1. Decrease the effective lever length of the

linear actuators or switch the transmission

ratio selector to 33°.

2. Briefly acknowledge using button.

3. Restart initialization.

Diagnostics and troubleshooting

12.1 Output of system messages in the display

SIPART PS2 with PROFIBUS PA

252 Operating Instructions, 05/2019, A5E00127926-AC

Loading...

Loading...