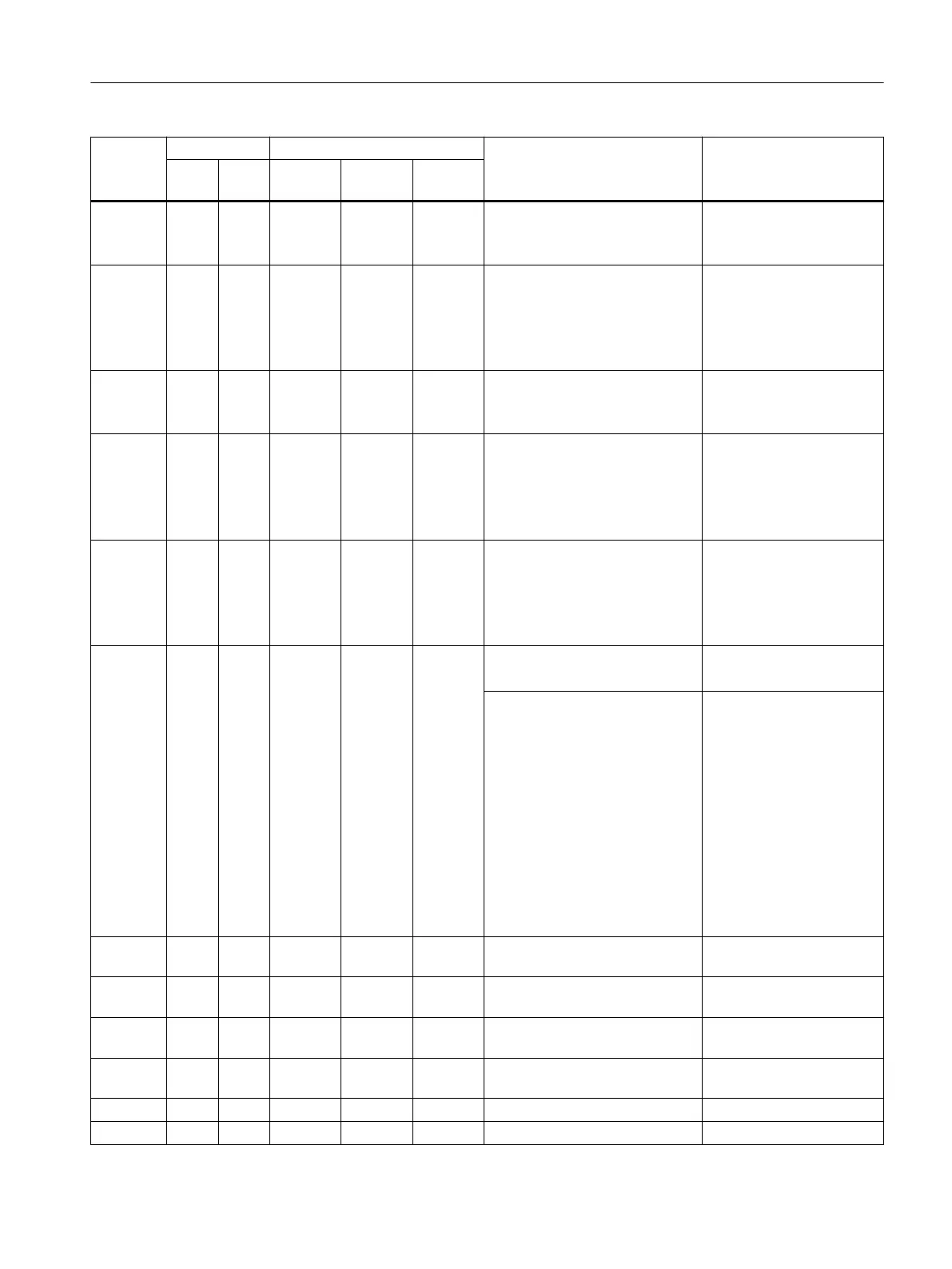

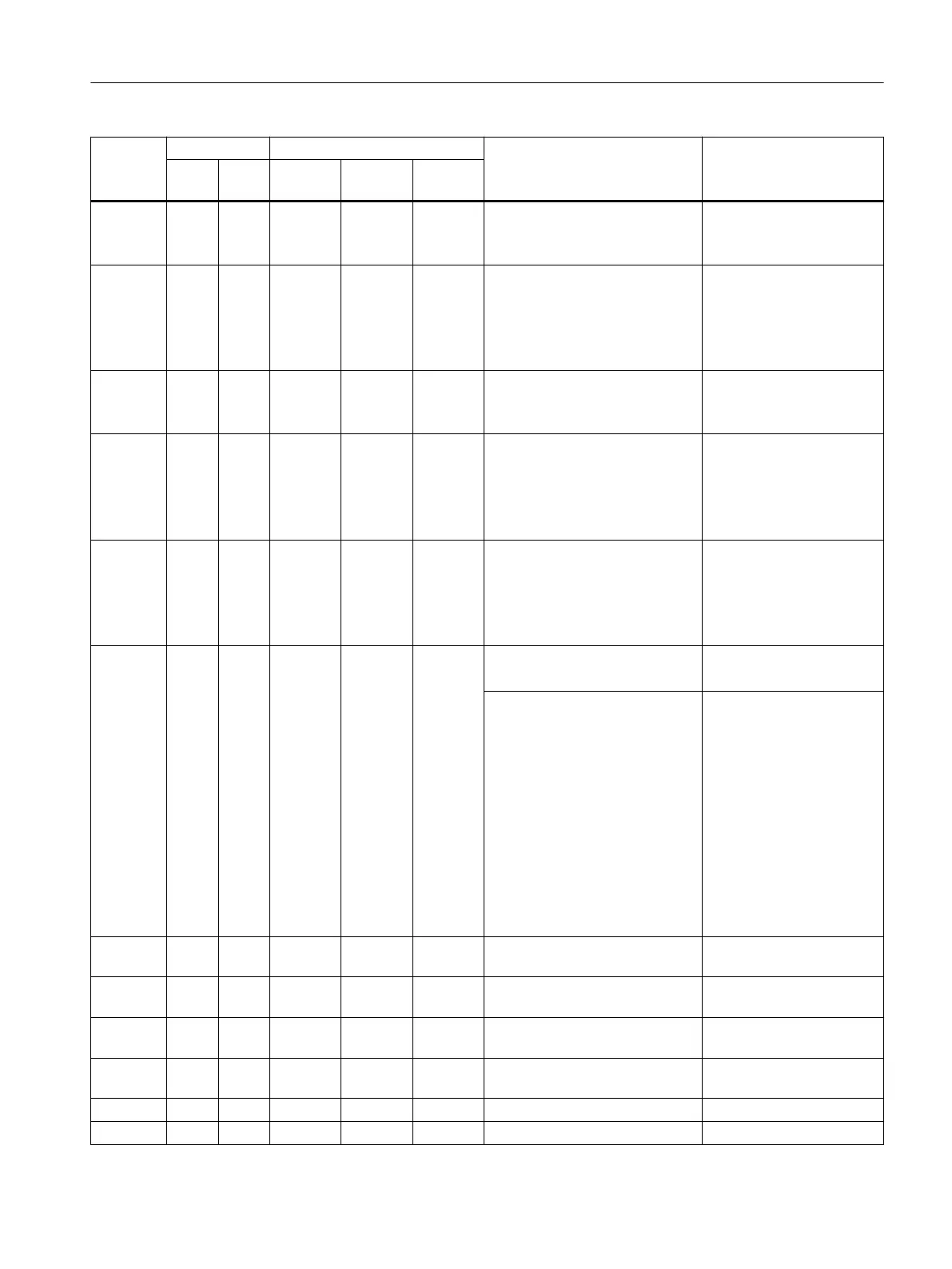

Message Line Operating mode Meaning/cause Measure

Top Bot‐

tom

Automat‐

ic

Manual P-man‐

ual

FS nn X X Controlled using the configured

failsafe position

(Cause: see above).

See above

MM nn X X Positioner is in "Manual" mode.

● Set the target mode

with class-2 master to

"Automatic".

● Send the "0x80" status

(good).

MAnn X Manual mode

(nn = setpoint)

● Switch to automatic

mode using operating

mode button.

LO nn X X Positioner is in "Local override"

mode.

● Set the target mode

with class-2 master to

"Automatic".

● Send the "0x80" status

(good).

OS -- X X X Positioner is in "Out of service"

mode.

● Set the target mode

with class-2 master to

"Automatic".

● Send the "0x80" status

(good).

oFL /

127.9

Display range exceeded.

Possible causes:

● Friction clutch or

● Transmission ratio selector

moved or

● Positioner was installed on a

different actuator without

being reinitialized

● Adjust friction clutch so

that when the actuator

moves, the actual

value display stays

between 0.0 and

100.0, or

● Adjust the

transmission ratio

selector or

● Perform factory

settings (preset) and

initialization

EXSTP X X Actuator was stopped by the bi‐

nary input.

EX UP X X Actuator is moved to the upper

endstop by the binary input.

EXDWN X X Actuator is moved to the lower

endstop by the binary input.

EXPSt The partial stroke test was acti‐

vated, e.g. by a binary input.

InPSt Cyclic partial stroke test.

FST X X Full stroke test running.

Diagnostics and troubleshooting

12.1 Output of system messages in the display

SIPART PS2 with PROFIBUS PA

Operating Instructions, 05/2019, A5E00127926-AC 255

Loading...

Loading...